The 100,000-ton NPK compound fertilizer production line meets the needs of most customers. It is a large-capacity production line. We choose the rotary drum granulator as the main fertilizer making equipment, which is an ideal equipment for large-scale production of high- and low-concentration compound fertilizers. The double roller granulator can be used in small npk production line granulator.

The npk manufacturing process, the compound fertilizer production system has low requirements on formula. The steam with a pressure of 4-6kpa is passed into the drum granulator, mixed with powdered phosphorus, potassium or other nitrogen-containing fertilizers and conditioners, and further granulated. The steam melts the surface of the N, allowing the N to combine with other raw materials. This compound fertilizer production line is especially suitable for high nitrogen compound fertilizer. Various fertilizers can be produced in concentrations ranging from 25% to 48%. Since the moisture content of the material is 3-5% during granulation, the drying capacity is increased by 20%-40%, which greatly increases the fertilizer output and reduces the consumption.

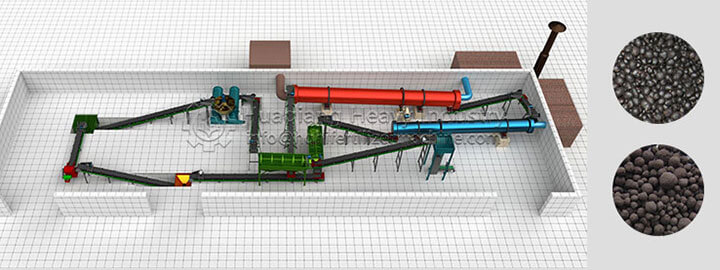

100,000 tons of npk production line process The entire compound fertilizer production process: raw material batching, raw material mixing, granulation process, drying process, cooling process, screening process, coating process, packaging process.

Raw material mixing and granulation:

Mix the raw materials evenly to increase the nutrient content of the granular fertilizer. After mixing evenly, the raw materials are transported to the drum granulator for granulation, and steam and gaseous ammonia are introduced, or orthophosphoric acid, ammonium phosphate slurry, nitrogen solution, and calcium carbonate slurry are added, and a series of chemical reactions occur in the drum . A small amount of water can be added throughout the production process. The drum rotates, and the raw materials are condensed into fertilizer granules under specific temperature and humidity. This is the whole NPK fertilizer granulation process.

Drying and cooling of fertilizer granules:

The ammonia phosphorus potassium fertilizer is sent to the tumble dryer to dry out the moisture in the fertilizer granules and improve the strength of the fertilizer. After drying, due to the high temperature, the fertilizer is easy to agglomerate, so the NPK granular fertilizer needs to be cooled for storage and transportation. We chose the drum cooler because of its high efficiency and high output per hour.

.jpg)

.jpg)

.jpg)