As an inevitable product of agricultural production, crop straw is also a very valuable resource. A large number of crop straw is produced every year, but the utilization rate of straw is less than half. A large number of straws were burned on site, which not only caused serious environmental pollution and fire hazards, but also caused a huge waste of resources. Straw fertilizer production line solves the problem of waste reuse.

Straw organic fertilizer production line equipment:

Author: fertilizer production line

How to determine the project scale of organic fertilizer production line according to the output

Organic fertilizer production line is a good investment project for many people now, because organic fertilizer equipment is not only in line with the development trend of environmental protection, but also a kind of practical agricultural machinery. Fertilizer granulator manufacturers lead you to understand how to determine the project scale of fertilizer production line.

Organic fertilizer production line processes organic fertilizer instead of chemical fertilizer

Green agriculture will promote organic fertilizer production line to process chicken manure and replace chemical fertilizer with organic fertilizer

For chicken farmers, it is a headache to deal with dirty and smelly chicken dung, while for organic fertilizer production line processing plants, chicken dung is a treasure. After the chicken manure is fermented and processed by organic fertilizer equipment, it is processed into organic fertilizer, which has become a hot commodity for growers. Now the state strongly supports organic fertilizer agriculture. For some local subsidies, chicken manure organic fertilizer production equipment processing bio-organic fertilizer entrepreneurship is the dream of many farmers. Chicken dung has been regarded by industry experts as a high-quality organic fertilizer raw material.

Organic fertilizer tipping machine equipment ferments chicken manure:

1、 Prepare faeces for fermentation. Chicken dung contains a large number of bacillus, which is aerobic fermentation bacteria. If natural breeding is adopted, the heating time will be prolonged, so it can be considered to add fermentation bacteria or use reflux to accelerate the heating speed.

2、 Construction pile of chicken dung: the height of the prepared chicken dung should not be too short and the volume should not be too small while spreading the bacteria. Requirements: the pile height should be 1.5~3 meters, the width should be based on the type of dumper, and the length should take into account the fermentation cycle, plant size, local climate and other factors. The larger the pile, the higher the fermentation in winter, especially in cold areas.

3、 Adjust moisture. The moisture content of fermented chicken manure should be controlled at 40 ≤ 65%. Moisture judgment: hold a handful of pig dung tightly, and see the watermark instead of dripping with your fingers. It is appropriate to fall on the ground. Slow water fermentation and poor water ventilation will also cause “anaerobic bacteria” to work and produce odor. Therefore, the water content must be controlled.

4、 Starting temperature. The starting temperature should be above 5-15 ℃ (it can be operated in four seasons, and is not affected by the season, winter indoor or greenhouse fermentation), and the fermentation temperature should be controlled below 70-75 ℃.

5、 Mix and breathe. The fermentation of chicken manure should be good (consumption) oxygen fermentation. Therefore, oxygen supply measures should be increased in the operation process to make mixing, frequent rotation and ventilation appropriate, otherwise anaerobic fermentation and odor will occur, which will affect the effect of fertilizer.

6、 Fermentation is complete. Generally speaking, after 48 hours of chicken manure accumulation, the temperature rises to 50 ℃ and 60 ℃, and the temperature can reach 65 ℃ on the third day. It can be turned over once at this high temperature. Generally, after more than 20 days of fermentation, the temperature drops to a certain level, and then it can age.

Use professional organic fertilizer production line to produce fertilizer

The production of organic fertilizer still needs to be operated by professional organic fertilizer production line. The chicken manure without fermentation and ripening is used as organic fertilizer after drying, which will ferment and ripen in natural state, which may harm crops and is not conducive to crop growth. Chicken manure into organic fertilizer requires fermentation, ripening, granulation and drying process. After high temperature decomposition, it does not contain harmful bacteria and insect eggs, which avoids the disadvantages of farm manure, such as easy to burn seedlings, odor, and many diseases and insect pests.

Treatment mode of small organic fertilizer production line

How to properly maintain the organic fertilizer granulator in chicken farms

Organic fertilizer equipment produces organic fertilizer and develops ecological agriculture

To develop ecological agriculture and develop and produce pollution-free “organic food”, the fertilization technology in agricultural production must be reformed, that is, to apply fertilizer reasonably, to follow the development path of organic-inorganic combination application, and to vigorously develop organic fertilizer. Benefits of using organic fertilizer:

1、 Improve soil and improve soil fertility: after applying organic fertilizer into the soil, organic matter can effectively improve the physical and chemical conditions and biological characteristics of the soil, ripen the soil, enhance the ability of fertilizer conservation and supply and buffer capacity of the soil, and create good soil conditions for the growth of crops.

2、 Improve product quality and increase yield: organic fertilizer is rich in organic matter and various nutrient elements to provide nutrition for crops. After the decomposition of organic fertilizer, it can provide energy and nutrients for soil microbial activities, promote microbial activities, accelerate the decomposition of organic matter, and produce active substances that can promote the growth of crops and improve the quality of agricultural products.

3、 Improve the utilization rate of fertilizer: organic fertilizer contains a lot of nutrients and releases slowly. The organic acid produced by the decomposition of organic matter can also promote the dissolution of mineral nutrients in the soil, which is conducive to crop absorption and improve the utilization rate of fertilizer.

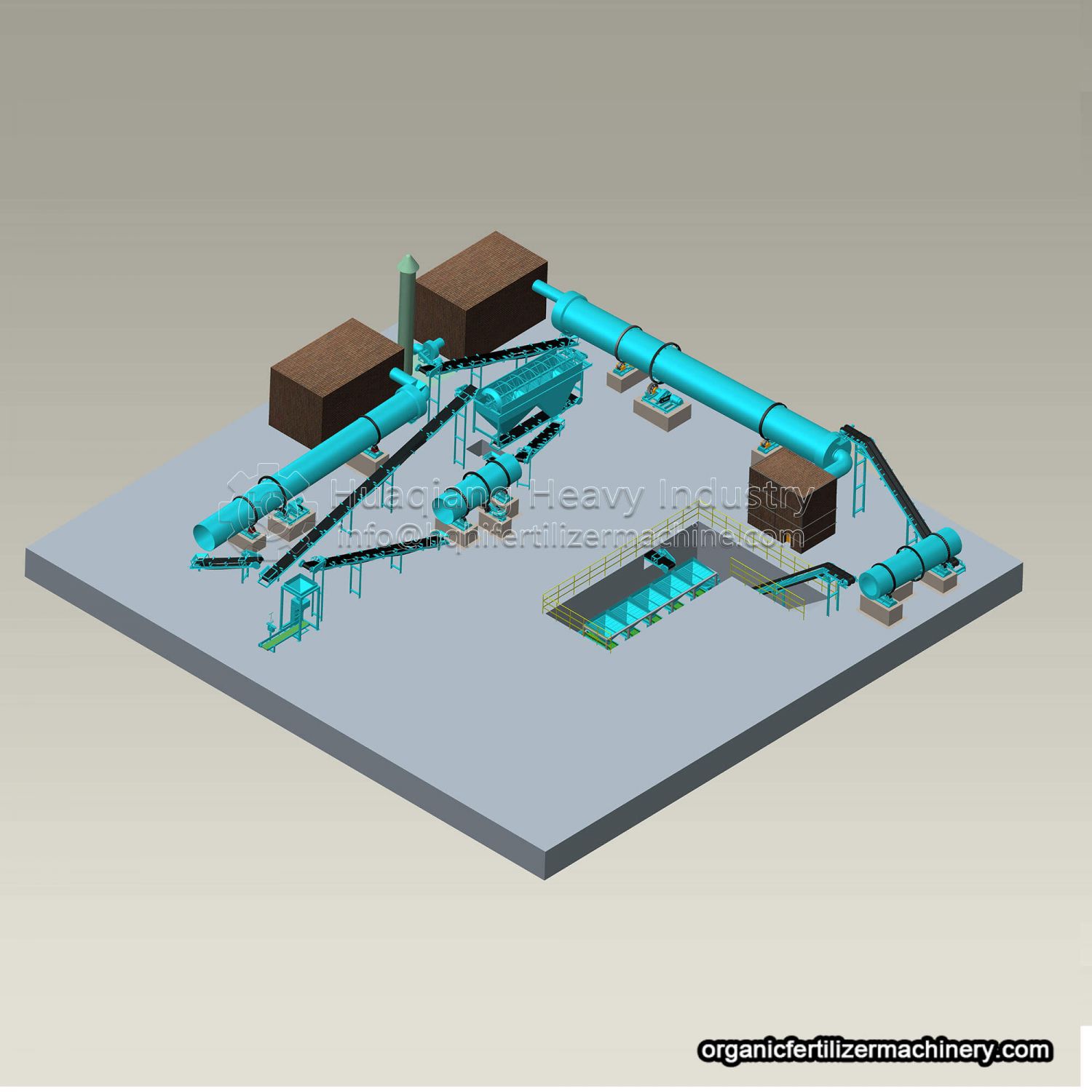

The organic fertilizer production line uses modern microbial technology, mainly livestock and poultry excrement, and bran, peanut shell powder, crop straw and other auxiliary materials as carriers. The bacteria and livestock and poultry excrement are fully mixed by mixing method, so that the microbial strains are connected to the livestock and poultry excrement, including dehydrator, fermentation turner, semi-wet material crusher, horizontal mixer, disc granulator, dryer, cooler, drum screening machine, film coating machine The bio-organic fertilizer produced by packaging equipment, belt conveyor and other equipment after a series of harmless treatment such as rapid heating, fermentation, decomposition and deodorization.

How to ferment and granulate manure with organic fertilizer crusher?

Fermentation and processing of organic fertilizer by cow manure organic fertilizer production line

The use of cow dung as fertilizer in the planting process is to provide the nutrients needed for crop growth. However, when using cow dung in the planting field, it should be noted that cow dung must be decomposed in the organic fertilizer fermentation tank before being used as organic fertilizer. When it is decomposed at high temperature, it will kill the insect eggs and bacterial viruses in the cow dung. In addition, cow dung can be reused after fermentation and decomposition to avoid burning the roots due to heat.

For the production line of cow manure organic fertilizer, it is recommended to adopt aerobic fermentation treatment. It can be fermented with fermenting agent, which is better for crops. Mix cow manure with straw, sawdust, mushroom residue, etc. in an appropriate proportion (dung accounts for 80-90%, other accounts for 10-20%). 1 ton of material (about 2.5 tons of fresh material) plus 1 kg of fertilizer starter, diluted by 1 kg of fertilizer starter plus 5 kg of rice bran (or bran, corn flour and other substitutes), and then evenly scattered into the material pile. Pay attention to proper oxygen supply and pile turnover during fermentation, and control the temperature at 55-65 ℃. The moisture content of fermentation materials should be controlled at 60~65%.

The method for adjusting the moisture content of materials in the cow manure organic fertilizer production line: the moisture content of fermented cow manure and other livestock and poultry manure should be controlled at 40~65%. Moisture judgment: Grasp a handful of cow dung tightly, see the watermark but do not drip on the finger seam, and it is appropriate to disperse immediately after landing. The fermentation is slow with less water, and the ventilation is poor with more water. Therefore, we must grasp the water content. If the moisture is too high, straw, sawdust, mushroom residue, dry earth powder, etc. can be added. The method to judge whether the moisture is suitable or not: grasp a handful of materials tightly, see the watermark on the finger joint but do not drip, and disperse immediately after landing. Generally, the whole fermentation process can complete the complete deodorization of materials, fermentation maturity, insecticidal sterilization, etc. in 5-7 days.

Technical start-up temperature of cow manure production organic fertilizer production line. The startup temperature should be above 15 ℃ (it can be operated in four seasons, not affected by the season, and try to ferment indoors or in the greenhouse in winter), and the fermentation temperature should be controlled below 70-75 ℃.

Mix well and ventilate. The production of organic fertilizer by cow dung fermentation requires good (consumption) oxygen fermentation. Therefore, the oxygen supply measures should be increased during the operation process, so as to achieve uniform mixing, frequent turnover and ventilation. Otherwise, it will lead to anaerobic fermentation and odor, affecting the fertilizer effect.

Fermentation is complete. Generally, after 48 hours of cow dung accumulation, the temperature rises to 50~60 ℃, and it can reach more than 65 ℃ on the third day. Under this high temperature, it can be overturned once. Generally, there will be two times of high temperature above 65 ℃ in the fermentation process. The fermentation can be completed after two times of overturning, and the fermentation can be completed within a normal week. The material is dark brown, and the temperature begins to drop to normal temperature, indicating that the fermentation is complete.

Process introduction of small cow manure organic fertilizer production line

There are many kinds of organic fertilizer products, among which bio organic fertilizer is a relatively high-grade fertilizer. The production process of bio organic fertilizer with livestock manure is slightly different from that of other fertilizers. The purpose of this process is to protect the microbial bacteria in the process of fertilizer production. The following is a brief description of the production process of this fertilizer with various raw materials.

How to process top dressing with organic fertilizer production line

Organic fertilizer is not only an ideal base fertilizer, but also as topdressing. It is the main fertilizer variety to provide nutrients during crop growth. Attention should be paid to the following matters when organic fertilizer is used as topdressing:

Early application

Make reasonable distribution proportion of base fertilizer and topdressing fertilizer