Is there dust pollution in the chicken Organic fertilizer production line? How to solve the problem of dust removal? When Organic fertilizer production line equipment is used to make Organic fertilizer, a small amount of dust will also appear on individual sites, which requires that these dust be removed..jpg)

1. In the whole Organic fertilizer production line, when the materials are dried, a certain amount of fine dust will be produced. We can extract these dust for precipitation and filtration through the cyclone dust collector or water curtain dust collector, which solves the problem of dust. Because of limited funds, friends can build a small dust chamber next to the dryer, and pump the dust into the dust chamber through the fan for static setting.

2. During the construction of Organic fertilizer equipment, most of them use organic wastes and perishable substances. So the storage and unloading of raw materials will generate odor. In addition, the storage sites for raw materials, auxiliary materials and compost, as well as the platform between fermentation facilities accessed by Cart, etc. It can produce dust and unpleasant gases. Although auxiliary materials such as rice husks and sawdust do not produce unpleasant gases, they produce a large amount of dust when unloaded.

3. When the shredder in the Organic fertilizer equipment is used to crush rice husks, dust and water vapor will also be generated when the crushed rice husks are transported. When crushing and pruning, if a shear crusher is used, there is basically no dust generated. However, if high-speed rotary crushing and air conveying are used to crush and prune, a considerable amount of dust and noise will be generated.

4. In the mixing equipment, various raw materials are fed into the mixer, especially during the discharge of low moisture content compost returns and mixed raw materials, which can also generate odor and dust.

5. In the fermentation process, the decomposition of organic matter produces ammonia gas. Through the input of raw materials into the fermentation facility and the discharge of compost through the fermentation facility, odor and dust are generated during repeated operations in the secondary fermentation tank. The decomposition of organic matter will cause the temperature of raw materials to rise and generate a large amount of water. In the process of repeated operation, water vapor, dust and gas will be mixed together, resulting in white fog in the fermentation room of Organic fertilizer equipment. The odor and water vapor generated during the fermentation process will significantly decrease with the end of the first fermentation, and will basically disappear upon the completion of the second fermentation. The decrease in moisture in compost is accompanied by a decrease in moisture, which in turn generates dust. During the repeated use of secondary fermentation facilities, water vapor and dust will be generated simultaneously.

6. After the chicken organic fertilizer Organic fertilizer production line is used for a long time, some dust will accumulate. If the dust is not cleaned in time, the use effect of the equipment will be affected. The dust pollution on the chicken organic fertilizer Organic fertilizer production line may be caused by high potential energy difference.

Utilize transportation equipment with good sealing performance to reduce the height difference and inclination of the unloading logistics, and set up flow separation facilities as much as possible. Not only can it enhance the flexibility and efficiency of the configuration between various operations, but it can also reduce scattering and dust. Utilize exhaust systems. In order to prevent dust from causing more pollution, indoor dust can also be removed through the exhaust system, which means removing indoor exhaust gas.

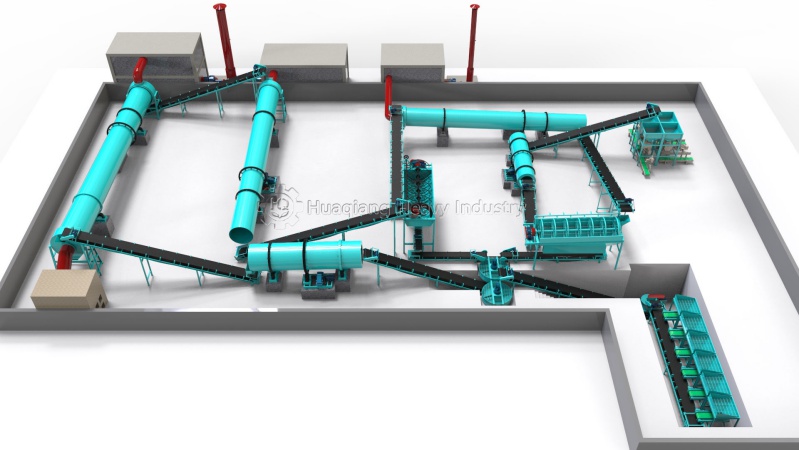

The chicken organic fertilizer Organic fertilizer production line will send all kinds of high humidity and high viscosity organic wastes (such as livestock organic fertilizer, chemical, paper making, brewing, food organic waste residue) that need to be dried into the high humidity material dryer through the conveying system, which will be lifted by the special board on the inner wall of the cylinder. The rapidly rotating mixing wing in the middle of the cylinder repeatedly crushes the wet material, allowing for sufficient heat exchange between the material and the high-temperature hot air with slight negative pressure. Due to the combined effect of the cylinder inclination angle and introduction, the material slowly moves forward and flows out from the tail; The exhaust gas is discharged up to standard through cyclone dust removal and water bath dust removal.

.jpg)

.jpg)

.jpg)

.jpg)