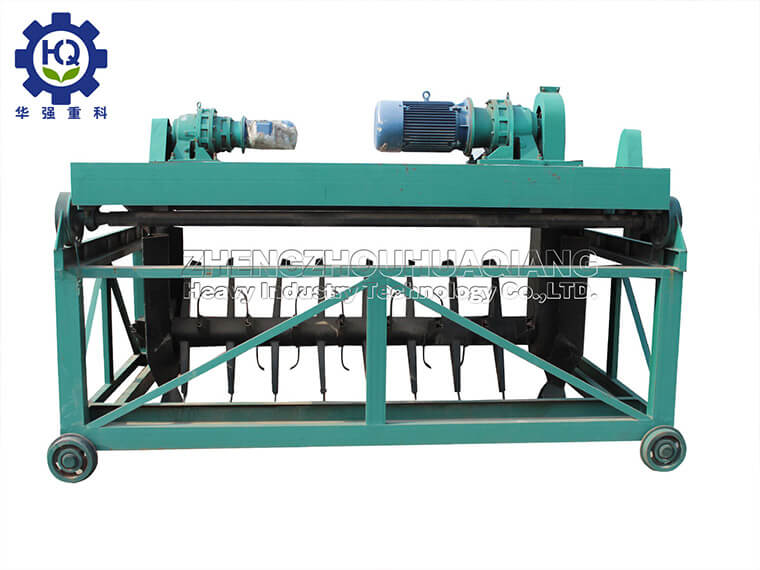

Organic fertilizer Dumper: directly pile the materials into strips, and use a wheeled dumper to turn and ferment in a straddle manner. Tank fermentation is adopted. According to your production scale, you need to build 1-5 fermentation tanks with a width of 3M and a length of 40-60m. The fermentation products are continuously put into the fermentation tank and tossed and fermented by the tossing machine, which can achieve the purpose of water regulation, uniform mixing, deodorization and dehumidification, which can not only save a lot of labor, but also achieve the purpose of full ripening;

1, performance: when we buy fermentation compost turning machine, we must first see its performance, to see whether the performance is stable and safe, regardless of the operation of any organic fertilizer equipment must be safe first, the performance of a device depends on whether the equipment can be used for a long time, and will greatly affect the life of the organic fertilizer production line.

2, processing capacity: In order to determine the required throughput of the fermentation compost turning machine, the volume of the compost per week must be used for turning at the peak available time. The throughput of a particular lathe is determined by the speed of its working stroke and the size of the pile it can handle. Powerful machines generally have greater throughput rates because they handle larger piles.

3, the field capacity: the processing is wider, especially the higher pile to accommodate the material of the given larger volume pile fertilizer pile the turning worker thinks the required aisle space by the turning worker. Self-driven lathes require less aisle space than tow models.

4, material: The material used by a good manufacturer has a good fiber content and a smaller viscosity of yeast light, it can use compost fermentation turning machine has a strong crushing and stirring function. Therefore, it can save the pretreatment process of raw materials by mixing and crushing thereby reducing the production process and the fermentation rate of the advancing material. To make the material more uniform and loose. For sewage treatment plants that filter mud and other colloidal sludge sludge who have sticky functions, soft pile turning point composting fermentation turning machine should be used. Therefore, it enables more rapid water loss and then shortens the fermentation time.

5, cost: because of the size of the machine, speed, strength and characteristics of the development. Consider the purchase cost relative to processing volume and capacity. The higher cost performance of large tossing machines means that the compost volume is larger.

.jpg)

.jpg)