The drum granulator uses low-humidity agglomeration granulation to increase the granulation temperature to increase the amount of liquid in the basic material, which promotes the material to form pellets at a lower water content. It has the advantages of easy drying, energy saving, and consumption reduction.

The drum granulator adopts a unique design: the material particles can directly collide with each other. With a wide range of applications and no special requirements for materials, it is widely used in large-scale organic fertilizer production lines and npk compound fertilizer production lines. In addition, it can directly produce organic fertilizer to eliminate the need for pre-drying and crushing. Spherical particles of particles. High granulation rate, drum organic fertilizer has a good appearance.

The granulation process of the drum granulator increases the temperature and viscosity of the material through the use of steam, so that the water content of the material can be reduced during the pelletizing process, thereby reducing the drying load, and the liquid phase distribution of steam is comparable to that of water Evenly. Only when the liquid phase of the material is insufficient and the material is unstable, add water as a supplementary means. During the production process, we have encountered improper installation of steam nozzles and uneven distribution of the liquid phase of the material, causing the material where there is more liquid phase to stick into large balls, and where the liquid phase is insufficient, the material is difficult to ball, which affects the formation of particles. In view of this situation, we can increase the steam nozzle to increase the steam receiving area of the material.

Author: fertilizer production line

The granulation technology of drum granulator in organic fertilizer production line

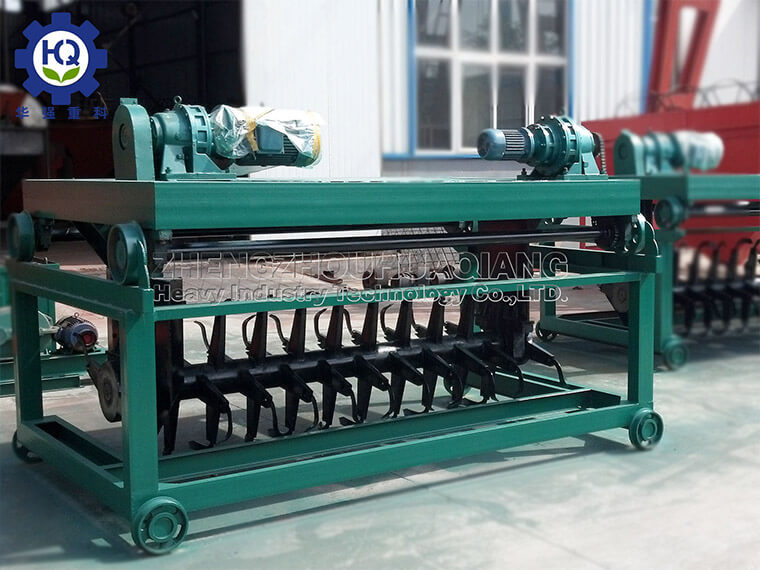

The working principle of the rotary drum stirring tooth combined granulator uses the high-speed rotating mechanical stirring force and the resulting aerodynamic force to continuously realize the mixing of the fine powder in the machine, granulation, spheroidization, extrusion, collision, and densification, polishing and other processes, so as to achieve the purpose of granulation. The shape of the particles produced by this organic fertilizer granulator machine is spherical, the sphericity is ≥0.7, the particle size is generally between 0.3-3 mm, and the granulation rate is ≥90%. The size of the particle diameter can be appropriately adjusted by the mixing amount of the material and the spindle speed. , Generally, the lower the mixing amount, the higher the speed and the smaller the particles.

The new rotary drum stirring tooth combined granulator produces bacteria at room temperature and has a reasonable structure design. It can produce spherical type granular products. The produced granules have low water content, easy drying, high forming rate, good granule strength, and beautiful appearance. It is the ideal granulating equipment for bio-organic fertilizer, organic-inorganic fertilizer, organic fertilizer and inorganic compound fertilizer.

The scope of application of the new type combined stirring tooth drum granulator: After fermentation treatment of organic waste such as peat, sludge, chicken manure, livestock manure, lignite, sugar factory filter sludge, paper sludge, wine, straw, bean dregs, grass charcoal, etc. It can be directly granulated, which completely solves the key technical problems that are difficult to solve by the traditional disc (rotating drum) granulation process, fermentation, etc., and granulates the raw material of bio-organic fertilizer.

The Process Characteristics of Organic Fertilizer Fermentation and Piling Machine for Cow and Sheep Manure

If you want to raise chickens, you need to be environmentally friendly. What should you do with chicken manure in a chicken farm? Where should we go? The slot type tipping machine can use a transfer truck to perform multiple slot operations in one machine. High yield, small land area for flipping, material flipping, and reduced moisture during the fermentation process, stable equipment operation, and extremely low failure rate, making it an ideal equipment for chicken manure fermentation treatment in chicken farms.

The cow and sheep manure organic fertilizer fermentation and tipping machine is commonly referred to as a guide rail type tipping machine. It can be used for fermentation and composting of organic waste such as livestock and poultry manure, sludge waste, sugar factory filter mud, residue cake, and straw sawdust. It is widely used for fermentation and moisture removal operations in organic fertilizer plants, compound fertilizer plants, sludge waste plants, horticultural fields, and mushroom cultivation plants.

1. High efficiency, stable operation, sturdy and durable, even flipping and throwing. The control cabinet is centrally controlled and can achieve manual or automatic control functions. The process of treating chicken manure and urine is also the process of fermenting bacteria to ripen, and the overturning and stirring of the 4-meter trough compost flipper in the chicken farm can not only increase air circulation, but also achieve rapid decomposition, dehydration, and fertilization of chicken manure and urine.

2. The tooth extraction is sturdy and durable, and the stacking material has certain crushing and mixing functions. The use of ectopic fermentation by the 4-meter trough compost flipper in the chicken farm can not only effectively save the land resources occupied by breeding, but also achieve reasonable utilization of land resources by expanding the scale of the chicken farm!

3. The fermentation tank of the slot type tipping machine is a reinforced concrete structure, and two adjacent fermentation tanks share the same tank wall. The width of the pool wall is determined according to the requirements of the throwing machine. The pool wall should be able to withstand the pressure of the tipping machine, and the bottom plate of the fermentation tank should not only bear the gravity of the fermentation material but also the gravity of the loader, while also meeting the requirements of ventilation.

The technology and advantages of drum granulator in processing fertilizers

Because the NPK compound fertilizer raw material has certain corrosiveness, the inner wall of the cylinder is easy to be corroded, thus shortening the service life. And the viscous material is easy to adhere to the inner wall, reducing the granulation efficiency.

Drum granulator is one of the key equipment in NPK compound fertilizer industry, which is suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizer. The main working mode is wet granulation. Through a certain amount of water or steam, the basic fertilizer can be fully chemically reacted after being humidified in the cylinder. Under a certain liquid phase condition, with the help of the rotary movement of the cylinder, the extrusion force between the material particles can be produced to agglomerate into pellets.

The drum granulator produced by our company is welded with high-quality medium carbon steel plate, with built-in special rubber lining or acid resistant stainless steel lining, which realizes automatic scar removal and tumor removal, cancels the traditional scraper device, and achieves the purpose of this machine through strict quality control and special process requirements.

The main advantage of the drum granulator is that it uses steam to heat the humidity, which increases the temperature of the granulated material itself, reduces the granulation moisture, reduces the load of the dryer, and improves the work efficiency. The pelletizing rate of the drum pelletizer can reach 70%, and the equipment is easy to operate, flexible in work, and easy to maintain.

Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. mainly produces organic fertilizer machines: disc granulator, npk fertilizer granulator, double roller granulator, organic fertilizer granulator machine, drum granulator, flat die pelleting machine, and ring die pelleting machine, vermicelli machine, fertilizer mixer machine, fermentation compost turning machine, coating machine, packaging machine, etc., and sells 1-200000 NPK fertilizer production line, organic fertilizer production line, bio organic fertilizer production line, BB fertilizer complete equipment. Our products are energy-saving, convenient, environmental protection and efficient, and have reached the leading level of the same industry in the world. Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. has a superb technical team, domestic and foreign first-class partners, scientific and standardized customer training system. We look forward to cooperating with you!

Application scope and granulation process of disc type organic fertilizer granulator

It is well known that organic fertilizer occupies an important position in organic agriculture, but the development of organic fertilizer is also a slow process. Containing any chemical ingredients, then the organic fertilizer granulator machine comes in handy. Many people do not understand the purpose and characteristics of the disc fertilizer granulator. In fact, the disc granulator is used to granulate various organic matter after fermentation, breaking through the conventional organic matter granulation process. There is no need to dry and crush the raw materials before granulation, and the spherical particles can be processed directly by the ingredients, which can save a lot of energy.

The disc granulator uses the cohesive force of the material itself to rotate in an inclined disc to make the material stick together little by little, so that the material becomes granules. This granulation method is relatively simple. This kind of granulation method requires material moisture at 50-60%, and we consume a lot of drying for all this. The requirements for materials are relatively high, and some materials with poor adhesion are not easy to be made into pellets.

The disc granulator is an ideal choice for organic fertilizer plants, feed plants, farms and livestock plants, sewage treatment plants, towns, towns, villages, and farmers to start businesses. The fertilizer granulator has the advantages of beautiful appearance, simple operation, low energy consumption, long life, high granulation rate, strong granule roundness, intuitive operation and convenient maintenance.

Scope of application and fermentation advantages of chicken manure crawler tipping machine

Crawler type stacker is a type of large stacker, with a fully hydraulic operating system, a pull rod steering wheel operation, and a tracked walking system. The stacker can reach a width of up to 3 meters and a height of up to 1.5 meters. It uses a diesel engine as the power, with four wheels running. The power is transmitted through the transmission system to the drum carrying the combined cutting tools for operation. It fills a gap in the inability of large wheeled tipping machines in China to turn around in place.

The crawler type tipping machine is suitable for aerobic fermentation and tipping of organic waste such as livestock and poultry manure, sludge waste, sugar factory filter mud, and straw sawdust; Widely used in fermentation and moisture removal operations in organic fertilizer plants, compound fertilizer plants, sludge and garbage plants, and mushroom cultivation plants.

Advantages of large chicken manure crawler tipping machine:

1. This machine has reliable performance, easy operation, and strong field applicability, which can be carried out in open outdoor fields or in workshop greenhouses.

2. This machine does not need to build a trough, and can directly pile fertilizers into long strip piles on the ground. The material is regularly mixed and crushed by the tipping machine, and organic matter is decomposed under oxygen consumption conditions.

3. This machine adopts a design of overall lifting and lowering of the frame, which can lift and lower the frame height when changing the work site and the height of the pile.

After a series of treatments by a large chicken manure crawler tipping machine, the feces can not only be thoroughly fermented, but also reduce the fermentation time of traditional composting from 2-3 months to only 15 days, greatly improving the fermentation efficiency and treatment capacity of the feces, turning the original fecal waste into highly efficient organic fertilizer that can be reused.

Application of Drum Granulator in NPK Compound Fertilizer Production Line

The drum granulator is a method of mixing and granulating powdered basic fertilizers, and is widely used in the granulation of npk compound fertilizers. The principle of npk compound fertilizer drum granulator:

The material forms a rolling material bed by the friction generated by the rotation of the drum granulator. The squeezing force generated by rolling makes the material containing a certain liquid phase agglomerate into small particles. These small particles become the core and adhere to the surrounding powder. Form larger particles. Since the drum granulator is generally inclined 1°~2.5° to the discharge end, the pellets slowly roll toward the discharge port while rotating with the cylinder. Qualified pellets leave the drum granulator and then enter the dryer for drying, and then go through screening, cooling, coating, packaging and storage. After being crushed, the on-screen material and the under-screen material are sent to the hopper as the return material and the basic fertilizer is granulated at the same time.

The function of the rotary drum npk fertilizer granulator is to pre-granulate the powdery material in the cylinder to form tiny particles with a diameter of 1 to 2 mm. The granulation effect of the drum granulator will directly affect the ball formation rate and product quality.

The drum npk fertilizer granulator effectively prevents the problem of a large amount of powder from flowing out with the granular material, reduces the processing volume and return volume of the subsequent drying, cooling, and screening equipment, and reduces the power consumption of the subsequent equipment. It has a good economic benefit.

The roller extrusion granulator is a key equipment for compound fertilizer granulation, with advanced technology, reasonable design, compact structure, novel and practical, low energy consumption, and matching with corresponding equipment to form a small production line, which can form a certain capacity of continuous and mechanized production. Adopting the eugenic formula, without drying, produced at room temperature, the product is rolled and formed in one go, ensuring that the product quality meets the technical requirements of compound fertilizers. It is an updated product for the production of high, medium, and low concentration specialized compound fertilizers for various crops and the energy-saving and consumption reduction of the compound fertilizer industry.

The granulation principle and process of a new type of organic fertilizer granulator

The new organic fertilizer granulator machine uses the high-speed rotating mechanical stirring force and the resulting aerodynamic force to continuously realize the process of mixing, granulating, spheroidizing, and densification of the fine powder in the machine, so as to achieve the purpose of granulation. The particle shape is spherical, the sphericity is ≥0.7, the particle size is generally between 0.3-3 mm, and the granulation rate is ≥90%. The particle diameter can be appropriately adjusted by the mixing amount of the material and the spindle speed. Generally, the lower the mixing amount, the speed The higher the particle size, the smaller the particle size and vice versa.

Production line process of new organic fertilizer granulator machine

The production line process of organic fertilizer granulator includes compost turning machine, fertilizer mixer machine, crusher, rotary drum granulator, particle dryer, particle cooler, coating machine for finished product, and quantitative packaging machine for finished product.

Organic fertilizer raw materials (animal manure, domestic garbage, dead branches, rotten leaves, biogas residues, waste bacteria, etc.) are fermented into a semi-wet material pulverizer for pulverization, and then elements such as nitrogen, phosphorus and potassium (pure nitrogen, phosphorus pentoxide, phosphorus pentoxide, etc.) are added. Potassium chloride, ammonium chloride, etc.) to make the contained mineral elements reach the required standard, then a mixer is used to stir, and then enter the new organic fertilizer granulator machine to granulate, after it is dried, it is sieved by a sieving machine, and qualified products are packaged , The unqualified return to the granulator for granulation.

The working principle and advantages of a small pig manure composting and fermentation overturning machine

Pig manure organic fertilizer fermentation equipment, also known in the industry as tipping machines, throwing machines, and pig manure organic fertilizer fermentation bacterial agents. The fermented pig manure organic fertilizer is transported by forklift to the semi-finished product warehouse, and then onto the pig manure organic fertilizer equipment for fully automated assembly line production. The pig manure organic fertilizer equipment includes a crushing process, screening process, granulation process, drying, cooling process, particle screening process, and finally to the packaging process, which is connected by a belt conveyor. Nowadays, there are a large number of pig farming enterprises in various regions, and with this, pig manure resources are also very abundant. Utilizing this large amount of pig manure to produce organic fertilizer solves the major problem of environmental pollution, while also producing a large amount of pig manure organic fertilizer. The economic benefits are also very considerable.

The small pig manure composting and fermentation tipping machine adopts a ground tank structure, which can be designed according to the factory structure to use a series of fermentation products with multiple tanks. It has the characteristics of simple operation, short fermentation cycle, sufficient fermentation, small pollution, and convenient expansion. Our company’s organic fertilizer tank type tipping machine has a lifting function, which is easy to adjust the flipping depth, flexible operation, and convenient power for operation.

The pig manure organic fertilizer composting machine is mainly used for the fermentation and composting of organic waste such as livestock and poultry manure, sludge waste, sugar factory filter mud, residue cake, and straw sawdust. It can also be widely used for the fermentation and moisture removal operations in organic fertilizer plants, compound fertilizer plants, sludge and garbage plants, horticultural farms, and mushroom planting plants. Suitable for aerobic fermentation and can be used in conjunction with fermentation tanks and transfer machines. It can achieve the function of multiple slots for one machine when used in conjunction with a transfer machine. The fermentation tank matched with it can both continuously discharge and batch discharge. High efficiency, stable operation, sturdy and durable, even flipping and throwing.

The granulation process of drum granulator on organic fertilizer production line

The granulation mode of drum granulator is a kind of agglomeration process with rolling growth, which provides many potential benefits for the processors of bulk solid materials. This paper summarizes the working principle of agglomeration granulation of drum granulator and the important factors that must be considered.

Granulation is a form of agglomeration (particle size increase) for the production of round particles, which is a valuable operation in the treatment of bulk solids. This technology provides many possible improvements in the treatment, appearance, application and performance of a variety of solid materials.

The granulation process of rotary drum granulator is a form of ball agglomeration, which can be highly customized, and can be used to produce spherical particles conforming to specific specifications.

The granulation process is usually carried out in a drum granulator, followed by a drying step and possibly other processing steps.

Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. adheres to market orientation, innovation and development, quality and survival, and perfect after-sales service to win the trust of customers. We mainly produce organic fertilizer granulator machine, crusher, mixer, conveyor, compost windrow turner, coating machine, packaging machine, dryer, cooler, screening machine, as well as different types of fertilizer production lines, including organic fertilizer production line, bio organic fertilizer production line, NPK fertilizer manufacturing process, BB fertilizer production line. Warmly welcome people from all walks of life to visit the company, mutual benefit, win-win, create a better!