How much is the full set of organic fertilizer production line equipment for aquaculture farms? An annual production capacity of approximately 200000 to 400000 tons of organic fertilizer production line equipment; An annual production of 30000 to 50000 tons of organic fertilizer production line equipment is approximately 400000 to 800000 yuan; An annual production of 100000 tons of organic fertilizer production line equipment is approximately 1.8-5 million; This also depends on the process you choose. The production line has differences between granules and powders, and the price of granules is slightly higher than that of powders.

The construction plan for small organic fertilizer plants allows organic fertilizer products to be made into granules or powders, depending on market demand. In order to balance nutrients and be suitable for transportation and storage, it is recommended to process organic fertilizers into granules. Granular fertilizers have good commercial properties and do not automatically grade during storage and transportation. They have slow-release properties and can create a granular structure for the soil..jpg)

The powdered organic fertilizer organic fertilizer production line requires the purchase of equipment such as fermentation tipping machines, crushers, packaging machines, etc. The equipment investment is between 80000 to 150000 yuan.

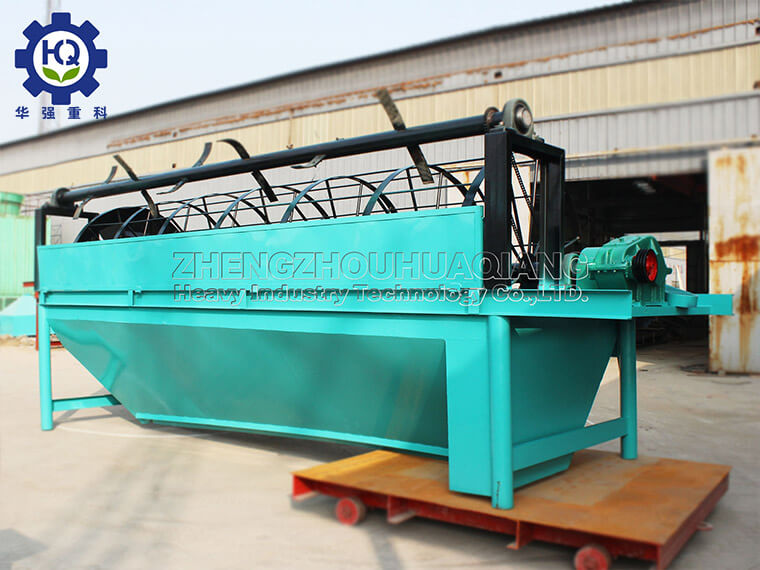

The production line of granular small organic fertilizer mainly consists of fermentation and tipping equipment, drying system, deodorization and dust removal system, crushing system, ingredient system, mixing system, granulation equipment, and finished product packaging system; The fermentation system for harmless treatment of livestock and poultry manure includes: feed conveyor, biological deodorizer, mixer, flipper, oxygen supply system, and automatic control system. The equipment investment is between 150000 to 450000 yuan. There are many types of equipment for manufacturing organic fertilizers, and different plans for organic fertilizer production lines need to be developed based on customer materials and output.

The current complete set of organic fertilizer production line equipment for aquaculture farms does not require a large amount of investment, and can achieve multi-year returns with just one investment. This is also the reason why many forward-looking investors prefer it, especially for small-scale production lines that are more suitable for smaller farms and can create a circular ecological chain. It is recommended to choose a large-scale organic fertilizer equipment manufacturer, which can provide site and factory planning and design, installation and debugging, and formula production of finished products.

.jpg)

.jpg)

.jpg)