Adhering to the principle of organic fertilizer as the main and inorganic fertilizer as the auxiliary is the principle of fertilization in agricultural production. Only by increasing the input of organic fertilizer, can we solve the problem of soil hardening, promote the continuous improvement of soil fertility, and effectively solve the pollution of soil and environment caused by chemical fertilizer residues.

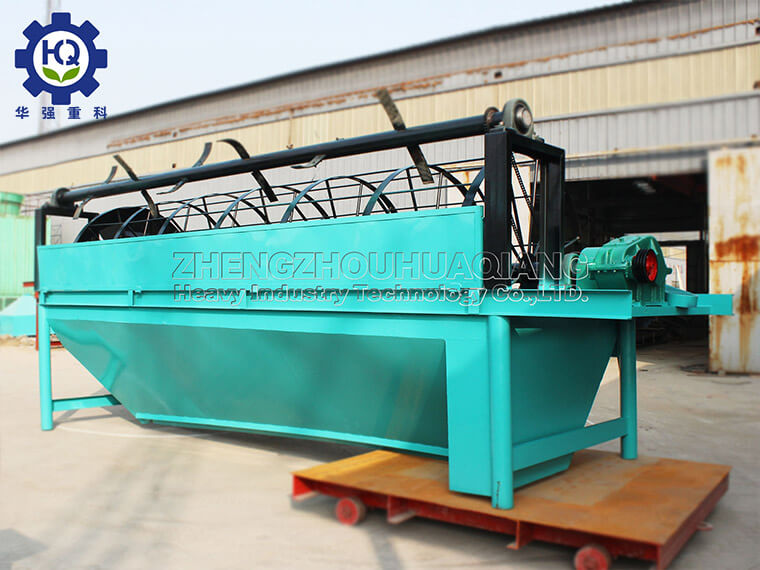

It is the mainstream to vigorously develop circular economy, promote cleaner production, and build a resource-saving and environment-friendly society. The implementation of cleaner production, organic fertilizer manufacturing process, feces depth treatment, waste into treasure. Fertilizer granulator can produce high-quality fertilizer, reduce environmental pollution caused by feces, reduce production costs, improve economic benefits of organic fertilizer equipment, and make agriculture go on the road of sustainable development..jpg)

Seeing this, you will think that the development of organic fertilizer processing equipment is smooth sailing. In fact, it is not all. There are certain risks in any investment. The same is true for organic fertilizer equipment, which is mainly affected by the local market, itself, environment and other factors.

However, the investment in organic fertilizer manufacturing process is not a few now. The investment of organic fertilizer equipment is small, the income is fast, and there are not too many advers.

.jpg)

.jpg)

.jpg)

.jpg)