In the fascinating world of agricultural technology, the NPK fertilizer manufacturing process stands as a testament to human ingenuity. At the heart of this sophisticated operation lies the remarkable NPK fertilizer granulator machine, engineering marvel that transforms raw materials into precisely formulated plant nutrition. The complete NPK manufacturing process represents a seamless integration of mechanical precision and chemical expertise, efficiently converting diverse raw materials into uniform, nutrient-rich granules. This intricate system not only exemplifies manufacturing excellence but also plays a crucial role in global food security, enabling farmers worldwide to maximize crop yields while minimizing environmental impact through precisely calibrated nutrient delivery.

.jpg)

A comprehensive look at the fascinating process and equipment behind modern fertilizer production

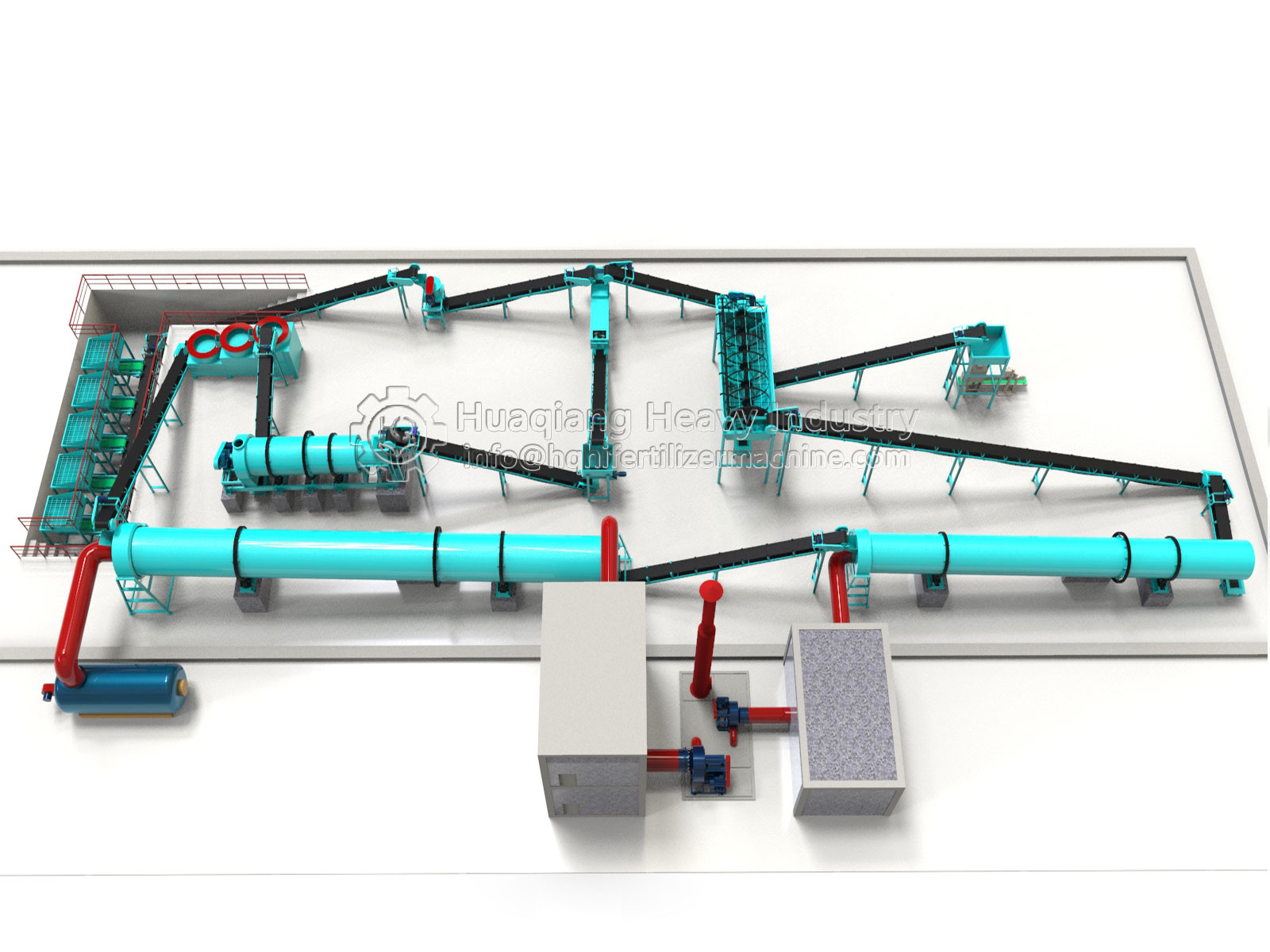

The Complete NPK Fertilizer Production Line

The production of high-quality NPK fertilizer requires a sophisticated, integrated system of specialized machinery. Each piece of equipment plays a vital role in transforming raw materials into the uniform, nutrient-rich pellets that help feed our world.

1. Automatic Batching Machine

Precisely measures and combines raw materials according to specific formulas

2. Belt Conveyor

Transports materials efficiently between different stages of production

3. Mixer

Thoroughly blends components into a homogeneous mixture

4. Crusher

Breaks down any clumps for consistent texture

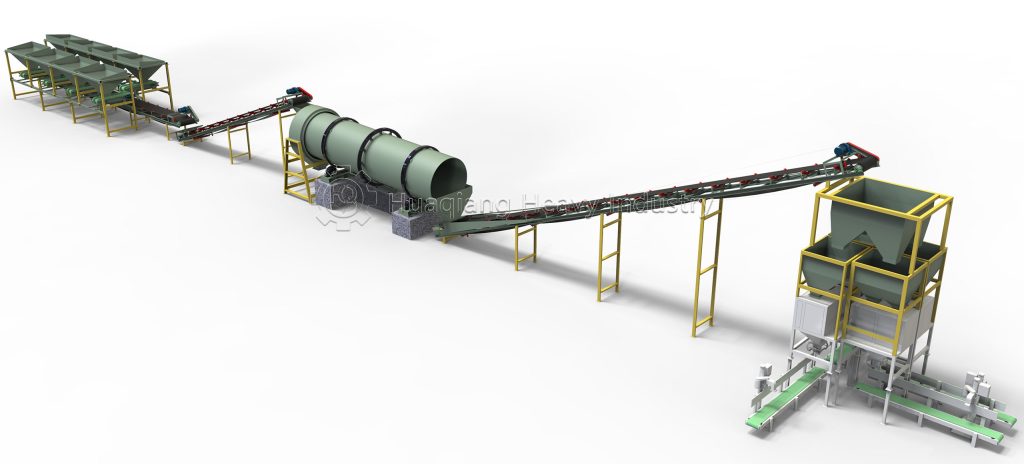

5. Rotary Drum Granulator

The heart of the operation – forms the mixture into uniform granules

6. Dryer

Reduces moisture content to appropriate levels

7. Cooler

Brings product temperature down for further processing

8. Screening Machine

Separates properly sized granules from undersize and oversize material

9. Coating Machine

Applies protective coatings to prevent caking and improve quality

10. Automatic Packing Machine

Weights and packages the finished product for distribution

Remarkable Advantages of Modern NPK Production

The NPK fertilizer manufacturing process offers exceptional versatility, adapting to various raw materials beyond just compound fertilizers. This flexible system can process materials from pharmaceuticals, chemicals, and animal feed industries with equal efficiency.

At the core of the NPK manufacturing process lies the aggregate method, centered around the sophisticated NPK fertilizer granulator machine. This approach, refined through years of research and development, allows producers to customize formulas based on regional soil conditions and crop requirements.

The benefits of this tailored approach are substantial:

· Enhanced Agricultural Quality: Custom-formulated fertilizers improve crop health and yield

· Increased Efficiency: Optimized nutrient ratios maximize fertilizer utilization

· Environmental Benefits: Reduced waste and more precise application minimize ecological impact

· Economic Advantages: Farmers achieve better results with fewer resources

The modern NPK fertilizer manufacturing process represents a perfect marriage of mechanical innovation and agricultural science. By continuously refining the NPK manufacturing process, equipment manufacturers contribute significantly to sustainable agriculture practices worldwide.