Plant burn from organic fertilizer is essentially root damage caused by improper application, not a problem with the organic fertilizer itself. The core of prevention is “controlling composting, controlling dosage, and controlling application method.” Relying on standardized organic fertilizer production equipment for proper pre-treatment and proactive control throughout the entire process can maximize the soil-improving benefits while eliminating the risk of seedling burn.

Strictly control the quality of composting to avoid potential problems at the source. Uncomposted organic fertilizer is the main cause of seedling burn. It needs to be composted using a compost turning machine in the organic fertilizer production line until the material is dark brown, odorless, loose, and easily crushed before application. Avoid directly using fresh livestock manure.

Scientifically control the dosage, adapting to soil and crop. Adjust the dosage according to soil fertility and crop variety. Increase the dosage appropriately for infertile soils and reduce the dosage for fertile soils to avoid excessive organic matter concentration leading to root dehydration. Follow the “small amounts, multiple times” principle, differentiating the dosage for field crops and fruit and vegetable crops.

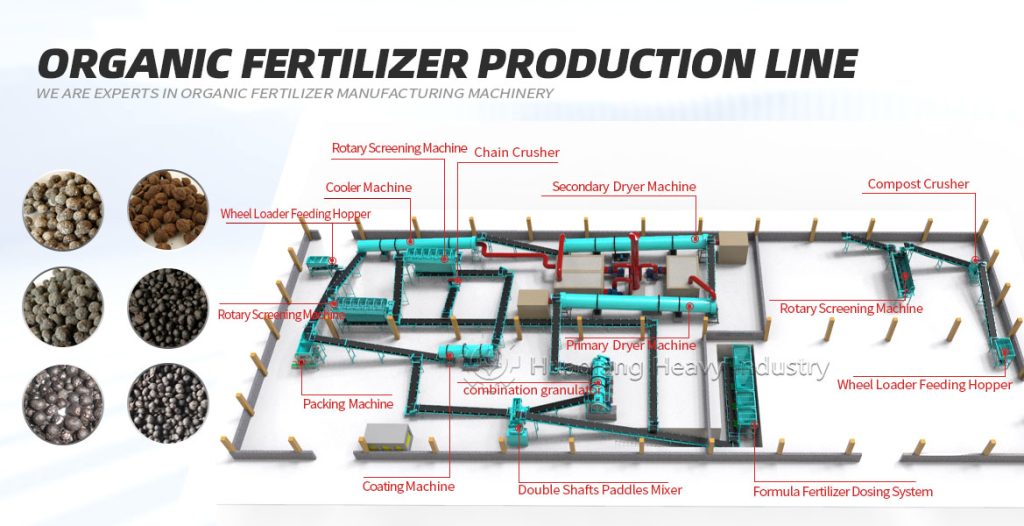

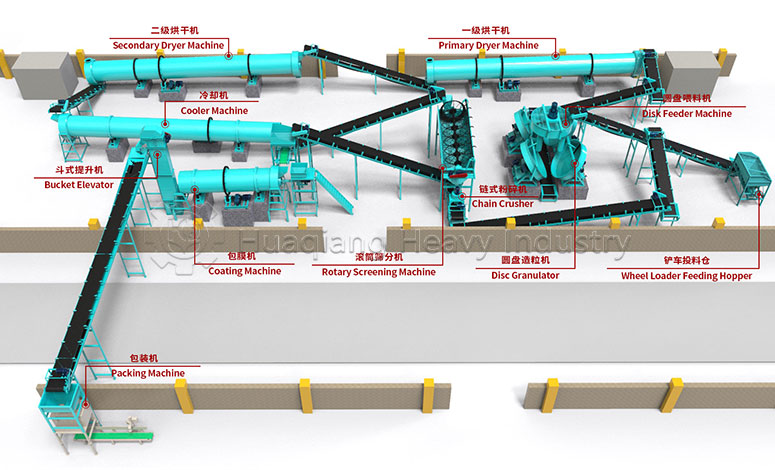

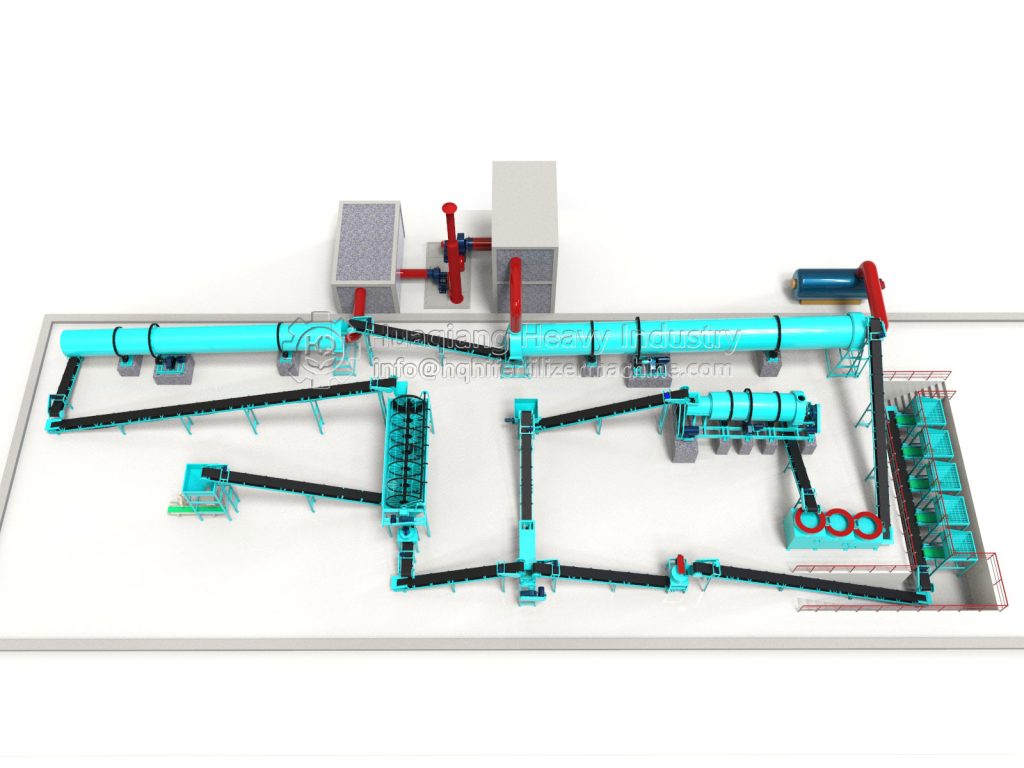

Standardize application methods to avoid excessively high local concentrations. Mix organic fertilizer thoroughly with the soil, keeping it away from crop roots. When applying in furrows or holes, maintain a 10-15 cm distance from the roots and cover with soil. For fertigation, dilute the fertilizer before watering to avoid localized accumulation. Use granular or powdered organic fertilizer processed using appropriate organic fertilizer production equipment.

Proper post-planting care and timely remedial measures are crucial. If crops show yellowing or wilting, immediately water with clean water to dilute the fertilizer concentration, improve ventilation and light penetration to promote root recovery, and minimize the risk of seedling burn.