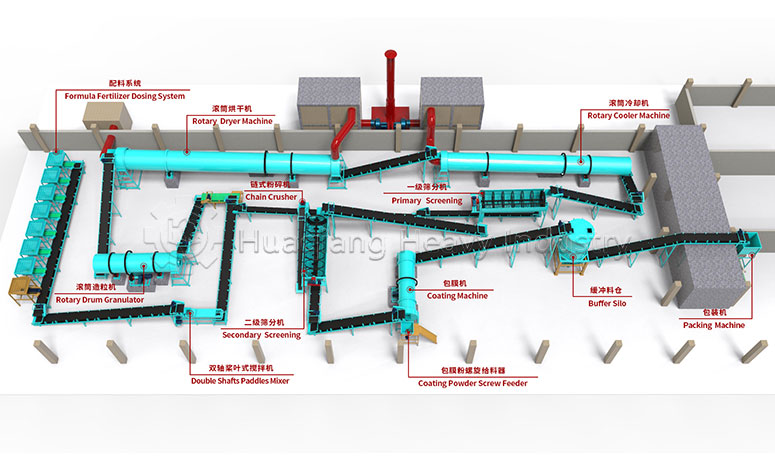

NPK fertilizers are essential nutrients for crop growth, but excessive levels can trigger a chain reaction of harmful effects. If the NPK fertilizer production line lacks precise control, or if the fertilizer crusher and fertilizer mixer are operated improperly during raw material processing and mixing, it can easily lead to excessive NPK content in the finished product.

For crops, excessive NPK levels can lead to abnormal growth and reduced quality. Excess nitrogen can cause excessive vegetative growth, weakened resistance to disease and pests, and delayed maturity; excessive phosphorus and potassium can cause nutrient antagonism, hindering the absorption of micronutrients, leading to leaf deformities, flower and fruit drop, and reduced fruit taste and nutritional value.

For the soil, long-term application of high-content NPK fertilizers can disrupt the soil ecosystem, leading to soil acidification and compaction, and reduced aeration; excessive phosphorus accumulation can cause soil eutrophication, inhibit microbial activity, gradually degrade soil fertility, and affect long-term cultivation.

For the environment, unabsorbed nutrients are washed away by rainwater, polluting surface and groundwater and causing water eutrophication; nitrogen volatilization can also pollute the air, creating agricultural non-point source pollution and disrupting the ecological balance.

In summary, NPK fertilizer application must follow the principle of precise proportioning. NPK fertilizer production lines must strictly control nutrient ratios, and other fertilizer production equipment must be operated properly, taking into account crop quality, soil health, and the ecological environment.