In the process of organic fertilizer production, users choose the suitable production equipment and machine model according to the output of their own factory. The quality of organic fertilizer fermentation is guaranteed by the compost turning machine, and the fermented material is suitable for the deep processing of organic fertilizer granulator machine.

Posts in the fertilizer production process category:

Manure production by manure composting machine

There are many kinds of fermentation methods in fermentation equipment, mainly including compost turning machine and fermentation tank. We focus on the production of organic fertilizer compost turner equipment, accumulated many years of industry experience, serving many customers from the idea to realize the production of organic fertilizer process. As an organic fertilizer equipment manufacturer, our experience has helped our customers avoid detours and accelerate the realization of profits.

Precautions for using dryer in NPK fertilizer production line

Whether it is organic fertilizer processed by the compost turning machine or NPK fertilizer, dryers are often used in the production and processing of fertilizer plants.

Precautions for installation of NPK production line of dryer

Screening and Beating of Drum Screen in Fertilizer Production Line

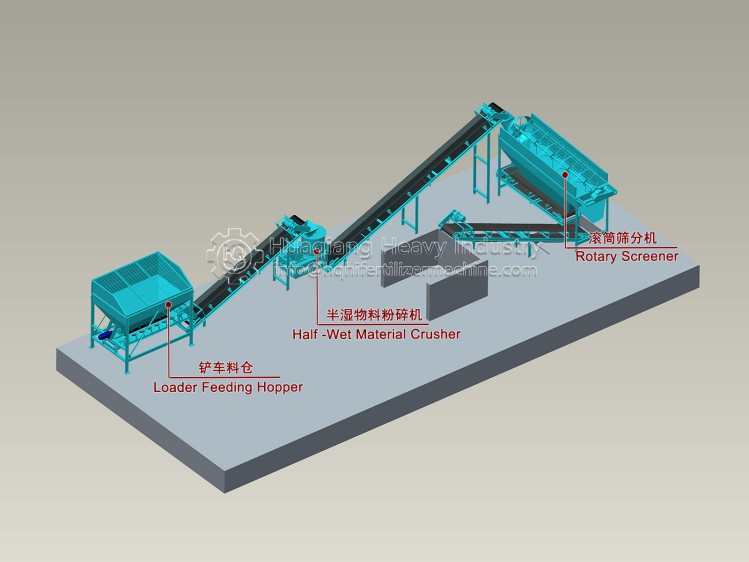

Fertilizer equipment drum screener machine is divided into ordinary screening machine, automatic beating device screening machine. According to the general screening equipment, we specially designed the drum screening machine, which has small screening resistance, small power and standard thickness steel plate. The designed dust cover can remove the powder dust, improve the working environment and protect the environment. This kind of fertilizer equipment after-sale maintenance is simple and convenient, only need to replace the screen.

Reasons for using livestock manure to produce organic fertilizer in agriculture

With the continuous popularization of organic fertilizer, more and more people begin to use organic fertilizer for production and planting. There are many raw materials for producing organic fertilizer, but many double roller granulator use manure to produce organic fertilizer.

The green, ecological and sustainable development of the circular economy of the double roller granulator not only ensures food safety, but also solves the environmental pollution caused by feces. Moisture control of organic fertilizer fermentation: 65% of organic fertilizer fermentation moisture, how to judge the moisture content? Grasp a handful of materials with your hand, you can see the watermark on your finger, but it will not drip, it will fall to the ground and spread. High water content will lead to poor ventilation, slow temperature rise and unpleasant smell. High water content can be obtained by adding straw, sawdust and mushroom residue. When the water content is too low, the fermentation is slow. When the water content is too low, the manure or water separated by the solid-liquid separator can be used to ensure the water content.

Animal manure processing equipment can process animal manure into organic fertilizer in a short time, so it is also called organic fertilizer production equipment. When the equipment system is working, the feces of livestock and ingredients are sent to the mixing mixer according to the specified proportion for mixing and mixing to make it uniform. The mixture is further mixed by the screw conveyor and sent to the host pressurized mixer. The temperature of the mixture in the machine is raised by the pressure friction of the pressurized mixer, killing or inhibiting low-temperature bacteria, killing ascaris eggs and harmful bacteria, and then providing appropriate air and water, Create suitable conditions for thermophilic bacteria fermentation, complete the rapid fermentation, then crush and loosen it through a grinder, and finally send it to the storage yard for stacking to become organic fertilizer.

Application of Organic Fertilizer Crusher in Life

The organic fertilizer crusher can be divided into three parts:

- Frame part: the normal operation of all machines can not be separated from a solid frame. The frame is welded by high-quality carbon steel plate and channel steel, and has passed strict product certification and specific process requirements, so as to achieve the purpose of using the machine;

- Rotor crushing part: the rotor structure of the machine is novel and the design is reasonable. The crushing effect is twice that of other products. The materials enter the crushing chamber from the feed inlet and are continuously crushed by double knives to meet the granulation requirements. There are thrusters and scrapers inside, and its materials will not stick to the wall.

- Transmission connection part: the machine is driven by flexible belt. The belt pulley and belt are driven by the motor and directly transmitted to the main shaft, which makes the main shaft rotate at a high speed to achieve the crushing effect.

As an important part of the organic fertilizer production line, the organic fertilizer crusher also has its own machine. The appearance of the pulverizer greatly reduces the crushing of manpower, and greatly improves the efficiency. During driving, the rotating knife loaded under the machine is used to stir, fluff and flip the chicken manure organic fertilizer raw materials. Leave a new strip pile on the road where the vehicle passes.

The appearance of the grinder has really made a great contribution to the organic fertilizer production line. The technology of the grinder integrates the crushing function of the material after fermentation. After the dehydration of materials, the grinder can effectively break the blocks formed by fertilizer in the fermentation process, which not only saves the work of the grinder, reduces the cost, but also improves the crushing efficiency, fundamentally solving the drawbacks of the grinder.

It meets the functional mechanism and process requirements of microbial fermentation and feces storage, and can effectively mix the viscous livestock manure with microbial agents and straw powder. In the loose material state, the deodorization of chicken manure takes about three hours, and the fermentation temperature can be controlled at about 60 ℃ for 4 days. The fertilizer can be formed in 7 days, and the number of beneficial microorganisms in the soil shall not be less than 30 billion/g. It is not only much faster than the traditional fermentation method, but also effectively prevents the production of hydrogen sulfide, ammonia and other harmful gases in the fermentation process, which meets the environmental requirements and can produce high-quality organic fertilizer.

Ecological technological process and application effect of pig manure organic fertilizer production line

Pig dung and chicken dung are one of the most notorious stinky dung in the breeding industry. Pig manure should be a good farmyard manure, and a high-quality organic fertilizer resource for soil improvement. However, if fresh pig manure is applied directly, it will inevitably cause crop root injury, disease, grass damage and other negative effects. According to statistics, about 1000 pigs are sold annually, and about 1.2t of fresh pig manure is produced every day. If the natural composting and fermentation process is used in the past, there are several disadvantages: first, the composting time is long (4-6 months), and the effect is poor; Second, long-term stacking not only occupies the site, but also causes pollution to the surrounding environment. Third, the natural composted fermentation faeces are rotten, wet and stinky, which is difficult to transport and directly apply.

The pig manure harmless treatment organic fertilizer production line technology is analyzed by taking the manure treatment of pig farms with a breeding scale of about 1000 pigs as an example. The microbial fermentation strain used in this project is a highly effective composite microbial agent that can rapidly decompose livestock manure, crop straw sludge, agricultural by-product processing organic waste, etc., and has the following significant characteristics:

A Fast maturing organic solid stacking material, suitable for a variety of different composting substrates and different organic fertilizer dumping equipment;

B The content of effective living bacteria is more than 5 billion/g, and the addition amount is small and the cost is low. It only costs 8 yuan per ton;

C temperature rises quickly. When the ambient temperature is 0-5C, the composting temperature can rise to 55-70 “C within 48-72 hours;

D The composting cycle is short (7-10 days), which can save a lot of site and production costs:

E can quickly and effectively eliminate the peculiar smell in materials;

F has less nutrient loss, and the total nitrogen loss rate is less than 1%, which can effectively maintain the effective nutrient of compost. After fertilizer application, it can increase the number of microbial flora, improve the physical and chemical properties of soil, adjust the soil pH value, and has significant fertilizer effect;

G The high temperature of compost lasts for a long time, which can kill the bacteria and eggs in the raw materials of compost, make the compost reach the harmless standard in a short time, and become an efficient commercial organic fertilizer meeting the requirements of green food production.

H The amount of organic fertilizer produced by fermenting pig manure with BM strain is small, which can be used as base fertilizer: 80-150 kg/mu for cash crops such as vegetables, 80-100 kg/mu for grain, 80-100 kg/mu for tea trees, 1-3 kg/tree for fruit trees, and 0.5-1 kg/m2 for lawn.

Efficient fermentation of chicken manure by organic fertilizer composting equipment

Chicken manure compost turning machine can promote the rapid decomposing of livestock and poultry manure and other inorganic wastes. The equipment adopts continuous aerobic fermentation process to rapidly decompose, dewater, sterilize and deodorize the inorganic wastes to achieve harmlessness and resource utilization. And the goal of reduction and disposal, low power consumption and stable product quality.

Introduction of chicken manure fermentation turner

Features of chicken manure fermentation turner machine

Semi wet material organic fertilizer crusher can produce those fertilizers

The comprehensive promotion of the enterprise has changed our development direction and made our future more clear. We will strive for better development in the future, promote new production technologies, share new discoveries and breakthroughs in the market, and seek development. The semi wet material organic fertilizer crusher with new technology transformation is looking forward to your arrival. The development demand of the industry is such a high-quality product. Whether it is the quality of equipment or technology, the after-sales service is better in the industry. We conscientiously and responsibly manufacture new equipment, take charge of our own products, and take charge of the safety production of users. We start from the details and carefully create excellent products in the industry.

The semi wet material organic fertilizer crusher uses a high alloy wear-resistant hammer. The forging is particularly strong and wear-resistant, which is more solid and wear-resistant than the ordinary hammer, and improves the service life of the hammer. The semi wet material crusher adopts two-way clearance adjustment technology. If the hammer blade is worn, it does not need to be repaired, and it can continue to use the location of the moving hammer. The material particle size can be controlled by adjusting the gap between the hammer and the gasket. The semi wet material crusher is high-tech and requires only one person to operate, which is safe, reliable and easy to maintain.

At present, this new type of organic fertilizer crusher is applicable to the production of organic fertilizer, bio organic fertilizer, compound fertilizer and other raw materials. In the process of grinding, high-strength wear-resistant carbide chains, plates and vertical heads with synchronous rotating speed are used. The feed inlet of the crusher is reasonably designed, the crushed materials are uniform, and the raw materials with large moisture content are not easy to stick to the wall. The crusher is easy to clean. The grinder is suitable for materials with moisture content of 20% and 50%. Its crushing effect is good, and it is the equipment for fermentation raw materials.

How to Solve Dust Pollution in Organic Fertilizer and NPK Fertilizer Production

Because of the characteristics of materials, a lot of dust will be produced in fertilizer production, which will pollute the environment. In order to avoid this problem, dust removal devices should be set up in the design of organic fertilizer manufacturing process and NPK fertilizer production project to solve the problem of dust emission.

Dust Problem in Organic Fertilizer Production Line

In the organic fertilizer production line, when the moisture content of raw materials is low, they are often crushed and uneven solids. When the raw materials are transported to the equipment, if they are transported in the open air, there is no effective sealing measures, so the dust concentration in the air of the organic fertilizer manufacturing site will be too high. In addition, most small and medium-sized enterprises lack effective treatment means when discharging exhaust gas, which leads to the emission of exhaust gas not up to the standard and dust pollution.

Dust Problem in NPK Fertilizer Production Process

Take NPK fertilizer production project as an example, because the raw material of NPK fertilizer is brittle, it is easy to form small particle dust. When the dust is disturbed by airflow, it is easy to fly. Because of the low water content of NPK fertilizer, the dust is easy to absorb and adhere to the equipment. Therefore, when grading by using the screening device, the dust can easily block the sieve holes of the screen, thereby affecting the grading effect and even damaging the screen. As a result, the screen must be frequently replaced, on the one hand, the production cost is increased, on the one hand, to improve production costs, on the other hand to reduce production efficiency.

To solve the problem of dust pollution in the fertilizer manufacturing process, it is necessary to set up a dust collector room and dust collector equipment in the process of fertilizer production. Tianci Fertilizer Machine Manufacturer have designed a special cyclone dust collector to remove dust from the organic fertilizer manufacturing process. And in the construction of fertilizer plant, dust collector room is more suitable for large NPK fertilizer production line, we can help customers build dust collector room.