Dry pig manure contains crude protein 10%-20%, crude fat 1%-3%, nitrogen-free extract 20%-30%, crude fiber 15%-30%, so it has high nutrients. Studies have found that dried pig manure can be fermented into high-quality organic fertilizer products. Can fluff the soil, improve soil compaction, chelate trace elements in the soil, improve soil fertility, etc. Pig manure is the most used raw material in the fertilizer production process.

Matters needing attention during pig manure fermentation:

Raw material particle size: The particle size of pig manure and auxiliary raw materials must be less than 10mm, otherwise it needs to be crushed;

Suitable material moisture: the optimum fermentation humidity for composting microorganisms is 50-60%, and the limit humidity is 60-65%. Therefore, it is best to adjust the material moisture to about 55-60%. When the moisture reaches more than 65%, there is a higher chance of dead tank without fermentation. Fermentation of pig manure generally requires the help of compost windrow turners, which can make your work faster.

Control of pig manure and auxiliary materials: According to local agricultural conditions, organic materials such as straw, corn stalks, and peanut stems can be used as auxiliary materials. The ratio of pig manure and auxiliary materials can be adjusted according to the requirements of fermentation water. (Generally 3:1), the composting auxiliary materials can choose the raw materials with a carbon to nitrogen ratio of 20~80:1. Therefore, the common dry straw, corn stalks, fallen leaves, soybean stems, peanut stems and other organic matter can be used as auxiliary materials for composting and fermentation after being crushed.

Fermentation cycle: After pig manure, auxiliary materials and inoculum materials are mixed in the tank, the first time is turned over, which is recorded as the start time of the fermentation cycle. Generally, it enters the high temperature fermentation stage after 3 to 4 days of heating period (5 to 7 days in winter). Take the temperature as the standard. When the temperature of the pile body exceeds 60-70℃, keep it for more than 24 hours, and the pile can be turned over. The number of times of turning the pile varies with season. The summer fermentation period is generally 15 days, and the winter fermentation period is 25 days.

If 10 days after entering the tank, it is found that the temperature in the fermentation tank has not exceeded 40°C, it can be judged as a dead tank and fermentation start-up failed. At this time, the moisture in the tank must be measured. If the moisture exceeds 60%, supplementary materials and inoculation materials need to be added; if the moisture is less than 60%, consider whether the amount of inoculation materials is insufficient.

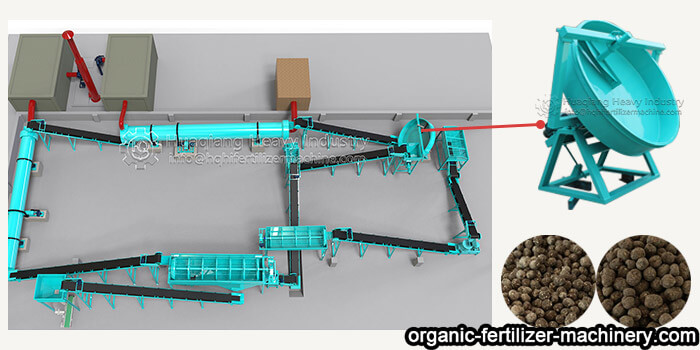

We not only have a complete set of organic fertilizer machine, but also a complete set of compound fertilizer machine.

.jpg)

.jpg)

.jpg)