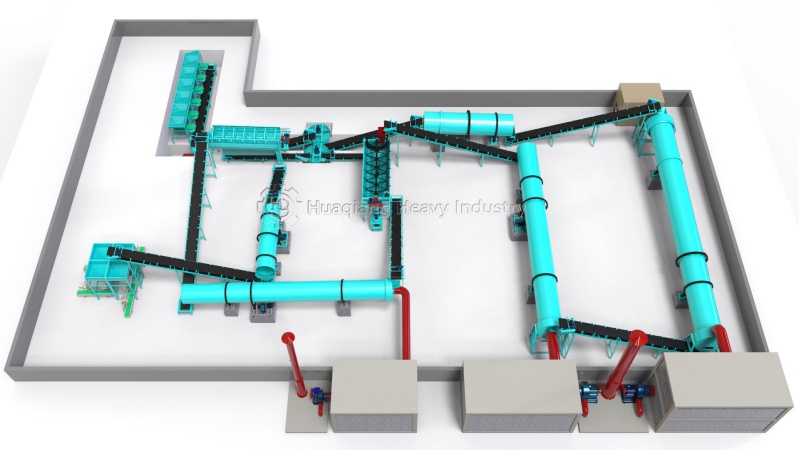

The production process of organic fertilizer equipment is mainly that the previously fermented organic fertilizer raw materials are crushed and then screened, and then the raw materials of the binder and other ingredients to be compatible are measured, batched and mixed in an automatic batching mixing system according to the proportioning requirements. (Or after further drying to produce powdered organic fertilizer), the fully mixed material is fed into the granulator uniformly and continuously by the belt conveyor for granulation.

Common organic fertilizer granulation processes are: drum granulator, disc granulator, high tower granulator, and organic fertilizer granulation mainly adopts double roller press granulator, rotary drum granulator, disc granulator , etc.

The double roller press granulator integrates the powder extrusion molding, crushing, finished product screening and other processes into one, with a compact structure and convenient operation. The powder is continuously and uniformly added to the top of the two rollers from the hopper. Under the continuous rotation of the extrusion roller, the powder is bitten between the two rollers and extruded into a sheet, and then falls off under the action of centrifugal action and the sheet’s own gravity. The shaping wheel with toothed claws is divided into particles after being hit, and then enters the separating screen. The powder under the sieve is sent back to the return material, and the granules on the sieve are rolled by the drum to grind off the acute angle of the particles, and flow out from the discharge port on the sieve bucket into the packaging.

The roller extrusion granulator has the following advantages: 1. Circular operation to achieve continuous production and high-yield finished products; 2. The material is forced to be compressed and shaped by mechanical pressure without any additives, thus ensuring the product’s quality purity; 3. The particle strength can be adjusted, and the strength of the finished product can be controlled by adjusting the pressure of the drum; 4. The extrusion granulator is suitable for a variety of raw materials, and the particle strength can be freely adjusted according to different materials; 5. Compact structure, easy maintenance, simple operation, short process flow, low energy consumption, high efficiency and low failure rate.

.jpg)

.jpg)