In the production of organic fertilizers, bio-fertilizers, and organic-inorganic compound fertilizers, granulation is a crucial process that gives the product its commercial form, improves application convenience, and enhances market value. Among numerous granulation equipment, the disc granulator, with its classic structure, intuitive operation, reliable operation, and outstanding cost-effectiveness, has always occupied a core position in small and medium-sized fertilizer production lines. Huaqiang Heavy Industry, combining years of technological research and development with project practice, provides an in-depth analysis of the application advantages, precise operation points, and systematic capacity optimization strategies of the disc granulator.

Core Advantages: Why Choose a Disc Granulator?

The advantages of the disc granulator stem from its ingenious working principle: well-mixed powdered materials are continuously fed into an inclined rotating disc, where, under the combined action of gravity, centrifugal force, and friction between materials, they continuously roll, agglomerate, and grow, ultimately forming uniform granules.

High pelletizing rate and excellent granule quality: Under mature process control, the pelletizing rate can typically be consistently maintained above 80%. The produced granules have good roundness, smooth surface, and excellent product appearance.

Easy to operate and maintain: The equipment structure is relatively simple, the operating principle is intuitive, and the technical requirements for operators are moderate. There are few daily maintenance points, and maintenance costs are significantly lower than some more complex models.

Highly adaptable and flexible: Particularly suitable for small-to-medium batch, multi-variety production, with convenient product formula switching. Good compatibility with organic materials, microbial agents, trace elements, and other additives.

Excellent cost-effectiveness: Under the same capacity requirements, its equipment purchase cost and subsequent energy consumption are usually more economical, making it an ideal choice for startups and cooperatives.

Precise Operation: Mastering Three Core Parameters While the disc granulator is “easy to use,” mastering its “effective use” hinges on the precise and coordinated control of three key process parameters: disc inclination angle, rotation speed, and raw material moisture content.

Disc Inclination Angle (typically 35°-55°): The inclination angle directly affects the residence time and rolling trajectory of the material within the disc. If the tilt angle is too large, the particles will roll off before they have grown sufficiently, resulting in a smaller particle size; if the tilt angle is too small, the particles will remain in the disk for too long, potentially causing overgrowth or even clumping. Fine-tuning is necessary based on material characteristics and the target particle size.

Disc rotation speed (typically 20-40 r/min): The rotation speed determines the magnitude of the centrifugal force on the material. Too high a speed will cause the material to be thrown towards the edge of the disk, resulting in insufficient rolling, irregular particles, and excessive powder; too low a speed will result in insufficient material lifting height, inadequate rolling, slow pelleting, and a wide particle size distribution.

Raw material moisture content (typically 25%-45%): Moisture acts as a “binder” for pelleting. Too low a moisture content will make it difficult for particles to form, resulting in more powder; too high a moisture content will cause the material to easily clump together, forming large pellets or causing a paste-like substance in the disk. Moisture content needs to be adjusted in conjunction with the amount of binder (such as bentonite or lignin sulfonate).

To reduce operational complexity, Huaqiang Heavy Industry’s intelligent disc granulator integrates a sensor and PLC control system, enabling real-time monitoring and automatic adjustment of tilt angle and speed for more stable and efficient production.

III. Capacity Optimization: Achieving Dual Improvement in Efficiency and Quality

To fully realize the equipment’s potential, system optimization across the entire production process is necessary:

Raw Material Pretreatment is Fundamental: Ensure the material entering the granulator meets the required fineness (ideally 80 mesh or finer) and is absolutely uniformly mixed (mixing uniformity coefficient of variation CV < 5%). Uniform and fine powder is the core prerequisite for forming uniform granules.

Scientific Selection of Binders: Given the poor binding properties of pure organic raw materials, scientifically adding an appropriate amount of binder is key to improving granule strength (reducing breakage rate) and one-time pelletizing rate. The optimal type and addition ratio must be determined through experimentation based on the raw material composition.

Maintaining Optimal Equipment Condition: Regularly (e.g., every shift or daily) clean the inner wall of the disc and the scraper of any adhering material to prevent hardening of accumulated material that alters the disc’s internal contour and affects material rolling patterns. Check the scraper wear to ensure it effectively cleans the bottom of the disc.

Standardized Operations: For mature products, the optimal combination of tilt angle, rotation speed, and feed rate should be determined and solidified through testing to form a Standard Operating Procedure (SOP) to ensure consistency across different shifts.

Case Study: Significant Benefits of Optimization A large agricultural cooperative in China adopted a φ2.2-meter disc granulator and a complete optimization solution provided by Huaqiang Heavy Industry when producing organic-inorganic compound fertilizer. Through refined raw material crushing and mixing, precise control of granulation humidity, and strict regular cleaning and maintenance, the production line’s capacity steadily increased from the designed 5 tons/hour to 7 tons/hour without major equipment modifications, and the granule qualification rate (particle size range and strength) remained above 90% for a long time. This not only directly increased output value but also significantly reduced the unit product production cost and enhanced market competitiveness by reducing rework rate and energy consumption.

Conclusion: The Modern Value of Classic Equipment As a timeless classic piece of equipment, the disc granulator’s value continues to be renewed with the support of intelligent control and systematic process optimization. For the vast majority of small and medium-sized fertilizer production enterprises, a deep understanding of its working principle, mastery of the key parameters, and comprehensive production management will enable them to stably and efficiently produce high-quality fertilizer products with this “economical and practical” equipment, thus winning their own place in the market competition.

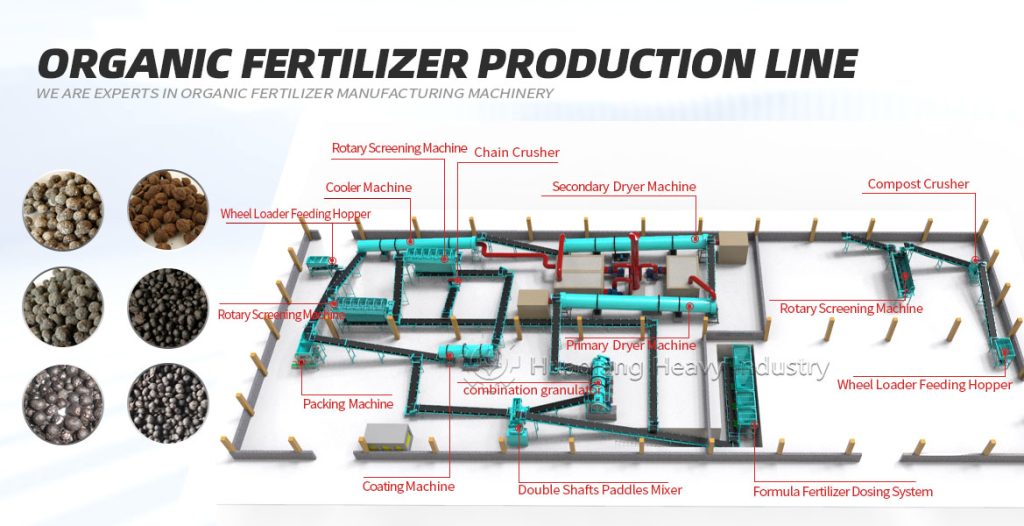

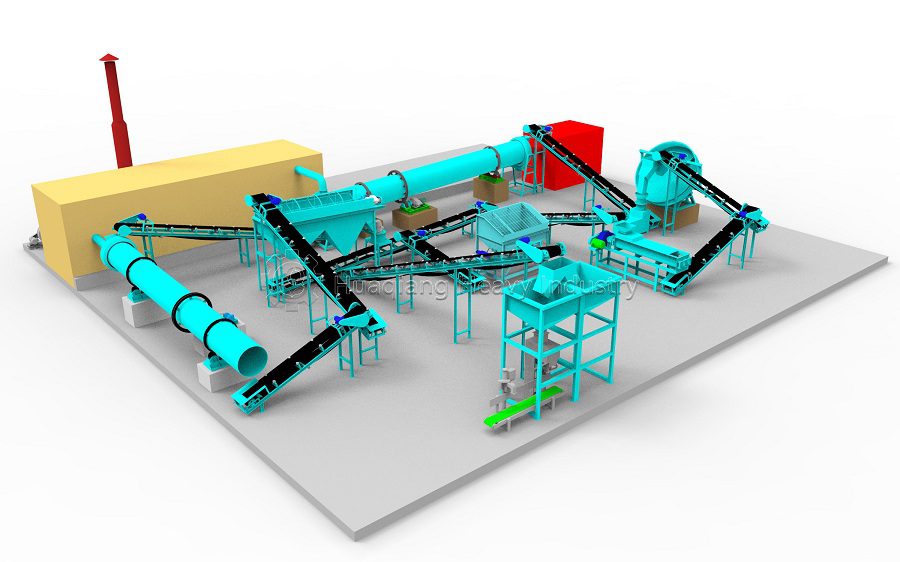

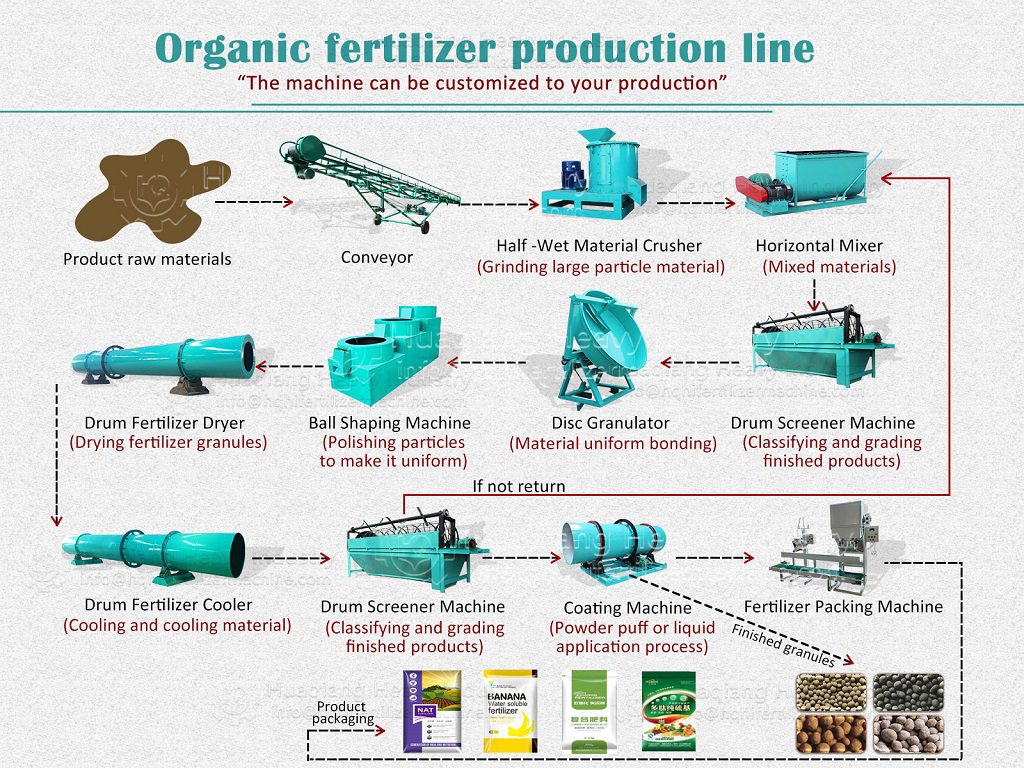

Positioning Disc Granulation within Integrated Manufacturing

The disc granulator is a key piece of professional fertilizer manufacturing equipment within specific production lines. Its primary role of disc granulator for shaping is often employed in an organic fertilizer production line or a bio organic fertilizer production line, where it gently forms spherical pellets from moist organic powders. However, its application is not universal. For the mainstream npk fertilizer production process, high-volume production is often achieved using a rotary drum granulator. Alternatively, a double roller press granulator is chosen for dry compaction granulation. The choice depends on the material’s characteristics and production goals.

A complete npk fertilizer production line typically begins with precise batching using a npk bulk blending machine and other fertilizer raw material processing machinery and equipment. If a wet granulation method similar to disc granulation is chosen for NPK, a larger-scale rotary drum is often used instead. Thus, a disc granulation production line is specifically advantageous for small-to-medium scale organic or compound fertilizer production where gentle agglomeration and flexibility are prioritized over extreme high capacity.

Therefore, understanding the strengths and ideal applications of the disc granulator allows manufacturers to strategically integrate it into a broader equipment portfolio, selecting the optimal granulation technology for each product type and scale within a diversified operation.