Cow manure itself is a good source of organic fertilizer. In addition to being rich in trace elements such as organic matter, nitrogen, phosphorus, and potassium, it also contains various biological enzymes and microorganisms. After being made into fertilizer, cow manure fertilizer can play an irreplaceable role in improving soil organic matter and fertility, improving soil structure, improving soil physical and chemical environment, and microbial environment.

Equipment required for processing cow manure into granular organic fertilizer

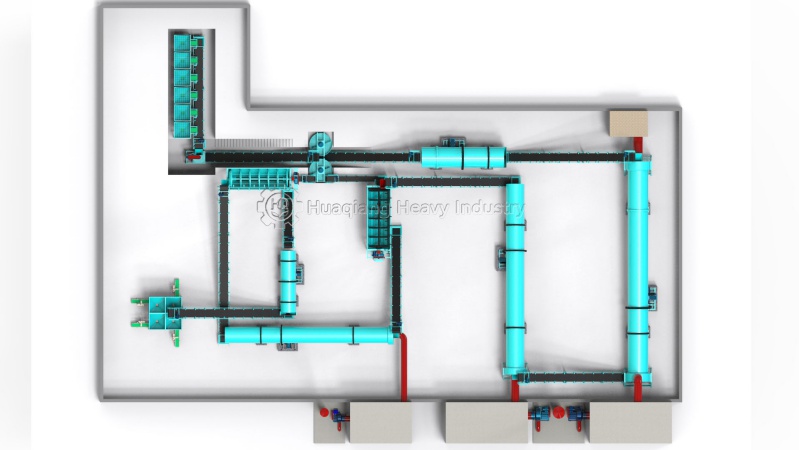

The equipment used in the production of cow manure granular organic fertilizer includes: fermentation flipping machine, belt conveyor, crusher, mixer, extrusion granulator or disc granulator, screening machine, mixer, and dryer.

Mixer – evenly and thoroughly stir pig manure and fermentation agent straw and other auxiliary materials;

Walking fermentation flipping machine – The fermentation flipping machine flips and ferments cow manure for aerobic fermentation

Semi wet material crusher – crushing fermented cow manure fertilizer

Disc granulator or extrusion granulator for fertilizer granulation – the screening machine screens out unqualified organic fertilizer particles and uses a crusher to crush and re granulate them.

Overall, the equipment required for treating organic fertilizers with cow manure includes: cow manure flipper, crusher, mixer, granulator, screening machine, dryer, and automatic packaging machine. The first step of fermentation treatment in the production process is the focus of the entire process. The fermentation effect determines the overall quality of cow manure organic fertilizer. The subsequent processing mainly involves shaping the organic fertilizer to enhance the appearance of the product.

.jpg)

.jpg)

.jpg)

.jpg)