Why is the sheep manure composting machine environmental protection organic fertilizer equipment? The following content tells you the answer!

Why is the sheep manure composting machine environmental protection organic fertilizer equipment? The following content tells you the answer!

In NPK production line, blender will be used to mix materials. Here is a brief introduction of screw blender.

New type organic fertilizer granulator, that is, the stirring tooth drum granulator, is widely used in organic fertilizer production line. The new type organic fertilizer granulator adopts agglomeration granulation process to make organic fertilizer raw materials into granules, which is convenient for transportation and use of organic fertilizer. It’s core in organic fertilizer production equipment. The equipment has been welcomed by the vast number of organic fertilizer plants.

Windrow turner is a kind of walking compost turning machine. There is no need to build fermentation tank in the process of organic fertilizer fermentation, which can effectively reduce infrastructure investment and increase land utilization.

Characteristics of compost turning machine

Huaqiang fertilizer equipment factory provides a variety of composting equipment, organic fertilizer production process, NPK production line, fertilizer manufacturing machinery.

A large amount of chicken manure is produced every year in the farm, and the appropriate disposal of these wastes can obtain rich benefits. There are many ways to process chicken manure, including physical method, chemical method and microbial fermentation method. The tradition of chicken manure fermentation as fertilizer is to allow it to accumulate and ferment naturally for 5-6 months, which will not only pollute the environment but also cause a lot of nutrient loss. However, composting chicken manure with windrow turner machine using a microbial fermentation method can not only speed up the fermentation process, shorten the fermentation time, prevent waste, but increase the nutritional value of chicken manure. In addition, the temperature produced by fermentation kills insects, saves energy, has low cost, simple operation, and is easy to popularize.

How to solve the problem of organic fertilizer caking has always been a problem for users. The problem of organic fertilizer caking generally occurs in the process of fertilizer processing, storage and transportation. Zhengzhou Tianci Heavy Industry Machinery Co., Ltd. answers this problem in detail to you.

1. Organic fertilizer caking is mainly caused by moisture absorption of micro fertilizer grains, surface dissolution (deliquescence) evaporation and recrystallization. In this process, crystal bridges are formed, resulting in small particles becoming large particles and caking. The caking problem is mainly related to materials (raw materials for fertilizer production), humidity and temperature, small livestock and poultry organic fertilizer production line, external pressure and storage time.

2. The fertilizer production of the organic fertilizer production line is generally non closed production. In the production process, the higher the air humidity is, the easier the fertilizer will absorb moisture and agglomerate. When the weather is dry or the raw materials are dried, the fertilizer is not easy to agglomerate. The higher the room temperature of the extruder granulator is, the easier it is to dissolve. Generally, the raw materials are dissolved in their own crystal water and lead to agglomerate. When the nitrogen temperature is higher, the water evaporates and is not easy to agglomerate.

3. The temperature is generally above 50 ℃, and we usually need to heat to reach this temperature. The greater the external pressure of the fertilizer granulator on the fertilizer, the easier the contact between the crystal and the easier the caking; the smaller the external pressure, the less easy the caking, the longer the placement time of the produced fertilizer, the easier the caking, and the shorter the placement time, the less easy the caking.

Zhengzhou Tianci Heavy Industry Machinery Co., Ltd. adheres to the concept of “honest operation, attentive service” to provide you with high-quality products and services, with an annual output of 1-200000 tons. The local resources, market capacity and market coverage should be taken into account in the production of organic fertilizer. The investment scale and product scheme design of organic fertilizer production line need to be formulated according to the actual situation of customers.

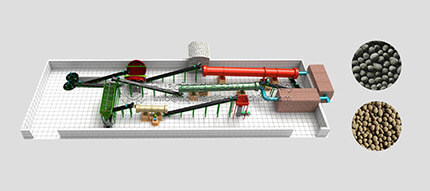

Disc granulation process is simple and relatively cheap. In the organic fertilizer production line, most customers will choose disc granulator. How to improve the pelletizing rate of disc granulator has always been a concern of customers, so how to improve the pelletizing rate of disc granulator? What matters should disc granulator pay attention to when processing organic fertilizer?

Control the moisture content of granulating particles

In the production process of fertilizer granulator, how to preliminarily test the particle water quantity? A simple and practical method, hand feeling method: grasp a ball of materials from the disc granulator, and the hand can form a ball. It is appropriate to release it with a touch of a finger. The grain thus made has high yield and is not easy to block the screen surface.

Strictly control the quality of powder fertilizer

According to the formula of organic fertilizer, carefully control the quality of various raw materials.

Iron block, stone larger than 10 mm and wood block larger than 10 mm are strictly prohibited for raw material discharging and feeding. Rice bran and sand can’t have many quality indexes either, which seriously results in low yield.

Key technology of operating disc granulator

Do well in operator’s technical training of disc granulator, improve workers’ technical quality and operation skills.

Select the nozzle of disc granulator and adjust the nozzle

Generally, B-type spherical screw or B1 type rudimentary spiral nozzle is the best choice for disc feeder.

According to hydrodynamics, it has been proved that the larger the pressure is, the smaller the through hole is, and the larger the droplet diffusion surface is. Under the same pressure, the spray hole of the nozzle is small and the droplet density is small; the spray hole is large and the droplet density is large.

A new type of blade in the disc of the reformed disc granulator

Good blade, even and beautiful grain size, blade material must be 16m, blade is divided into front blade and rear blade, there is no gap between the two blades.

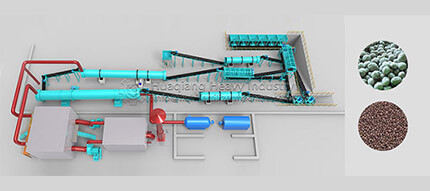

Organic fertilizer production process of sheep dung compost turning machine