The future development potential of organic fertilizer production lines is enormous. Due to the current agricultural situation in China, organic fertilizer raw materials are abundant and of high quality, and the market demand for organic fertilizer is also large. The scale of use of organic fertilizer is also very wide, whether it is farmland or vegetable cultivation greenhouses, or the beautification of fruit trees, flower gardens, and soil improvement, organic fertilizer is widely used. It also conforms to the national agricultural development policy, indicating that the prospect of organic fertilizer production lines is very broad.

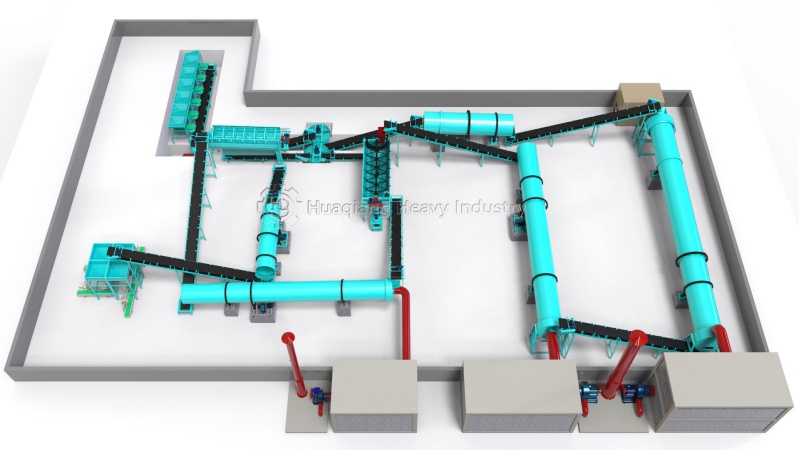

The organic fertilizer production line is composed of many small machinery and equipment, each of which affects, restricts, and complements each other. After a certain process flow, high-quality organic fertilizer can be processed. The production process of the organic fertilizer production line is as follows:

1. The raw materials, auxiliary materials, and fermentation agents are pre mixed evenly through the equipment in proportion, with a moisture content of about 60. They are transported by conveyor belts and distributed to the fermentation tank through shuttle belt distribution machines.

2. In order to fully ferment the materials in the fermentation tank, a chain plate tipping machine is used to flip and shift the materials. At the same time, the aeration system is used to aerate the bottom of the tank, allowing the materials to undergo aerobic fermentation.

3. The fermentation of the material is basically completed in the fermentation tank for about 7 to 10 days. Under the flipping displacement of the flipping machine, the material is flipped to the discharge end, and then transported to the aging tank through the pool changing discharge machine, discharge belt machine, and shuttle type distribution machine for secondary fermentation of aging, so that the material is thoroughly decomposed.

4. The decomposed materials are transported to the granulation workshop through conveyor belts, and are screened and processed by drum screening machines and vertical crushers to remove large pieces of material;

5. The screened materials and other inorganic nutrients are proportionally transported to a dual shaft paddle mixer using a batching belt scale for mixing. Uniformly mixed materials can be packaged as powder products, and can also be granulated by adjusting the moisture content to around 40.

6. Materials with a moisture content of about 40% are produced into columnar semi-finished products through a granulator, which are then shaped into spherical granular semi-finished products through a shaping machine. They are transported by a conveyor belt to a tubular dryer for low-temperature drying, and then screened and cooled by a cooling screening machine to reduce the moisture content to between 15 and 30. They can also be coated and packaged as needed;

7. The finished particles are transported to the packaging workshop through bucket elevators and finished product conveyor belts, and are packaged using automatic measuring packaging scales and manually stacked.

The construction of an organic fertilizer production line has a market opportunity. Nowadays, people are pursuing a high-quality life, and their pursuit of food quality is also increasing. Under the strong call of national policies, more and more farmers are applying organic fertilizer, which has a long-lasting effect and contains various nutrients that crops need. Maintaining fertilizer and water can also prevent and control diseases and pests. The small organic fertilizer production line has a very broad profit margin and is an ideal project.