It mainly consists of several steps in the organic fertilizer production process, including grinding, composting and granulation. The first step in crushing is to crush the raw material. Oil palm empty fruit string should be cut into silk. The optimum length was 3cm, which increased the silk surface area, improved the fermentation speed and shortened the fermentation time. The shell can be cut into particles 3-10mm in size. Oil palm leaves should be chopped as much as possible. In this process, semi-wet material crusher is suitable for the crushing of these materials. It can meet the need for efficient and short blending of palm oil waste..jpg)

Compost

It is the whole organic fertilizer production key link. During the fermentation process, a compost machine can be used to ferment the material completely. It is best to control the temperature between 60-75℃ during the composting process. The pH value should be between 5.5 and 8.5. When the final fermentation of the material is completed, the moisture content is completely controlled at 35%.

Fermentation

The fermentation time was affected by fermentation temperature, fermentation rate and water content. Fermentation temperature should be suitable for composting. Too much or too little heat is bad for composting. In the fermentation process, the moisture content of the material should be fully controlled so that the material can achieve rapid fermentation. Palm oil waste should also be turned a reasonable number of times. Turning too many times not only increases labor costs, but also accelerates the evaporation of water from the material to some extent, thus affecting the compost.

Granulation

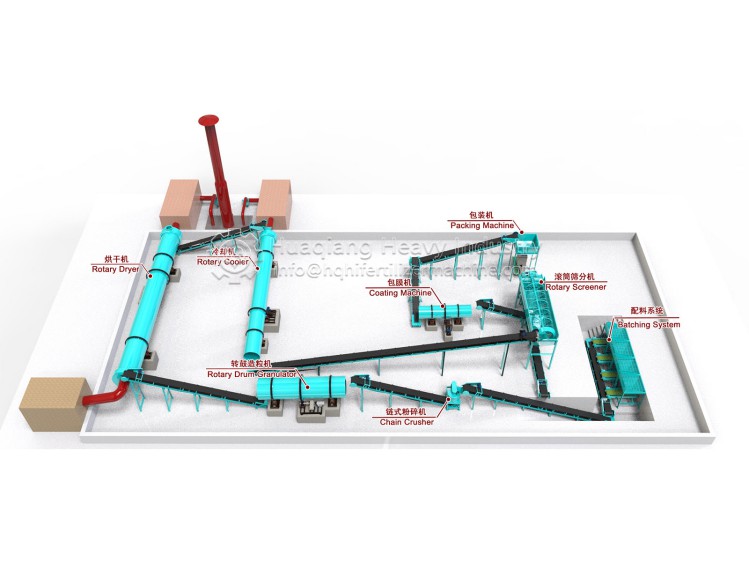

After composting, granulation can be carried out according to different needs. According to the test data of the complete fermentation raw material, a small amount of inorganic substances, including N, P, K, Ca, Mg, are added to make it meet the standard of organic fertilizer raw material or meet the use demand of oil palm varieties organic fertilizer plantation. It is then produced into pellets by a fertilizer granulator. They are cylindrical particles with a diameter of 0.8-10cm. Extrusion granulator can improve the effect of granulation, so that the granularity of granulation to achieve the best. After composting and granulation are complete, they can be dried, cooled and screened. Materials should be dried and cooled after granulation. It should be kept dry, which makes organic fertilizer easy to preserve. Finally, the organic fertilizer is packaged.

.jpg)

.jpg)

.jpg)