In the 1990s, the Chinese government made plans and action deployments for the comprehensive utilization of crop straw resources. Mainly including the following aspects: 1. As of the end of 2000, the country had invested 367 million yuan in building 13 straw livestock demonstration zones and 380 demonstration counties nationwide, directly promoting the development of herbivorous livestock in China. With the deepening of the government’s understanding of the ban on straw burning, in May 1998, China decided to implement a national demonstration project for straw gasification. The country allocates a portion of funds annually to support the promotion of straw gasification technology in rural areas, solve rural energy consumption problems, and alleviate rural environmental pollution. The technological innovation of straw comprehensive utilization in the 3 straw innovation industries has been listed as one of the focuses of the Ministry of Science and Technology in recent years, including straw fertilizer technology, straw feed technology, straw fuel technology, straw industrial raw material technology, and straw as a substrate for edible fungi technology. Overall, the comprehensive utilization of straw in China started relatively late compared to developed countries abroad, but the results of comprehensive utilization are relatively significant..jpg)

It is not only an energy project, but also conducive to promoting the industrialization of bioenergy. It is also a good agricultural development project. Using straw to produce organic fertilizer can effectively improve the growth environment of crops, increase their yield and agricultural benefits, and is conducive to increasing farmers’ income and efficiency. It is very in line with the needs of China’s comprehensive promotion of new rural construction and has broad application prospects in rural areas.

The straw organic fertilizer production equipment can quickly and harmlessly solve the problem of agricultural waste such as straw, wheat straw, corn straw, and vegetable residues, edible mushroom residues, plant manure, tobacco residues, etc. that are casually discarded in the field and rotting or burning in the open air. It can completely eliminate diseases, pests, and weeds in agricultural waste and quickly convert them into excellent organic fertilizer. The birth of straw organic fertilizer equipment can harmless solve the problem of straw burning. This production equipment has the advantages of low investment, small land occupation, high profits, and good efficiency. The straw organic fertilizer production equipment is used to process and ferment the remaining stem and leaf parts of corn, rice, wheat, and other cereal crops after ripening and threshing. After preliminary fermentation treatment and later deep processing and granulation, qualified commercial organic fertilizers are produced.

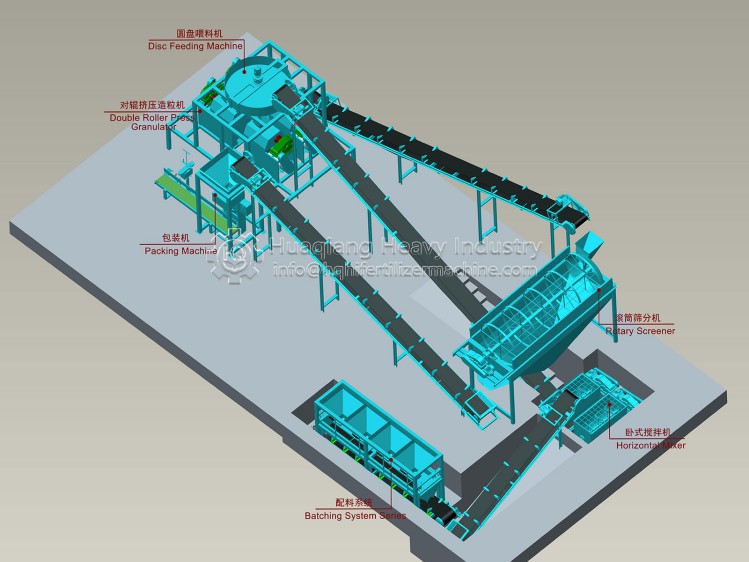

The machinery commonly used in straw organic fertilizer production equipment includes: organic fertilizer stacker, organic fertilizer crusher, organic fertilizer mixer, organic fertilizer granulator, rotary dryer, rotary cooling machine, organic fertilizer screening machine, organic fertilizer coating machine, organic fertilizer packaging equipment, organic fertilizer belt conveyor, etc.

.jpg)

.jpg)

.jpg)