How to ferment and granulate manure with organic fertilizer crusher?

The use of cow dung as fertilizer in the planting process is to provide the nutrients needed for crop growth. However, when using cow dung in the planting field, it should be noted that cow dung must be decomposed in the organic fertilizer fermentation tank before being used as organic fertilizer. When it is decomposed at high temperature, it will kill the insect eggs and bacterial viruses in the cow dung. In addition, cow dung can be reused after fermentation and decomposition to avoid burning the roots due to heat.

For the production line of cow manure organic fertilizer, it is recommended to adopt aerobic fermentation treatment. It can be fermented with fermenting agent, which is better for crops. Mix cow manure with straw, sawdust, mushroom residue, etc. in an appropriate proportion (dung accounts for 80-90%, other accounts for 10-20%). 1 ton of material (about 2.5 tons of fresh material) plus 1 kg of fertilizer starter, diluted by 1 kg of fertilizer starter plus 5 kg of rice bran (or bran, corn flour and other substitutes), and then evenly scattered into the material pile. Pay attention to proper oxygen supply and pile turnover during fermentation, and control the temperature at 55-65 ℃. The moisture content of fermentation materials should be controlled at 60~65%.

The method for adjusting the moisture content of materials in the cow manure organic fertilizer production line: the moisture content of fermented cow manure and other livestock and poultry manure should be controlled at 40~65%. Moisture judgment: Grasp a handful of cow dung tightly, see the watermark but do not drip on the finger seam, and it is appropriate to disperse immediately after landing. The fermentation is slow with less water, and the ventilation is poor with more water. Therefore, we must grasp the water content. If the moisture is too high, straw, sawdust, mushroom residue, dry earth powder, etc. can be added. The method to judge whether the moisture is suitable or not: grasp a handful of materials tightly, see the watermark on the finger joint but do not drip, and disperse immediately after landing. Generally, the whole fermentation process can complete the complete deodorization of materials, fermentation maturity, insecticidal sterilization, etc. in 5-7 days.

Technical start-up temperature of cow manure production organic fertilizer production line. The startup temperature should be above 15 ℃ (it can be operated in four seasons, not affected by the season, and try to ferment indoors or in the greenhouse in winter), and the fermentation temperature should be controlled below 70-75 ℃.

Mix well and ventilate. The production of organic fertilizer by cow dung fermentation requires good (consumption) oxygen fermentation. Therefore, the oxygen supply measures should be increased during the operation process, so as to achieve uniform mixing, frequent turnover and ventilation. Otherwise, it will lead to anaerobic fermentation and odor, affecting the fertilizer effect.

Fermentation is complete. Generally, after 48 hours of cow dung accumulation, the temperature rises to 50~60 ℃, and it can reach more than 65 ℃ on the third day. Under this high temperature, it can be overturned once. Generally, there will be two times of high temperature above 65 ℃ in the fermentation process. The fermentation can be completed after two times of overturning, and the fermentation can be completed within a normal week. The material is dark brown, and the temperature begins to drop to normal temperature, indicating that the fermentation is complete.

There are many kinds of organic fertilizer products, among which bio organic fertilizer is a relatively high-grade fertilizer. The production process of bio organic fertilizer with livestock manure is slightly different from that of other fertilizers. The purpose of this process is to protect the microbial bacteria in the process of fertilizer production. The following is a brief description of the production process of this fertilizer with various raw materials.

Organic fertilizer is not only an ideal base fertilizer, but also as topdressing. It is the main fertilizer variety to provide nutrients during crop growth. Attention should be paid to the following matters when organic fertilizer is used as topdressing:

Early application

In China, people’s living standards have been continuously improved, and the problem of food and clothing has been basically solved. High-yield and high-quality agricultural products and hygienic and healthy food have become the urgent needs of the current society and agricultural production.

China’s use of chemical fertilizer ranks first in the world, and the excessive use of chemical fertilizer leads to the decline of the quality of ecological factors in agricultural production. In China, the actual utilization rate of chemical fertilizer is less than 30%. The intensification of excessive use of chemical fertilizer leads to a large reduction of beneficial bacteria in the soil, a decline in soil quality, a reduction in self-purification ability, affecting the yield and quality of crops, endangering human health, and even the risk of environmental retaliation. Hazards of using fertilizer:

1、 Reduce crop productivity

As a result, the soil is hardened, the content of soil organic matter is reduced, the fertility is decreased, and the living space and quantity of beneficial microorganisms in the soil are reduced. The disease resistance, cold resistance, drought resistance and lodging resistance of crops are weakened, and the occurrence of diseases and insect pests is becoming more and more serious, leading to the decline of crop quality and yield.

2、 Aggravate environmental pollution. If too much fertilizer exceeds the soil’s retention capacity, it will flow into the surrounding water, resulting in agricultural water pollution, eutrophication of water body, algae breeding, and then damage the water environment. According to statistics, more than 10 million tons of nitrogen are lost out of farmland every year due to unreasonable fertilization in China, resulting in a direct economic loss of about 30 billion yuan. Excessive fertilizer will also seep into the shallow groundwater within 20 meters, making the nitrate content of groundwater increase.

3、 Waste a lot of scarce resources. If the wasted chemical fertilizer can be saved, the energy shortage in China will be alleviated. In 2004 alone, China’s fertilizer production consumed about 100 million tons of standard coal, more than 5% of the national energy consumption. In addition, China’s fertilizer production consumes more than 100 million tons of high-grade phosphate ore every year, and phosphate ore has been listed in the list of scarce resources by the Ministry of Land and Resources after 2010; Fertilizer production also consumes 72% of China’s sulfur resources.

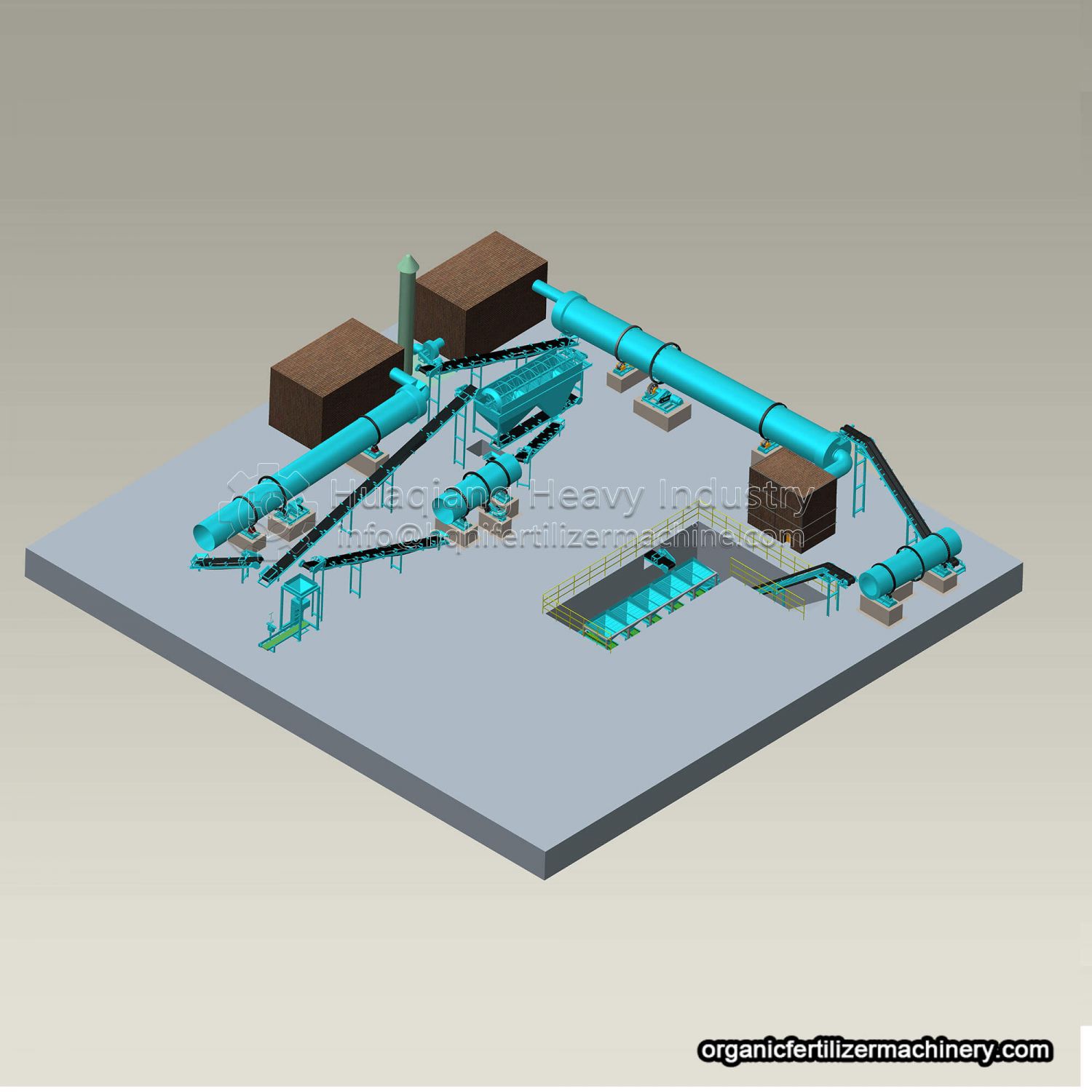

The organic fertilizer production line uses modern microbial technology, mainly livestock and poultry excrement, and bran, peanut shell powder, crop straw and other auxiliary materials as carriers. The bacteria and livestock and poultry excrement are fully mixed by mixing method, so that the microbial bacteria are connected to the livestock and poultry excrement, including dehydrator, fermentation turner, semi-wet material crusher, horizontal mixer, granulator, dryer, cooler, drum screening machine, film coating machine The bio-organic fertilizer produced by packaging equipment, belt conveyor and other equipment after a series of harmless treatment such as rapid heating, fermentation, decomposition and deodorization.

The equipment used in organic fertilizer production line for polishing round particles is called organic fertilizer particle polishing machine. The organic fertilizer granule polishing machine is a new type of ball shaping equipment which is improved on the basis of the traditional granulation. The new round throwing machine realizes continuous feeding and discharging, and improves production efficiency.

The output specifications are different, and the fertilizer granulator machine price is different. Our sheep manure organic fertilizer granulating equipment is used to granulate various organic substances after fermentation. The raw materials do not need to be crushed and dried before granulation. Processed spherical particles can save a lot of energy and break through the conventional organic granulation process.

The use of cow dung as fertilizer in the planting process is to provide the nutrients needed for crop growth. However, when using cow dung in the planting field, it should be noted that cow dung must be decomposed in the organic fertilizer fermentation tank before being used as organic fertilizer. When it is decomposed at high temperature, it will kill the insect eggs and bacterial viruses in the cow dung. In addition, cow dung can be reused after fermentation and decomposition to avoid burning the roots due to heat.

For the production line of cow manure organic fertilizer, it is recommended to adopt aerobic fermentation treatment. It can be fermented with fermenting agent, which is better for crops. Mix cow manure with straw, sawdust, mushroom residue, etc. in an appropriate proportion (dung accounts for 80-90%, other accounts for 10-20%). 1 ton of material (about 2.5 tons of fresh material) plus 1 kg of fertilizer starter, diluted by 1 kg of fertilizer starter plus 5 kg of rice bran (or bran, corn flour and other substitutes), and then evenly scattered into the material pile. Pay attention to proper oxygen supply and pile turnover during fermentation, and control the temperature at 55-65 ℃. The moisture content of fermentation materials should be controlled at 60~65%.

The method for adjusting the moisture content of materials in the cow manure organic fertilizer production line: the moisture content of fermented cow manure and other livestock and poultry manure should be controlled at 40~65%. Moisture judgment: Grasp a handful of cow dung tightly, see the watermark but do not drip on the finger seam, and it is appropriate to disperse immediately after landing. The fermentation is slow with less water, and the ventilation is poor with more water. Therefore, we must grasp the water content. If the moisture is too high, straw, sawdust, mushroom residue, dry earth powder, etc. can be added. The method to judge whether the moisture is suitable or not: grasp a handful of materials tightly, see the watermark on the finger joint but do not drip, and disperse immediately after landing. Generally, the whole fermentation process can complete the complete deodorization of materials, fermentation maturity, insecticidal sterilization, etc. in 5-7 days.

Technical start-up temperature of cow manure production organic fertilizer production line. The startup temperature should be above 15 ℃ (it can be operated in four seasons, not affected by the season, and try to ferment indoors or in the greenhouse in winter), and the fermentation temperature should be controlled below 70-75 ℃.

Mix well and ventilate. The production of organic fertilizer by cow dung fermentation requires good (consumption) oxygen fermentation. Therefore, the oxygen supply measures should be increased during the operation process, so as to achieve uniform mixing, frequent turnover and ventilation. Otherwise, it will lead to anaerobic fermentation and odor, affecting the fertilizer effect.

Fermentation is complete. Generally, after 48 hours of cow dung accumulation, the temperature rises to 50~60 ℃, and it can reach more than 65 ℃ on the third day. Under this high temperature, it can be overturned once. Generally, there will be two times of high temperature above 65 ℃ in the fermentation process. The fermentation can be completed after two times of overturning, and the fermentation can be completed within a normal week. The material is dark brown, and the temperature begins to drop to normal temperature, indicating that the fermentation is complete.

The fermentation quality of organic fertilizer production equipment is directly related to the quality of organic fertilizer production equipment. The production line of organic fertilizer production equipment can help you improve fermentation quality and yield. Compost fermentation uses the oxidative decomposition ability of natural microorganisms to controllably promote the biochemical degradation of degradable organic matter in materials under certain temperature, humidity and pH value to form stable humus. The process can effectively treat organic matter in materials and kill pathogenic bacteria and other harmful substances.

With the modernization of breeding plants, the treatment of livestock manure is becoming more and more diversified. Manure is treated by fertilizer production line in industrialization, and the manure is directly used as high-quality organic fertilizer after professional treatment. Fertilizer granulator, compost turner and other equipment ferment livestock manure into organic fertilizer, which not only protects the environment, but also improves the soil, increases soil fertility, increases crop yield, reduces the amount of chemical fertilizer, and achieves multiple effects with one stroke.

The granulator in the organic fertilizer production line needs maintenance after being used for a period of time. Do you know how to maintain the organic fertilizer processing equipment such as rotary drum granulator? The fertilizer production line needs maintenance, otherwise it may damage the machine if it is used for too long. Organic fertilizer equipment manufacturers will tell you how to maintain it.