Generally speaking, to configure a production line for 100 tons of powdered organic fertilizer, the following equipment needs to be considered. Firstly, there is the raw material processing equipment, which includes fermentation turners, organic fertilizer crushers, organic fertilizer mixers, drum screening machines, and packaging machines.

The process flow of the powdered organic fertilizer production line is as follows:

1. Send qualified organic raw materials into the speed regulating silo using a loader;

2. Transported to a vertical crusher for crushing to 10-60 mesh size;

3. Transported to the drum screening machine for sorting raw materials and impurities; Mixing equipment can also be added.

4. Transported to a powder organic fertilizer packaging machine (dedicated) for weighing, packaging, sewing, and storage..jpg)

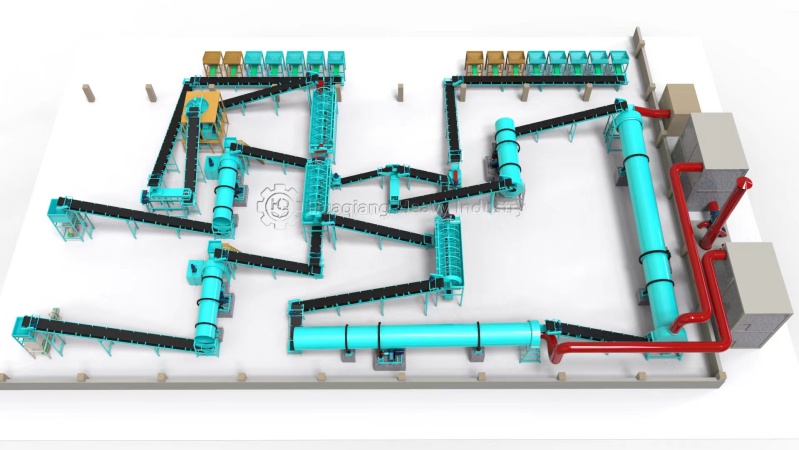

Composition of equipment for organic fertilizer powder production line:

The main equipment of the organic fertilizer powder production line includes six parts: speed regulating feeding bin, feeding belt conveyor, vertical crusher, drum screening machine – quantitative packaging machine, and distribution cabinet;

Suitable for small and medium-sized organic fertilizer production processes with compact layout, scientific and reasonable matching, energy-saving and consumption reduction, no three emissions, automated control, stable operation, reliable operation and convenient maintenance, wide adaptability of raw materials, suitable for various ratios of organic compound fertilizers, bio organic fertilizers, urban sludge, household waste organic fertilizer production, etc. The annual production capacity can be designed according to production needs, ranging from 10000 to 100000 tons.

As for the price of the production line for 100 tons of powdered organic fertilizer per day, the price of different equipment may vary. Based on experience, the equipment budget for the entire 100 ton/day powdered organic fertilizer production line may range from 300000 to 400000 yuan, taking into account factors such as brand, scale, and quality of different equipment.

.jpg)

.jpg)

.jpg)