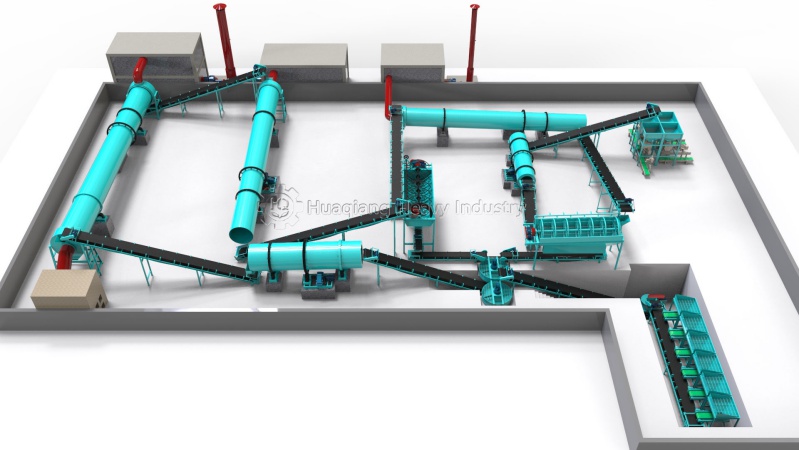

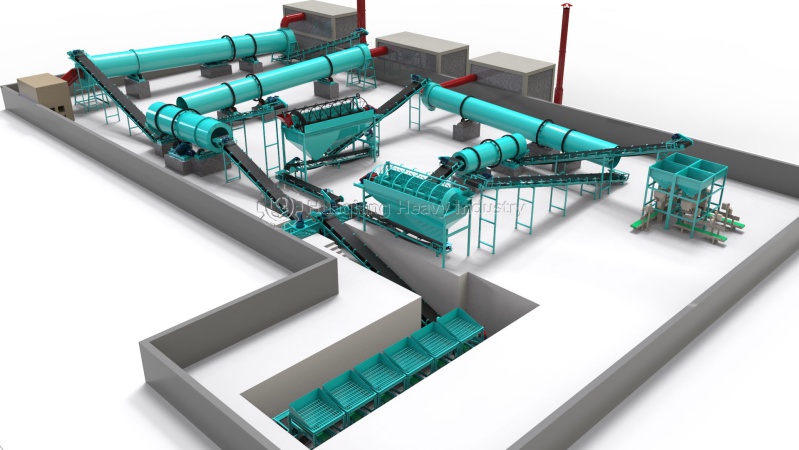

The npk production line equipment usually includes: crusher, feeder, horizontal mixer, double roller granulator, dryer, cooler, screening machine, weighing and packaging machine. Especially in the production of npk compound fertilizers and organic fertilizers, pulverizers are essential production equipment.

.jpg)

1. The maintenance of pulverizer equipment needs to focus on the following aspects

1) Check whether the power supply, power socket, plug, and power cord are deoxygenated and broken.

2) Check whether the bearing is well lubricated, and use lubricating oil regularly for maintenance.

3) Check whether all fasteners are fastened, and deal with them in time if they are loose.

4) Check whether the transmission belt is installed correctly and in good condition. If the belt is damaged, it should be replaced in time. When there is oil on the belt or sheave, wipe it with a clean rag in time.

5) Check whether there are materials or other sundries in the damaged cavity, and remove them if necessary.

6) Check the sealing condition of the fan to prevent the sand from severely abrading the fan, causing the rivet heads of the impeller and hub to fall off, and fatigue cracks in the rivet holes.

Second, the following points should be paid attention to when inspecting and maintaining equipment

1) Bearing lubrication replacement: After the crusher works for 300 hours, the bearing should be cleaned. If the bearing is lubricated by engine oil, add new engine oil to fill 1/3 of the bearing seat gap, not more than half. Before operation, just tighten a small amount of regular oil cup cover. When the crusher bearing is seriously worn or damaged, it should be replaced in time, and attention should be paid to strengthening lubrication; adjust the paper pad at the bearing cover.

2) Replacement of claws and hammers: Among the crushing parts, the crushing claws and hammers are the vulnerable parts of the straw crusher, and they are also the main components that affect the crushing quality and productivity. The broken claws and hammers should be replaced in time after they are worn out. When replacing the claws of the claw crusher, the disc should be pulled out first. Before pulling it out, we need to remove the screws on it, and then pull it out.

.jpg)