Plant ash is used to manufacture fertilizer processing equipment. The residual ash from the burning of plant stems and leaves is called plant ash. In rural areas, wheat straw, soybean straw, corn straw, rice straw, tree branches, fallen leaves, and other fuels are commonly used. Therefore, plant ash is an important fertilizer resource in rural areas. Grass ash contains various ash elements in plants, such as phosphorus, potassium, calcium, magnesium, and various trace elements. Among them, potassium and calcium are abundant and are generally regarded as potassium fertilizers..jpg)

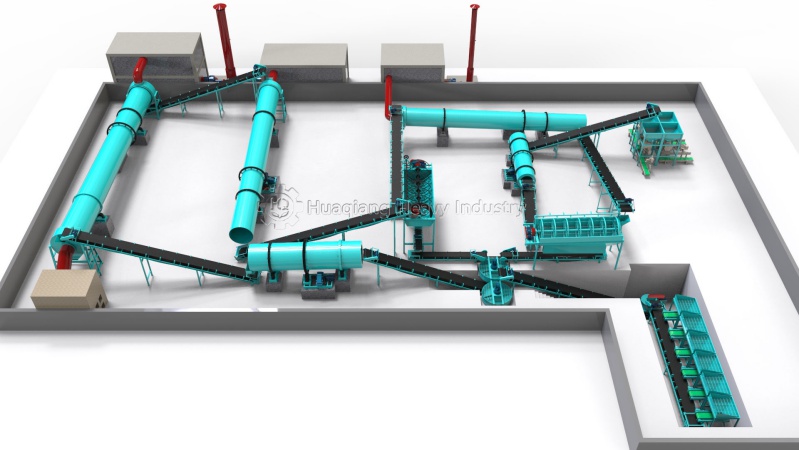

The process of compound fertilizer production equipment consists of multiple processes: raw material measurement, raw material crushing, granulation, drying, cooling, screening, coating, and packaging. The production line has always adhered to the principles of “liquidity, safety, operability, and aesthetics” in the design, so that the whole production line can achieve electromechanical integration, and it will be quite advanced in the future for a certain period of time. At the same time, we can also adjust the process flow according to specific circumstances and requirements.

The compound fertilizer production equipment is completed by a close combination of multiple processes. Each process has strict indicator control, and none is indispensable. Firstly, technical personnel develop corresponding fertilizer production formulas based on market needs or customer needs, combined with the market situation of raw materials, and refine them into the input amount of raw materials.

Circular economy is the current trend of environmental protection and sustainable development in China. It is an advanced development model that can resolve the long-standing sharp conflict between environment and development. Building a circular economy is an inevitable choice and important guarantee for implementing sustainable development strategies. And organic fertilizer equipment has a long way to go to completely solve the source of pollution.

.jpg)