Chicken manure has high nutritional value. It is processed into chicken manure Manure for sale, which is a form of recycling aquaculture emissions. It can promote the improvement of environmental protection problems in the aquaculture industry, and can bring additional economic benefits to the farm.

The fertilizer production line for chicken manure production of Manure includes five links:.jpg)

1. Chicken manure Organic fertilizer fermentation equipment:

The main function of the fermentation part of the Manure production line is to initially reduce the water content in the raw materials of Manure. As we all know, the raw materials of Manure are mainly chicken manure, pig manure, cow manure, sheep manure and other animal manure. Cow manure and sheep manure are OK, and the humidity of chicken manure and pig manure is too high. Especially, the initial humidity of chicken manure is generally above. Such high humidity cannot be directly treated, and must be fermented in a fermentation tank first.

Generally speaking, after about a week of fermentation, the humidity of fresh chicken manure can be reduced to below. Another tip to share is that during the fermentation process of chicken manure, some coarse fiber materials such as bran and wheat bran can be added to reduce the fermentation time and costs.

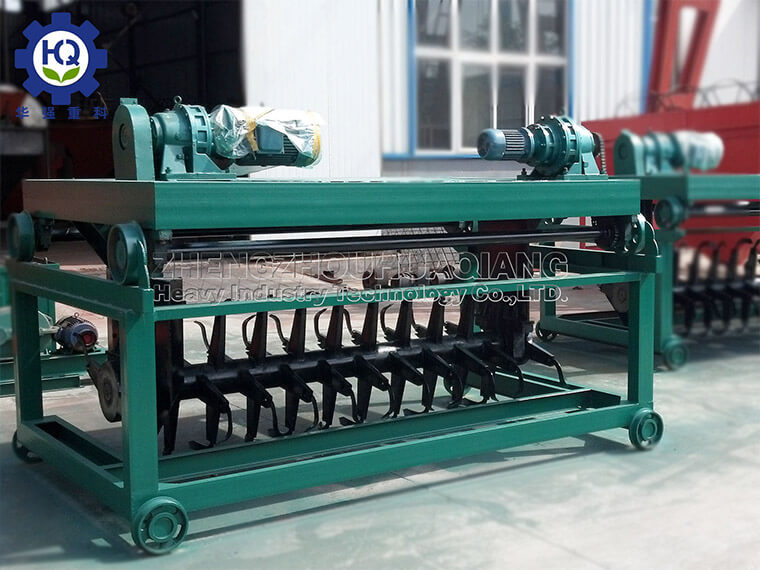

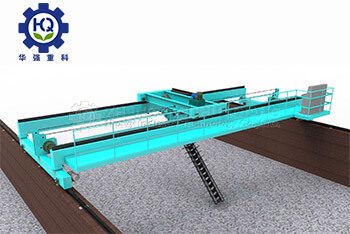

2. Crushing equipment:

Fermented animal excrement will be caked, and block materials are not easy to dry directly. Therefore, it is recommended to use a small grinder to crush them first before moving on to the next step. In Manure equipment, the crushing part is often necessary.

3. Drying equipment:

Seeing this, some friends may want to ask, why do we need to dry it again if there is no fermentation process ahead. In fact, the fermentation can only control the humidity around. To make Manure granules, the moisture must also be controlled. Therefore, the drying process is also essential.

4. Granulation equipment:

Organic fertilizer granulator is the core link of the whole Manure production line. Generally speaking, we recommend using a combination of granulators and ball shaping machines to achieve granulation functions, and do not recommend using traditional disc granulators. The advantage of doing so is that the particle forming rate is high and the compactness is good.

5. Cooling and packaging equipment:

The cooling and packaging processes can be ignored for small volume users. Small production users can directly air dry and manually bag. Only the complete set of Organic fertilizer production lines with large output need automatic packaging machines.

What is explained here is that a complete chicken manure Organic fertilizer production line is generally not composed of a single equipment, but usually consists of two or three equipment combinations, so the price of chicken manure composting equipment is more difficult to determine, usually between 100000 and millions, depending on the actual situation. As long as the equipment is properly matched and the manufacturer is selected correctly, it can ensure that the user’s investment is small and the later profits are higher.

.jpg)

.jpg)

.jpg)

.jpg)