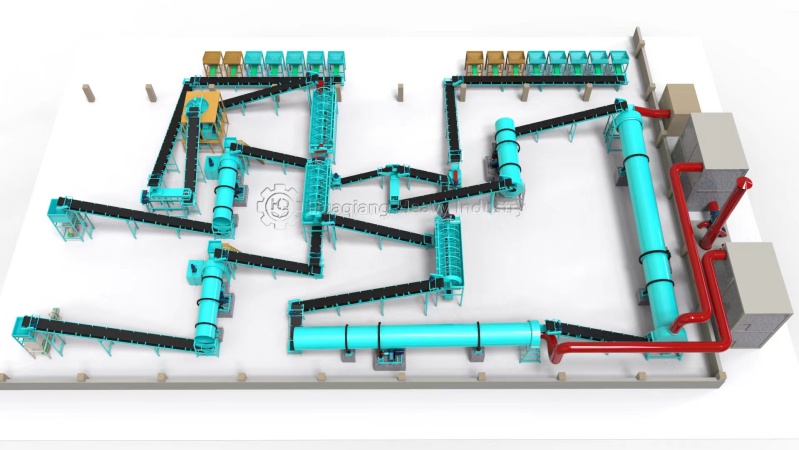

The organic fertilizer production line is an equipment for mass production of bio organic fertilizers, which plays a very important role in the development of agriculture. The organic fertilizer equipment ferments crop waste and livestock waste, such as straw, corn cob, distiller’s grains, chicken manure, pig manure, and other manure containing organic substances, to produce organic fertilizer containing a large number of microbial strains. The microbial strains in the finished organic fertilizer can improve the soil structure, increase the content of organic matter in the soil, and use chemical fertilizers and compound fertilizers to greatly increase crop yield. After a certain process flow of fertilizer production line, high-quality organic fertilizer can be processed. Below is a complete set of production process flow of organic fertilizer production line:

1. The raw materials, auxiliary materials, and fermentation agents are pre mixed evenly through the equipment in proportion, with a moisture content of about 60. They are transported by conveyor belts and distributed to the fermentation tank through shuttle belt distribution machines.

2. In order to fully ferment the materials in the fermentation tank, a chain plate tipping machine is used to flip and shift the materials. At the same time, the aeration system is used to aerate the bottom of the tank, allowing the materials to undergo aerobic fermentation.

3. The fermentation of the material is basically completed in the fermentation tank for about 7 to 10 days. Under the flipping displacement of the flipping machine, the material is flipped to the discharge end, and then transported to the aging tank through the pool changing discharge machine, discharge belt conveyor, and shuttle type distribution machine for secondary fermentation during aging, so that the material matures thoroughly.

4. The decomposed materials are transported to the granulation workshop through conveyor belts, and are screened and processed by drum screening machines and vertical crushers to remove large blocks of materials;

5. The screened materials and other inorganic nutrients are transported proportionally to a dual shaft paddle mixer using a batching belt scale and mixed evenly. Uniformly mixed materials can be packaged as powder products, and can also be granulated by adjusting the moisture content to around 40.

6. Materials with a moisture content of about 40% are produced into columnar semi-finished products through a organic fertilizer granulator, which are then shaped into spherical granular semi-finished products by a shaping machine. They are transported by a conveyor belt to a tubular dryer for low-temperature drying, and then screened and cooled by a cooling screening machine to reduce the moisture content to between 15 and 30. Packaging can also be carried out after further coating treatment as needed;

7. The finished particles are transported to the packaging workshop through bucket elevators and finished product conveyor belts, and are packaged using automatic measuring packaging scales and manually stacked.

The organic fertilizer production line not only solves the environmental pollution caused by the storage of agricultural breeding wastes, but also improves the soil structure and increases crop yield. Recycling resources plays a crucial role in promoting sustainable development in agriculture.

.jpg)