The raw materials for compound fertilizer include urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate, monoammonium phosphate, diammonium phosphate, heavy calcium, superphosphate, and other raw materials. These raw materials have the advantages of reasonable granulation, high nutrient content, few by-products, and good physical properties. They play a very important role in balancing fertilization, improving fertilizer utilization efficiency, and promoting high and stable crop yields. What equipment is needed for the production of compound fertilizer besides the roller extrusion granulator?

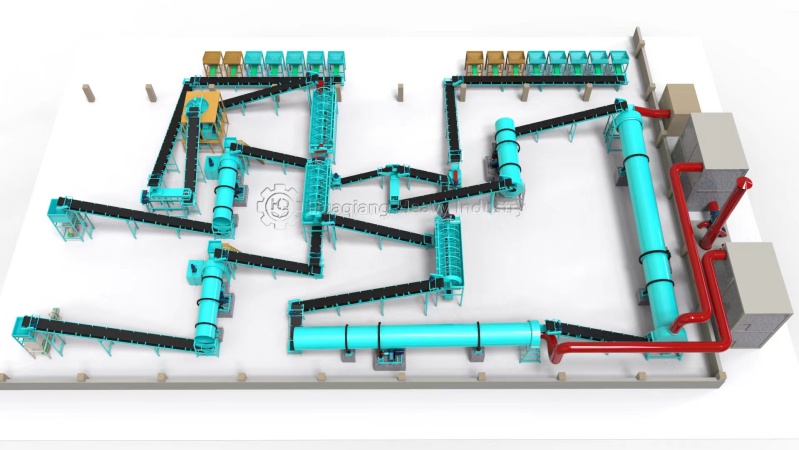

What other supporting equipment are needed for compound fertilizer granulation besides the roller extrusion granulation machine? The roller squeezing granulator is the main equipment for granulating powder material composite fertilizers. In addition to the roller squeezing granulator, it also requires a fully automatic batching machine, a mixer, a vertical crusher, a drum screening machine, a dryer, a cooling machine, a secondary drum screening machine, and an automatic packaging scale. The equipment is connected by a belt conveyor.

The twin roll squeezing granulator utilizes paired rolling rolls with adjustable gaps between them, which rotate in opposite directions at the same speed. The surface of the rolling mill is regularly arranged with many arc grooves of the same shape and size. According to the different compression ratios of the material object, it is selected to use the groove of one rolling mill to align exactly with the groove of the other rolling mill. The two rolling rolls are in a horizontal parallel state, and the powder like material is continuously and uniformly fed between the two rolling rolls by its own weight and forced feeding from above. When the material enters the biting area, it is gradually bitten by the rolling rolls. With the continuous rotation of the rolling rolls, the space occupied by the material gradually decreases and is gradually compressed, reaching the maximum value of the forming pressure. Then, the pressure gradually decreases, resulting in clumps, Due to the elastic recovery and the weight of the rolled sheet, the arc groove of the rolling roller falls off. Next, it enters the cutting device and is screened into granular products.

The layout of the complete set of compound fertilizer production equipment is compact, scientifically reasonable, and technologically advanced. No discharge of three wastes, stable operation, reliable operation, and convenient maintenance. Wide adaptability of raw materials, suitable for granulation of various raw materials such as compound fertilizers, pharmaceuticals, chemicals, feed, etc. The product has a high granulation rate and a small footprint. It can produce various concentrations and types of compound fertilizers (including organic fertilizers, inorganic fertilizers, biological fertilizers, magnetized fertilizers, etc.).

.jpg)

.jpg)