The equipment for the chicken manure processing organic fertilizer production line is not fixed as we imagine, but needs to be determined based on the site and materials. Therefore, the chicken manure processing organic fertilizer production line equipment configured for each customer is different. If producing powdered organic fertilizer for processing, only one fermentation equipment, crusher, and screening machine, needs to be invested. The investment is just tens of thousands of yuan (based on production volume and equipment selection).

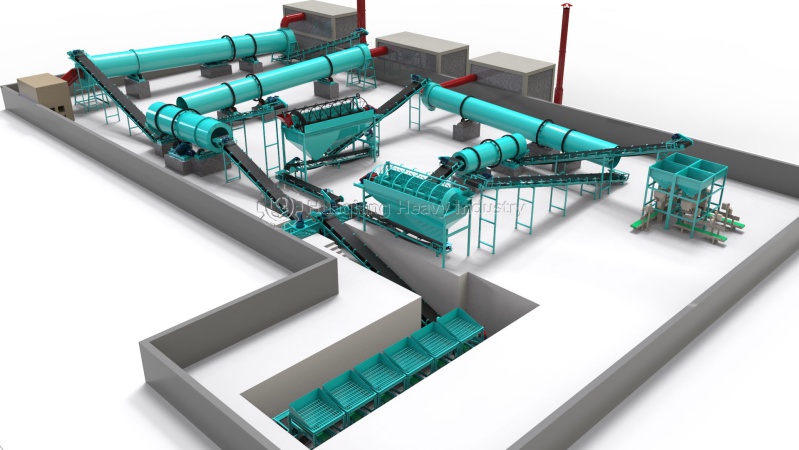

The entire set of small-scale chicken manure processing organic fertilizer production line equipment only requires fermentation equipment, crushers, mixers, granulators, screening machines, and packaging machines with low configuration. This belongs to the basic configuration, and devices are added according to the actual needs and requirements of the customer. Therefore, the price of the entire set of organic fertilizer production line equipment for chicken manure processing ranges from tens of thousands to hundreds of thousands.

.jpg)

1. Determine the size of organic fertilizer equipment, such as the annual production of tens of thousands of tons or the hourly production of tons, in order to determine the price.

2. Determining the shape of the particles means choosing what kind of granulator to use: powder, cylindrical, flat spherical, or standard circular. The commonly used equipment for granulating organic fertilizers includes: disc granulator, drum granulator, wet granulator, roller extrusion granulator, flat mold granulator, and ring film granulator. The selection of granulators should be determined based on the local fertilizer sales market. The particle shape is different, the process of organic fertilizer equipment is also different, and the price of organic fertilizer equipment is also different.

3. Determine the configuration level of organic fertilizer equipment: The configuration level varies, the price of organic fertilizer equipment varies, and the amount of labor used varies. The stable and high production of organic fertilizer equipment also varies. Generally, higher configurations need to be added, including automatic batching device, automatic packaging device, automatic quantitative feeding device, cyclone dust removal with water and dust removal.

4. Determine the type of fertilizer to be produced. It is a compound fertilizer organic fertilizer equipment or an organic fertilizer organic fertilizer equipment. For the same yield, organic fertilizer organic fertilizer equipment generally considers high moisture content and the strain is not resistant to high temperatures. The model is generally larger than the compound fertilizer model. There are generally four types of organic fertilizers, including pure organic fertilizer, organic-inorganic compound fertilizer, bio organic fertilizer, and compound microbial fertilizer. The equipment for organic fertilizers varies slightly depending on the variety.

5. Selection of fermentation flipper: The general fermentation forms include stack fermentation, shallow tank fermentation, deep tank fermentation, tower fermentation, and rotary drum fermentation. The fermentation methods and equipment for organic fertilizer fermentation are different. Generally, a shallow groove turner is more suitable for aerobic fermentation principles (the advantages of a shallow groove turner are that it is more in line with the principles of aerobic fermentation, is not easy to form anaerobic, has complete and complete fermentation, and has a fast fermentation speed).

6. Determine the level of environmental protection requirements: In areas with low environmental requirements, heavy dust removal is generally chosen, and the investment in organic fertilizer equipment is relatively low; Places with high environmental requirements generally choose heavy dust removal and ink dust removal, which can meet the national air emission quality standards.

.jpg)

.jpg)

.jpg)