Organic fertilizer can make microorganisms in soil multiply, especially many beneficial microorganisms, such as nitrogen fixing bacteria, ammonifying bacteria, cellulose decomposing bacteria, etc. These beneficial microorganisms can decompose organic matter in soil, increase soil aggregate structure and improve soil composition.

Microbes propagate rapidly in the soil, they are like an invisible net, very complex. After the death of microbial cells, many small pipes will be left in the soil, which not only increases the permeability of the soil, but also makes the soil soft and soft, so that nutrients and water are not easy to lose, increasing the soil’s water storage and fertilizer storage capacity, and avoiding and eliminating soil hardening.

The beneficial microorganisms in organic fertilizer can also inhibit the reproduction of harmful bacteria, so less chemicals can be used. If it is applied continuously for many years, it can effectively inhibit soil pests and save manpower, financial resources and pollution.

At the same time, organic fertilizer contains various active enzymes secreted by animal digestive tract and various enzymes produced by microorganisms. After these substances are applied to the soil, the enzyme activity of the soil can be greatly improved. Long term sustainable use of organic fertilizer can improve soil quality. If the soil quality is fundamentally improved, there is no need to worry that high-quality fruits will not be planted.

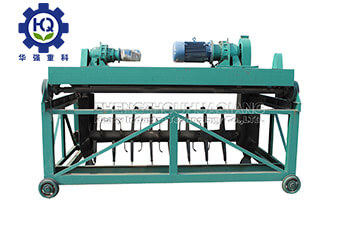

Organic fertilizer granulation equipment: granulation of mixed fertilizer is an important process of dry powder granulation process. It is not only related to the internal and external quality of products, but also to the size of output and cost. In addition to the physical and chemical properties of materials, the granulation process is closely related to the form and mechanical properties of granulation equipment. The main types of granulation equipment include disk granulator, drum granulator, double shaft granulator, extrusion granulator and spray granulator dryer.