As an inevitable product of agricultural production, crop straw is also a very valuable resource. A large number of crop straw is produced every year, but the utilization rate of straw is less than half. A large number of straws were burned on site, which not only caused serious environmental pollution and fire hazards, but also caused a huge waste of resources. Straw fertilizer production line solves the problem of waste reuse.

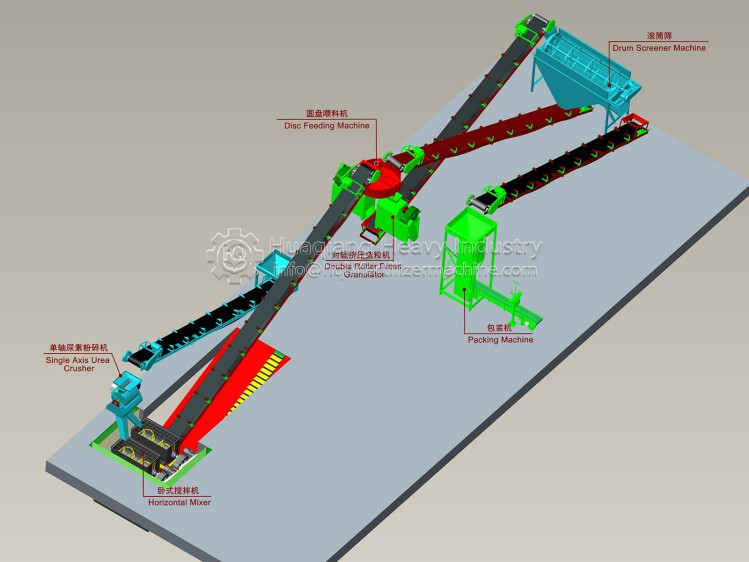

Straw organic fertilizer production line equipment:

Posts from February 2023

What equipment is needed to make cow dung into fertilizer through organic fertilizer production line

Whether or not a cow dung fertilizer machine is worth buying depends on various factors, such as the cost of the machine, the specific needs of the operation, and the potential benefits it can offer.

Some of the benefits of using it are the following:

It can lessen labor expenses and enhance working conditions.

It can generate high-quality fertilizer, which is rich in nitrogen, phosphorous, potassium nutrients that can boost crop yield and soil health.

It can dispose of a significant amount of cow dung in a short amount of time, which makes it more efficient than manual processing.

What equipment is needed to make cow dung into fertilizer through organic fertilizer production line

(1) Measuring equipment The measuring equipment shall have a small scale of 20 kg or less, usually a weighbridge.

(2) The organic fertilizer crushing equipment includes coarse crushing equipment and fine crushing equipment. The coarse crushing equipment is mainly used for crushing before separation, and semi-wet separation crusher is used. Fine crushing equipment is mainly used for the second crushing after separation to meet the requirements of fermentation particle size. Generally, semi-wet crusher (fine crushing) is used.

(3) The sorting equipment is mainly used to remove the non-volatile substances such as plastic, glass, stone and metal in livestock and poultry excrement. The vibrating screen can be used to separate the coarse glass, stone and metal, and the magnetic separator can be used to separate the magnetic metal.

(4) The feeding equipment is used to send the materials to be treated from the storage area or the storage tank to the treatment facilities, which can use conveyor belt, front-end bucket loader, plate feeder, etc.

(5) The mixing equipment mainly adopts twin-screw mixer, disk mixer, etc. The mixed materials are evenly and quantitatively transported to the fermentation equipment after mixing.

Therefore, the cow dung organic fertilizer granulator can consider using extrusion to separate dry and wet substances, making full use of the characteristics of high cellulose content in dry substances to make edible fungus culture medium, such as mushroom culture medium, and then using the substrate after cultivating edible fungus as the material for organic fertilizer production. The fecal water can enter the biogas fermentation to produce biogas, and the fermented residue can be used for composting fermentation to produce organic fertilizer, The fermented water can be directly used for crops, and can also be concentrated to produce liquid organic fertilizer.

Full-automatic pig manure organic fertilizer production line helps farmers increase their income

Small pig manure organic fertilizer production equipment is based on some domestic farms, such as chicken farms, pig farms, cattle farms, and other chicken manure, livestock manure, as raw materials to ferment and produce small amounts of organic fertilizer, to solve the problem that the stink of chicken manure, pig manure, cow manure can not be handled in time, and the equipment price is low, and most farms can accept it.

The development of organic fertilizer equipment is getting faster and faster, especially in recent years, in view of the prominent problems in China’s agricultural production such as excessive use of fertilizer, low efficiency, and declining quality of cultivated land, the main goal of bio-organic fertilizer production equipment is to reduce the use of fertilizer, improve the quality of cultivated land, and realize the industrialization of new and efficient bio-fertilizer.

Individual organic fertilizer equipment configuration includes pulverizers, mixers, granulators, sievers and packers, and small organic fertilizer production line manufacturers. The entire set of equipment is only 50000 to 60000 yuan. The investment in equipment is not large, but a large amount of labor costs need to be invested in the later stage.

The complete set of equipment configuration includes fermentation equipment, pulverizer, mixer, granulator, dryer, cooler, screening machine, coating machine and packaging machine, as well as conveyors for material transportation between equipment. Such a complete set of equipment configuration needs 23 million, but the entire production line only needs five or six workers to complete the production operation and realize automatic production.

When selecting a suitable fertilizer granulation machine, you must know what fertilizer pellet type you want to produce. Maybe you want to have flat ball-shaped fertilizer pellets. Also, you should choose good fertilizer and granules-making plant manufacturers. They can provide professional suggestions, like proper fertilizer granulation equipment maintenance. Remember, maintaining your granulator effectively can prolong your fertilizer pellet mill’s service lifetime.

Why use organic fertilizer production line to produce fertilizer

The production of organic fertilizer still needs to be operated by professional organic fertilizer production line. The chicken manure without fermentation and ripening is used as organic fertilizer after drying, which will ferment and ripen in natural state, which may harm crops and is not conducive to crop growth. Chicken manure into organic fertilizer requires fermentation, ripening, granulation and drying process. After high temperature decomposition, it does not contain harmful bacteria and insect eggs, which avoids the disadvantages of farm manure, such as easy to burn seedlings, odor, and many diseases and insect pests.

Treatment mode of small organic fertilizer production line

Cattle farm uses organic fertilizer production line to process cow manure organic fertilizer

Cattle farm uses organic fertilizer production line to process cow manure organic fertilizer

Now the state strongly supports organic fertilizer agriculture. For some local subsidies and support, cow manure organic fertilizer equipment processing bio-organic fertilizer entrepreneurship is the dream of many farmers. Cattle are anti-pawn animals. Therefore, cattle digest the feed thoroughly. The content of digestible substances such as protein and fat is low in cow dung, mainly crude fiber. Due to complete digestion, the dung is fine and dense, with high water content, difficult to ventilate and low fermentation temperature.

The cow manure organic fertilizer processed by the organic fertilizer production line has many advantages. Here are some examples:

- Improve the soil and make the land fertile. Because cow dung is cold fertilizer, while cattle are herbivores, the content of protein in cow dung is low, and there are many herbaceous fibers. It is suitable for application in fields with serious soil texture damage, which can improve soil permeability and increase soil nutrition.

- Improve crop yield and quality. Organic fertilizer is rich in various nutrient elements such as crude protein, crude fat and crude fiber. After decomposition of organic fertilizer, it can provide energy and nutrients for soil microbial activities, promote microbial activities, accelerate organic matter decomposition, and produce active substances that can promote crop growth and improve the quality of agricultural products.

- To improve the fertilizer utilization rate, organic fertilizer contains a large amount of nutrients, but its relative content is low, and its release is slow, while chemical fertilizer is rich in nutrients, high in composition, low in composition, and fast in release. The application of both is reasonable and complementary. The organic acid produced by the decomposition of organic matter can also promote the dissolution of mineral nutrients in soil and fertilizer.

How to judge the solubility of particles produced by organic fertilizer granulator

After the organic fertilizer is processed by the fertilizer granulator, the fertilizer efficiency of the granular product lasts for a long time and has good solubility. So how to judge the quality of fertilizer products by judging the solubility of particles?

1. Appearance

2. Dissolve with water

3. Judgment of fertilizer efficiency

4. Burn with fire

5. Soil dissolution rate

Use organic fertilizer production line to treat livestock manure and process organic fertilizer

Technical characteristics of chicken manure organic fertilizer production line

Characteristics of chicken manure organic fertilizer:

1、 Because of its short digestive tract, chicken manure contains a large amount of organic matter. Chicken manure is used as organic fertilizer, which has good fertilizer utilization rate and high nutritional value.

2、 In the process of chicken manure fermentation, adding straw and other carbon substances not only improves the permeability of organic fertilizer, but also increases the content of C, which is of great help to crop production and carbon cycle.

3、 Chicken manure organic fertilizer has risen rapidly to reach the nutritional level of organic fertilizer without adding foreign fungicides and nutrients.

Technological characteristics of chicken manure organic fertilizer production line:

(1) The process of small chicken manure organic fertilizer equipment consists of raw material pretreatment system, fermentation system and fertilizer processing system, which can be flexibly combined according to the treatment capacity:

(2) The fermentation system adopts forced ventilation dynamic fermentation to ensure the adaptive supply of oxygen during the fermentation process, maintain the high activity and efficiency of microorganisms, and the product quality is stable. The general period is 15 days, and the aging period is 20 days. Compared with the traditional composting period of 60 days, the efficiency is obvious;

(3) The products of the small-scale chicken manure organic fertilizer production line project are highly harmless, with a removal rate of more than 99%, and completely decomposed. At the same time, the characteristics of raw materials are brought into play, and special products and market-specific fertilizers are developed according to the characteristics of local regions. The small-scale chicken manure organic fertilizer equipment meets the needs of marketization. The chicken manure organic fertilizer production line can be processed into refined fertilizer, improve output and increase efficiency, and promote pollution-free production. If chicken manure can be processed into organic fertilizer, it can not only effectively use chicken manure resources, but also not worry about sales.

Fermented chicken manure can be used directly as fertilizer or as raw material to produce compound organic fertilizer, which can thoroughly solve the environmental pollution problem caused by livestock manure and carcasses, and ensure the large-scale, green and sustainable development of the aquaculture industry.

Commercial organic fertilizer is a kind of fertilizer processed by organic fertilizer production line

The commercial organic fertilizer sold on the market is a kind of fertilizer which has been treated by the fertilizer production line. It has eliminated the harm and can be used directly. Animal manure can not be directly used as organic fertilizer in the soil, which will cause great harm to the soil. Therefore, it is suggested to purchase organic fertilizer processed by fertilizer granulator, which is convenient and efficient.

1. Acidification of soil can induce various rhizosphere diseases and virus diseases

Technological characteristics of fertilizer production by organic fertilizer granulator

Judging from the characteristics of the organic fertilizer granulator equipment itself, it has the advantages of low power, quick results, low investment, and good economic benefits. In addition, the granulator has low production cost, safe and reliable equipment operation, advanced technology, stable operation, and convenient maintenance. The layout of the fertilizer production line we designed according to the user’s site needs is reasonable, which is suitable for environmental protection promotion projects.

Process principle of organic fertilizer granulator machine for making granular fertilizer