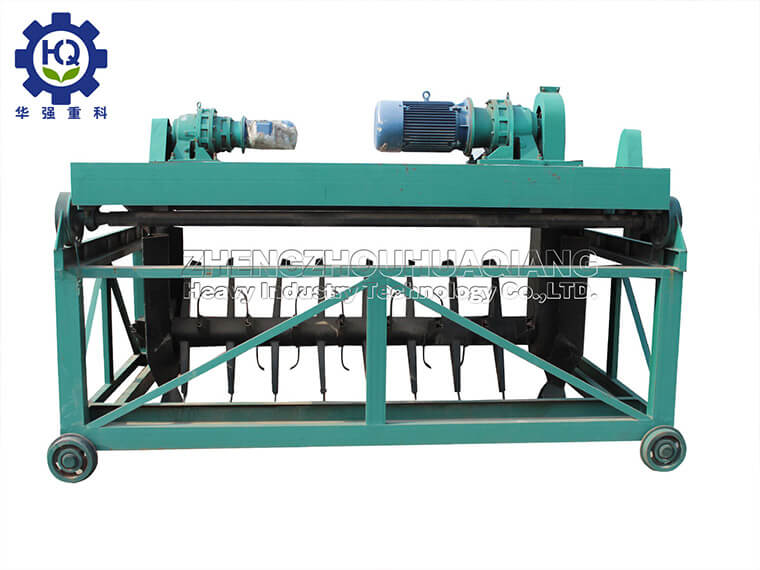

The slot type tipping machine is suitable for fermenting and flipping organic waste such as agricultural and animal husbandry, animal manure, sludge and garbage, filter sludge from sugar factories, residue cake, and straw sawdust. The slot type tipping machine is widely used in organic fertilizer plants, compound fertilizer plants, sludge disposal sites, horticultural fields, and mushroom cultivation sites for fermentation, maturation, and water removal operations.

The slot type composting machine is the core equipment of aerobic dynamic composting. As a new type of efficient machine that replaces manual labor and forklifts for material flipping, it is the mainstream product that affects the development trend of the composting industry.

The role of tank type composting machine in agricultural and animal husbandry machinery fermentation equipment (in composting production):

1. Mixing function in raw material conditioning. In fertilizer production, some auxiliary materials must be added to adjust the carbon to nitrogen ratio, acidity, water content, etc. of the raw materials. The main raw materials and various auxiliary materials roughly stacked together in proportion can be stirred by a stacker to achieve uniform mixing and tempering.

2. Mediate the temperature of the raw material pile. During the operation of slot type composting machine, the raw material pellets are fully in contact and mixed with the air. The material pile can contain a large amount of fresh air, which helps aerobic microorganisms to actively produce fermentation heat and increase the pile temperature; When the temperature rises, the replenishment of fresh air can lower the reactor temperature. Forming a state of alternating between medium temperature, high temperature, medium temperature, and high temperature, various beneficial microorganisms grow and reproduce in the temperature range they adapt to.

3. Improve the permeability of raw material piles. The flipping system can process materials into small clumps, making the sticky and dense material pile fluffy and elastic, forming a suitable porosity.

4. Adjust the moisture content of the raw material pile. The suitable moisture content for raw material fermentation is around 55%, and the moisture standard for finished organic fertilizer is below 20%. During fermentation, biochemical reactions generate new water, and the consumption of raw materials by microorganisms also causes water to lose its carrier and free up. Therefore, with the process of fertilizer production, timely reduction of water content, in addition to evaporation formed by thermal conduction, the flipping of raw materials by the flipping machine will form forced water vapor emission.

5. Special requirements for achieving composting technology. For example, crushing raw materials, giving the raw material pile a certain shape, or achieving quantitative displacement of raw materials.