In the organic fertilizer production line, the organic fertilizer crusher is one of the indispensable organic fertilizer equipment. It has the following characteristics and uses, so that it plays an irreplaceable role in the production process.

1, organic fertilizer crusher has high efficiency crushing ability. It can break and crush all kinds of organic waste, so as to facilitate subsequent processing. Compared with other types of grinders, organic fertilizer crushers have higher production capacity and shorter processing time, which can greatly improve production efficiency.

2, organic fertilizer crusher has a wide range of applicability. It is suitable for a variety of different types of organic waste, such as livestock manure, crop straw, municipal waste and so on. By using organic fertilizer shredders, these wastes can be effectively converted into organic fertilizers, thus meeting the needs of agricultural production.

3, organic fertilizer crusher also has environmental protection performance. It can effectively reduce the volume and weight of waste, thereby reducing pollution to the environment. At the same time, it can also effectively remove harmful substances in waste, such as heavy metals, pathogenic microorganisms, etc., so as to ensure the safety of the produced fertilizer.

4, the operation and maintenance of organic fertilizer crusher is simple. It adopts advanced mechanical design, simple structure, convenient operation and easy maintenance. At the same time, it also has high durability and reliability, and can run stably for a long time, thus ensuring the stability and continuity of the production line.

The working principle and application of the roller extrusion granulator for organic fertilizer equipment

The output product of the organic fertilizer equipment’s roller extrusion granulator is cylindrical particles. This machine adopts a new technology of bidirectional spiral counter current collision granulation, which enables organic materials to achieve continuous, high-speed, and reciprocating kneading and shearing in the granulation area, forming a high-pressure mechanical flow state collision flow, rapidly changing the molecular structure and granulation properties of materials, significantly enhancing heat transfer, fluidization, and extrusion processes between materials, significantly improving granulation density and sphericity, and significantly reducing energy consumption and template costs.

The main uses of the organic fertilizer equipment for the roller extrusion granulator are:

The organic fertilizer granulator is widely used for direct granulation production of pure organic, organic-inorganic, and bio organic fertilizers from organic materials such as poultry manure, urban sludge, household waste, sugar factory filter sludge, papermaking sludge, distiller’s grains, soybean residue, straw, and peat.

The working principle of the roller granulator for organic fertilizer equipment:

The organic fertilizer equipment adopts a new technology of bidirectional spiral counter current collision granulation for the roller squeezing granulation model, which allows organic materials to achieve continuous, high-speed, and reciprocating kneading and shearing in the granulation area, forming a high-pressure mechanical flow state collision flow. The material temperature rises to 60 degrees Celsius or above within 20 seconds, rapidly changing the molecular structure and granulation properties of the material, significantly enhancing the heat transfer, fluidization, and extrusion processes between materials, The granulation density and pelletizing rate have significantly increased, while energy consumption and template costs have been significantly reduced. The granulation efficiency is more than 50% higher than that of traditional extrusion pelletizers. The motor power is reduced by 40% compared to traditional extrusion granulators.

Application and precautions of belt conveyor in organic fertilizer production line

Belt conveyor is one of the indispensable key equipment in organic fertilizer production line. It is mainly used to transport raw materials, finished products and other materials from one place to another, with high efficiency, stability, environmental protection and other characteristics. The following will give you a detailed introduction to the belt conveyor operation and precautions.

1. Operation steps

1. Check before starting: ensure that there are no obstacles around the belt conveyor, the power supply is normal, the components are firmly connected, and there is no abnormal wear.

2. Start: start the motor first, then start the conveyor belt, and confirm the normal operation before it can be put into use.

3. Operation: Control the speed of the conveyor belt to ensure uniform conveying of materials. If you need to stop, stop the material supply first, then stop the conveyor belt.

4. Precautions: It is strictly prohibited to overload, and it is strictly prohibited to mix metal and other hard objects in the material, so as not to damage the organic fertilizer equipment..jpg)

Ii. Precautions

1. The operator should be trained and familiar with the operation process and precautions of the organic fertilizer production line.

2. During the operation of the equipment, it is forbidden to touch the moving parts.

3. Check the wear of each component regularly and replace the wearing parts in time.

4. Regularly clean up the accumulation and dust around the belt conveyor to ensure the normal operation of the equipment.

5. If abnormal sounds, sparks and other abnormal phenomena are found, they should be stopped immediately for inspection, and then used after troubleshooting.

6. It is strictly prohibited to disassemble and repair the equipment without permission. If there is a fault, contact professional maintenance personnel in time.

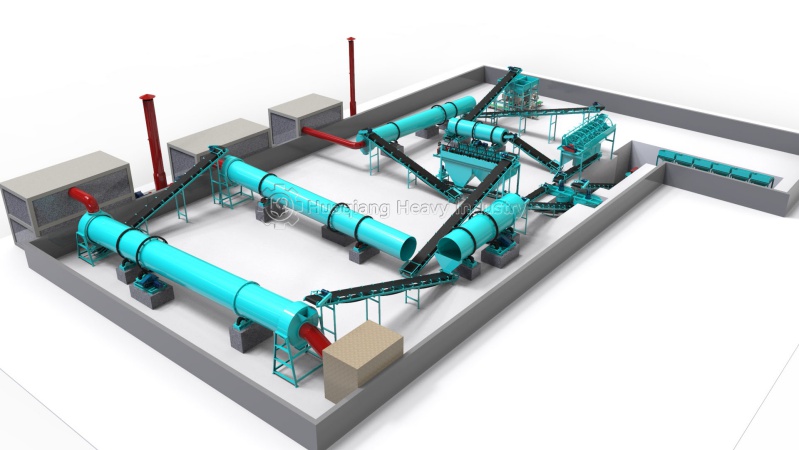

Equipment and revenue of a powdered pig manure organic fertilizer production line

A set of powdered pig manure organic fertilizer production line is relatively simple to make powdered organic fertilizer. A set of powdered pig manure organic fertilizer production line mainly consists of five major components: organic fertilizer tank tipping machine, forklift, quantitative feeder, semi wet material crusher, and screening machine (drum screening machine or vibrating screening machine). Four sets of belt conveyors are needed to connect the equipment to form a complete production line.

A set of powdered pig manure organic fertilizer production line refers to the fertilizer produced by fermenting organic raw materials in a certain proportion without causing particles. There is a certain difference from traditional composting fermentation, with a standard of 40% organic matter, over 5% total nutrients, and 30% moisture. The equipment is also relatively simple, mainly consisting of three stages of fermentation: pre mixing, flipping, refining, and packaging. The main purpose of fermentation is to decompose large molecular materials of organic raw materials into small molecular materials that can be absorbed and utilized by crops through microbial decomposition. The quality of fermentation also affects the quality and effectiveness of organic fertilizers..jpg)

The products produced by the construction of a small-scale pig manure organic fertilizer production line are made from fresh chicken and pig manure as raw materials, without any chemical components. However, pigs and chickens have poor digestion ability and can only consume 25% of the nutrients. The other 75% of the nutrients in the feed are excreted with the manure, resulting in dry products containing nitrogen, phosphorus, potassium, organic matter, amino acids, proteins, and other components. Organic fertilizers have not only created economic benefits for enterprises, but also made significant contributions to human environmental protection projects.

The construction of a small-scale pig manure organic fertilizer production line mainly consists of fermentation and flipping equipment, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation equipment, and finished product packaging system; The fermentation system for harmless treatment of livestock and poultry manure includes: feed conveyor, biological deodorization machine, mixer, flipper, oxygen supply system, and automatic control system.

Reasons for low granulation efficiency of disc granulators in fertilizer production lines

The reasons for the decrease of pelletizing efficiency of organic fertilizer disc granulator are as follows

1. There are three common faults: 1) the surface wear of the disc and barrel increases the inner diameter of the barrel, resulting in the increase of the residual amount of granulation material and the weakening of granulation when the resistance of the head and splitter plate does not change, resulting in the decrease of granulation efficiency. Therefore, the disc and several barrels were repaired. ② The corrosion of the material to the disc and barrel will also accelerate the wear of the disc and barrel. Judge the material properties. ③ Metal materials mixed into the disc and destroyed the disc.

2. The disc of organic fertilizer granulator machine is inclined excessively. Disc organic fertilizer granulator encountered more problems in the use of tilt control and adjustment, in fact, there is no specific parameter for your reference, but, to adapt to the formation of spherical particles as the basis. The adjustment measure is to adjust the bolt at the bottom of the disc to change the position and angle of the reducer to achieve the purpose of normal use.

3. The pelletizing rate of organic fertilizer disc granulator is low. In addition to the subjective factors of raw material composition, the fineness of raw materials, the water content of raw materials, the addition of auxiliary adhesive components, the angle of disc operation and the remonstrance degree of disc operation are also common problems. According to the causes of the above problems, and then make some improvements, we can achieve our expected value.

4. The difference of particle size is big. This problem is a common problem in the single operation of disc organic fertilizer granulator. The treatment of this kind of problem is generally divided into improving the moisture content and controlling the size of molding particles. After drying, the selected particles were screened.

5. The disc granulator runs unevenly. This kind of failure of disc granulator is usually caused by bearing damage, weight loss of disc body and abnormal motor voltage. Timely maintenance can quickly eliminate the operation fault of the disc granulator. The technology of disc organic fertilizer pelletizer is simple, and don’t panic when it breaks down. Generally, we operate and maintain according to regulations to reduce the occurrence of failures, the fertilizer granulator machine price concessions.

Characteristics of Rounding Machine for Organic Fertilizer Production Line Equipment

Ball shaping machine plays an important role in organic fertilizer production line with its unique performance characteristics. This article will introduce the characteristics of the round polishing machine in detail, so that readers can better understand its working principle and advantages.

First of all, the round polishing machine is an efficient granulation equipment, which can quickly make the raw material into round particles. It has high production capacity and precise granulation effect, and is suitable for the treatment of various organic wastes. Organic waste can be quickly converted into organic fertilizer products that are easy to store and transport through the processing of the round polishing machine.

Secondly, the polishing machine has a high degree of automation. It uses an advanced control system to automatically adjust granulation parameters to ensure the stability and continuity of the production process. In addition, the round polishing machine is also equipped with safety protection devices to ensure the safety of the operator.

In addition, the polishing machine has a long service life. It uses high-quality wear-resistant materials and advanced manufacturing processes to withstand the high-intensity granulation process, reducing the wear and maintenance costs of organic fertilizer equipment. At the same time, the maintenance of the polishing machine is simple and convenient, and the operating cost is reduced.

Finally, the polishing machine has environmental protection performance. It can effectively reduce the discharge of waste, improve the utilization rate of resources, and reduce environmental pollution. At the same time, the round polishing machine also has high production efficiency, which can meet the needs of organic fertilizer production.

In summary, the round polishing machine in the organic fertilizer production line equipment has the characteristics of high efficiency, high degree of automation, long service life and good environmental performance. These characteristics make the round polishing machine play an important role in the production of organic fertilizer, and make a positive contribution to the cause of environmental protection.

The granulation process and advantages of organic fertilizer conversion granulator

The organic fertilizer high-speed conversion composite granulator is a molding machine that can manufacture materials into specific shapes. Suitable for large-scale production of cold and hot granulation, as well as high, medium, and low concentration compound fertilizers. The main working method is wet granulation of pellets. By using a certain amount of water or steam, the basic fertilizer is fully chemically reacted in the cylinder after being humidified. Under certain liquid phase conditions, with the help of the rotational motion of the cylinder, the material particles are compressed and agglomerated into balls.

The drum granulator has the characteristics of beautiful appearance, simple operation, low energy consumption, long service life, uniform drying, and convenient maintenance. It is suitable for cold and hot granulation, as well as large-scale production of high, medium, and low concentration compound fertilizers and mixed fertilizers. Heating with steam, increasing material temperature, reducing moisture content after material balling, and improving drying efficiency. The cylinder body is lined with special rubber plates or acid resistant stainless steel plates, which prevent the raw materials from sticking to the cylinder and provide anti-corrosion and insulation effects. It has low power consumption, low maintenance costs, low investment, fast effectiveness, good economic benefits, and reliable performance.

The cylinder of the organic fertilizer high-speed conversion composite granulator adopts a special rubber plate lining or acid resistant stainless steel lining plate, achieving automatic scar removal and tumor removal, and eliminating the traditional scraper device. This machine has the characteristics of high ball forming strength, good appearance quality, corrosion resistance, wear resistance, low energy consumption, long service life, and convenient operation and maintenance.

The working principle of the organic fertilizer high-speed conversion composite granulator is that the material enters the front end of the rotating cylinder through the feeding pipe (the slope of the feeding pipe should be greater than the natural inclination angle of the material). The steam inlet pipe located at the front end of the cylinder sprays a certain pressure of water vapor. Due to the fact that the inlet nozzle is located at the bottom of the material. And steam has a certain pressure. Therefore, the material can obtain some moisture more evenly and form smaller particles.

How to choose a suitable chicken manure granulator to process fertilizer in a chicken farm?

My company produces fertilizer granulation machine has disc granulator, npk fertilizer granulator, double roller granulator, organic fertilizer granulator machine, drum granulator, flat die pelleting machine, and ring die pelleting machine. Fertilizer granulator machine price concessions, stable operation, convenient maintenance, quality assurance, the majority of users like!

For example, the production of granules can choose disc granulator, new organic fertilizer special granulator, drum granulator.

If the production of columnar on the choice of ring die granulator, flat die granulator.

Irregular, flat ball on the choice of double roller extrusion granulator (according to the mold).

All kinds of granulating equipment have advantages and disadvantages. The moisture, temperature, pH value and fineness of materials may affect the selection of fertilizer granulator. According to the raw materials, investment cost, according to the needs of customers, equipment selection is different. The fertilizer granulator machine price varies according to specifications and types.

Zhengzhou Huaqiang Heavy Industry Machinery Ltd adheres to market orientation, innovation and development, quality and survival, and perfect after-sales service to win the trust of customers. We mainly produce organic fertilizer granulator machine, crusher, mixer, conveyor, compost windrow turner, coating machine, packaging machine, dryer, cooler, screening machine, as well as different types of fertilizer production lines, including organic fertilizer production line, bio organic fertilizer production line, NPK fertilizer manufacturing process, BB fertilizer production line. Warmly welcome people from all walks of life to visit the company, mutual benefit, win-win, create a better!

Proper use of sheep manure organic fertilizer production line to extend service life

Proper use of sheep manure organic fertilizer production line to extend service life

1, regular inspection and maintenance

During the operation of the organic fertilizer equipment, the working status of each component should be regularly checked, such as whether the conveyor belt is loose, whether the host bearing is worn. If the problem is found, it should be repaired or replaced in time to avoid greater losses.

2. Keep the equipment clean

Organic fertilizer production line in the process of use, it will inevitably be contaminated with dust, dirt and other impurities. Therefore, the equipment should be cleaned regularly to ensure its internal cleanliness and prevent damage to the equipment.

3, regular lubrication maintenance

Regular lubrication maintenance of the equipment can effectively extend the service life of the equipment. Appropriate lubricants should be selected to regularly lubricate key parts such as the main engine and mixing system to ensure the normal operation of the equipment.

4. Rational use of organic fertilizer equipment

In the process of use, it should be strictly operated in accordance with the operating procedures to avoid overload operation. At the same time, the device should be regularly checked, and any abnormal situation should be adjusted in time to ensure the normal operation of the device.

In summary, the service life of sheep manure organic fertilizer production line can be effectively extended by regular inspection and maintenance, keeping equipment clean, regular lubrication and maintenance, and rational use of equipment. At the same time, we should also strengthen the awareness of equipment maintenance, timely detection and solution of problems, to ensure the normal operation of equipment.

Notes on the granulation process of the roller squeezing granulator

The organic fertilizer granulator, also known as the roller extrusion granulator, produces cylindrical particles as the finished product. This machine adopts a new technology of bidirectional spiral counter current collision granulation, which enables organic materials to achieve continuous, high-speed, and reciprocating kneading and shearing in the granulation area, forming a high-pressure mechanical flow state collision flow, rapidly changing the molecular structure and granulation properties of materials, significantly enhancing heat transfer, fluidization, and extrusion processes between materials, significantly improving granulation density and sphericity, and significantly reducing energy consumption and template costs.

The working principle of the roller squeezing granulator is that the material is squeezed downwards by the grinding wheel, then cut by a scraper, and then enters the secondary combination polishing and rolling to form a ball in one go; The organic fertilizer extrusion granulator has the advantages of high pelletizing rate, no return material, high particle strength, uniform roundness, low pelletizing moisture, and low drying energy consumption.

Precautions for the roller extrusion granulator during granulation:

1. When using, attention should be paid to the absence of hard objects such as stones and iron blocks in the raw materials. After working for more than ten shifts (8 hours per shift), the rollers need to be cracked and removed. High temperature resistant grease should be added to the bearings to improve their working performance and extend their service life;

2. During granulation, it is strictly prohibited for the pressure roller to come into contact with the template and rotate freely;

3. If the particles appear fragmented or not compacted, the formula of the coarse fiber material should be reduced to within 50%;

4. If there is no granulation or discharge during granulation, the membrane plate should be removed, and after opening each hole, some fiber materials should be added appropriately to restart granulation;

5. The tightness of the belt should be checked regularly, and if there is any oil leakage in the gearbox, the oil seal should be replaced in a timely manner;

6. The vulnerable parts in the flat film granulator include rolling bearings, film plates, pressure roller motors, V-belt pressure roller shafts, and crushing blades.