Advantages of chicken manure in composting and fermenting fertilizer using organic fertilizer production line

Nowadays, organic fertilizer has been loved by cash crop growers all over the country, and plays an indispensable role. Bioorganic fertilizer contains a large amount of organic matter, which is an important source of organic matter in soil. It can improve soil, improve soil fertility, turn lean soil into fertile soil, and turn bad soil into good soil. Because soil organic matter forms humus through the action of microorganism and physical chemistry, it can promote the formation of soil water-stable aggregate structure, make cohesive soil loose and easy to cultivate, and sandy soil become structured.

Taking livestock and poultry manure as an example, the annual output of 5000 tons of granular organic fertilizer equipment investment, production cost and benefit analysis.

Input cost of organic fertilizer production line:

Calculation of production cost of organic fertilizer (organic fertilizer per ton of product):

The total production cost per ton of granular pure organic fertilizer (with nutrient content of more than 9% and organic matter of about 75%) is about 180.0 yuan/ton.

Analysis of organic fertilizer sales income

The production cost per ton of pure organic fertilizer produced by fermentation mode is about 180.0 yuan/ton. It is adjusted according to the national organic fertilizer standard, plus the warehousing cost of packaging bags, etc. of 50 yuan/t. It is sold at the current market price of 600 yuan per ton. The gross profit per ton is 270 yuan/ton. The net profit is calculated at 50 yuan, excluding the intermediary and transportation fees. The annual sales of 5000 tons * 270 yuan/ton can earn 1.35 million yuan.

The above data are for reference only, mainly because the prices of facilities and equipment produced by different factories are different, and the costs of plant construction and labor costs are different in different places. In addition, the above is the investment required for one production of organic fertilizer. If multiple organic fertilizer production lines are built, they can be calculated by superposition, but some equipment and facilities can be shared. Therefore, the more production lines, the lower the average investment.

There are many kinds of raw materials for organic fertilizer processing. We will use organic fertilizer mixing machine when processing. The different materials mixed by the mixer and the nutrient are even, so they can be suitable for the granulation of the organic fertilizer granulator machine.

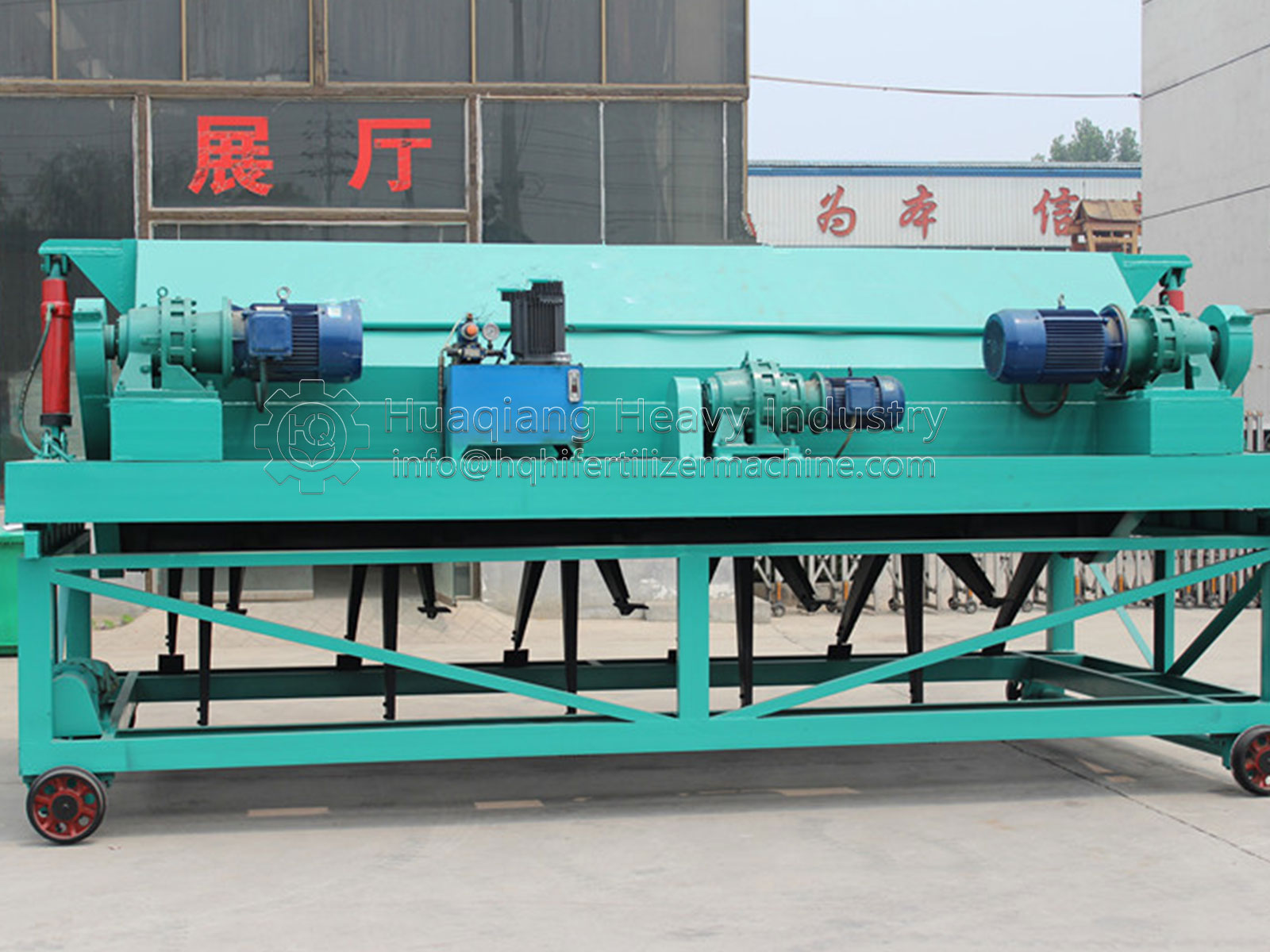

Economical and practical compost turning machine

Working Principle

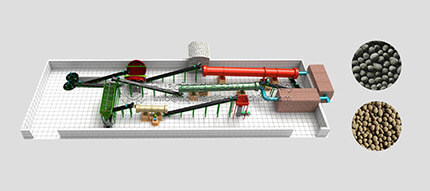

Small-scale organic fertilizer production line is mainly used for livestock manure organic fertilizer processing production line project. It is characterized by low overall investment price, low cost and low technical requirements, which is suitable for large-scale planting and breeding enterprises and small fertilizer plants.

Finally, according to the desired form of organic fertilizer, it can be divided into powder organic fertilizer and granular organic fertilizer. Different forms of fertilizer require different production line equipment. Because the configuration, specification and required equipment of organic fertilizer production line are different, the price will also affect the quotation.

The production of powdery organic fertilizer is based on the fine crushing treatment after the fermentation of organic fertilizer. The required equipment: fermentation tipper, forklift silo, semi-wet material crusher, drum screening machine, automatic packaging scale. The price of the smallest powdered organic fertilizer production equipment is about 100000 yuan.

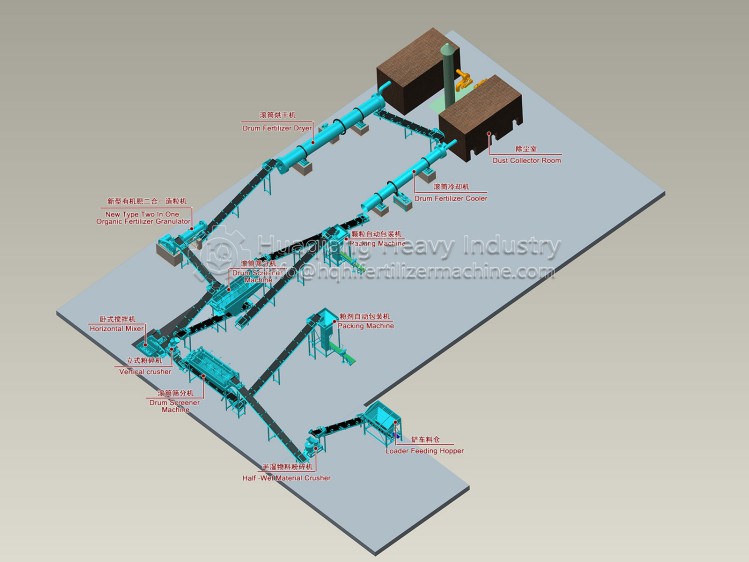

At present, the production process of granular organic fertilizer is the most complex, and it is also based on the continuous fermentation process and the wages of powdered organic fertilizer. Therefore, the equipment required is also relatively comprehensive, including fermentation tipper, forklift silo, semi-wet material crusher, horizontal mixer, stirrer granulator, rotary dryer, rotary cooler, drum screening machine, coating machine, and automatic packaging machine. Dynamic batching scale is also required in case of special process requirements. The price of the complete set of equipment with the minimum specification is about 200000 yuan.

In terms of production scale alone, the small-scale organic fertilizer processing plant takes the annual output of 5000 tons to 10000 tons as the standard, which is also the most selected production line scale for investors who are new to the industry. The complete set of equipment is composed of many kinds of equipment. Their type selection, specification and quantity directly affect the final price of the production line. That is to say, the price of the production line with the same output is not the same, even very different. Under the same output, the powdery production line is much cheaper than the granular production line, but the corresponding powdery finished organic fertilizer is not as expensive and profitable as the granular organic fertilizer. Finally, it is suggested that you should pay attention to two points: first, raw material procurement; The second is marketing. These two aspects are very important. In short, the same sentence: entrepreneurship is risky, and investment needs to be cautious.

According to different raw materials, organic composting fermentation equipment can be divided into high temperature composting and ordinary composting. High temperature composting takes plant materials with high fiber content as the main raw materials, and generates a lot of heat through composting and fermentation under aerated conditions. The temperature of composting is very high (50-60 degrees Celsius). Therefore, it matures quickly, composts quickly and has high nutrient content. The following NPK production line manufacturers introduce how long it takes for organic fertilizer fermentation equipment to process.

1. High quality controlled release fertilizer is a special fertilizer for vegetables and fruits.

China is a large agricultural country, with an effective land planting area of more than 3.1 billion mu, and a large demand for fertilizer. With the rapid development of social economy, people’s awareness and requirements for organic and green food are gradually increasing, and the development of organic agriculture and ecological agriculture is also gradually increasing. The application of chemical fertilizer in agricultural production has led to soil hardening and degradation of agricultural product quality, resulting in low crop yield. Therefore, the State encourages the use of organic fertilizer and has issued relevant subsidies and preferential policies, which has promoted the development of the organic fertilizer industry, and also brought good development opportunities and good market prospects to the organic fertilizer industry.

The factories that set up an organic fertilizer equipment production line to process fertilizer in the countryside are generally privately built, so a small organic fertilizer equipment production line with an annual output of about 10000 tons is sufficient to meet the sales demand. The primary focus of the organic fertilizer processing is the purchase of raw materials, and the most simple and small production line of organic fertilizer is raw and auxiliary materials:

Purchase organic fertilizer processing raw materials, chicken manure, pig manure, sheep manure, cow manure. These raw materials are not expensive, and the purchase price can be cheaper.

The investment of small organic fertilizer production line is between 80000 yuan and 120000 yuan. The main equipment of the small-scale organic fertilizer equipment production line includes fermentation tipping machine, pulverizer, granulator, screening machine, automatic weighing and packaging machine, etc. This series of small organic fertilizer production line has not only high cost performance, but also high efficiency, good energy saving and simple operation for workers. Equipment for small organic fertilizer production line:

In the process of compound fertilizer granulation by rotary drum granulator, the pH of material is a main factor of fertilizer granulation, and also has an important impact on fertilizer efficiency and NPK production line.

When selecting organic fertilizer equipment, we should pay attention to the annual output, organic raw materials, compost fermentation mode, and the degree of mechanization of the compost turning machine. These are the key factors for organic fertilizer processing. In short, organic fertilizer production is a relatively complex process, but the risk is relatively small. If all aspects are mature, it can bring huge profits to the enterprise. The following describes the difference between organic fertilizer equipment and inorganic fertilizer equipment.