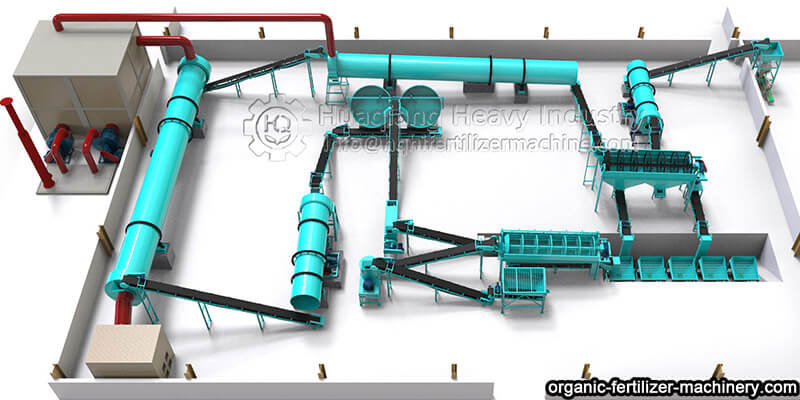

The production of organic fertilizer production lines is a waste utilization and recycling process. The raw materials used in the production and processing of organic fertilizer include feces, crop straw, household waste, sludge left after sewage treatment, etc. These raw materials are considered useless waste to us, and random stacking of these materials can cause certain harm to the environment, But now we can directly use organic fertilizer production lines to process and produce these materials into organic fertilizers that have many advantages for agricultural production, which can truly be regarded as a way to turn waste into treasure. At the same time, the application of organic fertilizer equipment to process and produce the waste left over in various industries has also achieved recycling between different industries..jpg)

The production of powdered organic fertilizers is relatively simple. The production equipment mainly consists of five major components: organic fertilizer stacker, forklift, quantitative feeder, crusher, and screening machine (drum screen or vibrating screen). Before connecting the equipment with the equipment, four sets of belt conveyors need to be used to form a complete production line,

1. There is a belt conveyor above the crusher, which connects the screened large raw materials.

2. A belt above the screening machine is connected to the fermentation material.

3. A belt below the screening machine is connected to the screened finished material, and the finished product is sent to the processing site for weighing and packaging.

4. The warehouse requires a conveyor for loading.

The production line of granular organic fertilizers is relatively complex, mainly using a double roll granulator for granulation. The roller extrusion granulator is a granulation process that utilizes the strong working pressure of machine equipment to polymerize solid materials. This type of granulation feed does not require drying.

The roller extrusion granulator is a widely used granulator in organic fertilizer granulators. The design of the roller extrusion granulator is very reasonable, practical, and low in energy consumption. It can continuously produce one roll forming without the need for drying at room temperature. The ball and socket on the roller skin can be manufactured according to the size and shape of customer needs. Currently, we have produced ball, pillow, semi circular particle, rod, walnut, flat ball, square bar, and so on. New energy-saving products currently used in the compound fertilizer and organic fertilizer industries.

.jpg)