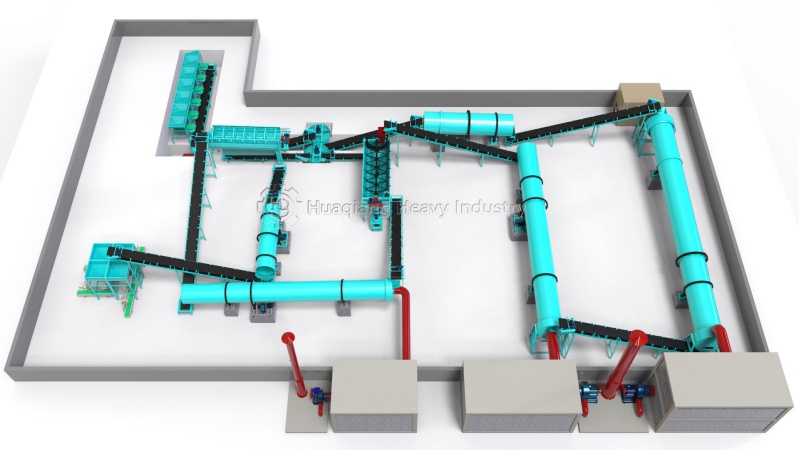

NPK fertilizer manufacturing process of rotary drum granulator

1.In the solid granulation process of rotary drum granulator, urea, ammonium chloride, ammonium sulfate, potassium chloride and other single base fertilizers are used as raw materials and mixed in a certain proportion (mainly determined by the local market demand and soil testing results).

2.Then evenly mix the distributed raw materials with a fertilizer mixer, and crush them to a certain fineness. Next is the main necessary step – granulation, here you need a drum granulator.

3.The material is sent to the drum granulator by belt conveyor, and agglomerates and forms particles through a series of humidification and heating processes.

4.The particles here are only semi-finished products. They need further processing, including drying, screening, cooling and packaging. After all these procedures, high quality compound fertilizer products can be obtained.

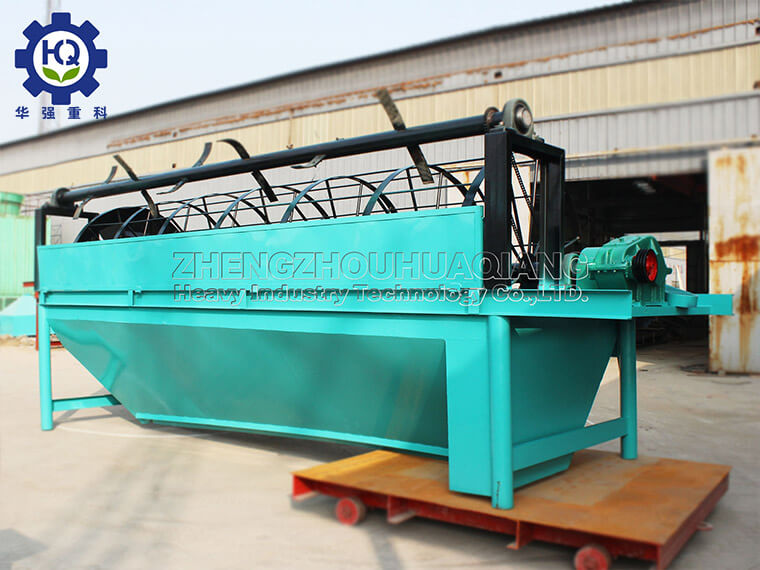

Introduction of rotary granulatorDrum granulator is a key machine in NPK fertilizer production line, which is suitable for cold and hot granulation in large and medium-sized compound fertilizer plants. It and the general fertilizer granulator, are wet granulation, by adding a certain amount of water and steam, the raw materials in the rotary drum in the granulation process will become uniform wet. Then, as the drum rotates, the material will join and roll into particles. The fertilizer particles are spherical, 3-4mm in diameter.

Advantages of rotary drum granulator

1. High granulation rate, drum granulator can adjust speed and control granulation.

2. Using solid granulation method, raw materials are easy to obtain and processing is relatively simple.

3. Liquid and steam injection is easy, and pipes and frames are provided.

4. Low investment, low production cost and high return.

5. The drum granulator uses anti-corrosion rubber engineering plastic as the inner lining to better protect the material from harm to the drum.

6. The produced particles belong to the secondary processing of base fertilizer, so there is almost no environmental pollution problem.

7. High-quality steel and gears, stable work and low noise.

8. Equipped with handrail shovel which helps the roller cleaning.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)