Because of the low utilization rate of chemical fertilizer, people try to make a slow-release and high-utilization fertilizer to meet the demand of nitrogen in different growth stages of crops, reduce the loss of nitrogen leaching and volatilization, reduce the fixation of phosphorus and potassium fertilizers in the soil, so that the fertilizer can supply nutrients according to the requirement of crop fertilizer. The available CaO, MgO, SiO 2 and various trace elements in fertilizers are also good soil amendments. The coated NPK fertilizer manufacturing process can produce suitable fertilizer products.

Slow release coated fertilizer manufacturing process

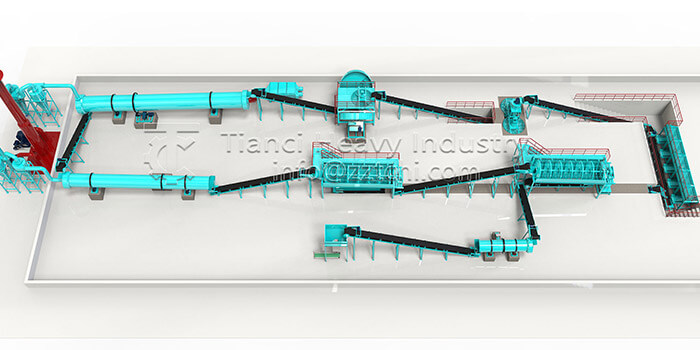

According to the sustainable development of agriculture and the demand of improving fertilizer utilization rate, Zhengzhou Tianci Fertilizer Machine Manufacturer has developed a slow-acting, high-utility coated complex fertilizer manufacturing process. The fertilizer manufacturing process is based on the instant granular fertilizer as the core, one or more slow-release plant nutrients as the coating, inorganic acid complex, slow solvent and other binders to wrap water-soluble fertilizer, forming a complex fertilizer with both quick-acting and slow-acting components. We provide fertilizer manufacturing process including fertilizer granulator machine, pulverizer, rotary dryers, coolers, drum screening machines, coating machines, packing machines and other equipment. The whole set of fertilizer production equipment can complete the processing and coating of the particles of the complex fertilizer, so that the fertilizer has high utilization rate in the soil.

Benefits of NPK Fertilizer Production Process

In the process of fertilizer production, the structure and composition of cladding layer can be adjusted to control the release rate of nutrients so as to reduce leaching loss and improve the utilization rate of fertilizers. This fertilizer product not only has the characteristics of slowly releasing nutrients, but also can meet the needs of nutrients for the whole growth period of crops and the ratio of nutrient utilization rate by one basal application. Conventional quick-acting fertilizer increased by 10-30 percentage points, the utilization rate of nitrogen fertilizer could reach 50%-70%, and the amount of fertilizer used could be reduced by 10%-40%. Due to the remarkable economic and social benefits of slow-acting and high-utilization wrapped complex fertilizer, and in line with the direction of fertilizer development, it is worth vigorously promoting.