The fertilizer granulator machine of organic fertilizer is the key equipment for the production of organic fertilizer in the production line of organic fertilizer.It makes the raw material of organic fertilizer into particles,makes the shape of organic fertilizer good,and improves the utilization rate of fertilizer.Apart from organic fertilizer granulator,there are many other types of fertilizer granulator,such as disc granulator,flat die granulator,and rotary drum granulator and so on.

Because of its unique structure and pelletizing technology,organic fertilizer granulator plays an important role in organic fertilizer production line.

The disk granulator of organic fertilizer has made great contribution to the realization of agricultural pollution-free.In addition to the normal growth of crops,most of the chemical fertilizers are washed away by rainwater,wich will also lead to metal pollution of soil and agricultural products,water eutrophication,water,soil and environmental pollution,and avoid adverse factors.Chemical fertilizer can reduce the pollution of water,soil and environment,and reduce the threat to human and animal survival.It is benefical to the ecological environment.The granulator of organic fertilizer is conducive to the mass production of organic fertilizer,and the use of organic fertilizer in agriulture is helpful to improve the environment.

Besides the disk granulator which it is to be equipped in organic fertilizer production line,it is also to be equipped in npk fertilizer production line to make compound fertilizer granulator.More other series fertilizer machine is also necessary.In a complete fertilizer production line,it also needs to use the fertilizer crusher machine,fertilizer mxier machine and so on.

The fertilizer machine manufacturers designed all types of fertilizer machines and fertilizer production line to make the fertilizer granulator or fertilizer powder.In the fertilizer production line,using the automatic or semi-automatic fertilizer machine to finish the production process not only improve the working efficient,it also saves more labor cost.At the same time,it also simpllifies the organic fertilizer production process.

Organic fertilizer composting machine ferments manure to reduce urban pollution in aquaculture plants

To solve urban environmental problems well, the most important thing is to solve the pollution caused by the aquaculture industry, which is also faced by most cities and difficult to solve. To completely solve such problems, it is absolutely necessary to have an organic fertilizer production line. There are farmers of all sizes in every city, and excessive accumulation of livestock manure has occurred in every city. How to centralize their utilization is the top priority in solving urban environmental problems. If we can vigorously promote the use of organic fertilizer production line equipment, we can effectively solve the problem of environmental pollution, while promoting the process of utilizing manure resources.

The tank type tipping machine is suitable for the fermentation and tipping of organic wastes such as livestock and poultry manure, sludge waste, filter sludge from sugar factories, tank residue cake, straw sawdust, etc., and is used for the fermentation, ripening, and moisture removal operations in organic fertilizer plants, compound fertilizer plants, sludge waste plants, horticultural farms, and bisporus cultivation plants.

The main features of the tank type composter are as follows:

1. Suitable for aerobic fermentation, it can be used together with solar fermentation chambers, fermentation tanks, and transfer machines. It can be used together with a moving machine to achieve the function of multiple slots for one machine.

The fermentation tank equipped with it can discharge both continuously and in batches. High efficiency, stable operation, durability, and even turnover.

Centralized control of the control cabinet can achieve manual or automatic control functions.

4. Equipped with a soft starter, the impact load is low during startup.

5. Equipped with a gear extraction and pressure lifting system.

6. The tooth extraction is sturdy and durable, and has the ability to break and mix materials

How to design a complete set of chicken manure organic fertilizer production line

The biofertilizer project has short construction period,high return on investment,small risk and short payback period.Generally,the investment is recovered in one year and the profit is generated in that year.How to design the biofertilizer project?

Generally,production process design includes :

1.High efficient compound bacteria and its propargation technology;

2.Advanced raw material blending technology and biological fermentation;

3.The best special fertilizer formula technology(which can design the best combination product formula flexibly according to the local soil and crop characteristics);

4.Reasonable secondary pollution(waste gas and worry gas)control technology;

5.Complete process equipment design for fertilizer production manufacturing technology.

The process flow:raw material selection(animal manure,etc)drying and sterilization-ingredient mixing -granulation which in this part it is to be equipped with the fertilizer granulator machine to finish,cooling and screening -metering and sealing,- warehousing of finished products.

The complete set of equipment is mainly composed of fermentation system,drying system,deodorization and dust removal system,crushing system,batching system,mixing system,granulation system and finished product packaging system, (harmless treatment of livestock and poultry manure, etc.) the fermentation system includes: feed conveyor, biological deodorizer, mixer, exclusive dumper, oxygen supply system and automatic control system, etc.

These fertilizer equipment is to be designed for different type and series for producing all types of fertilizer,which it is to be equipped in different type and series fertilizer production line,like the organic fertilizer production line.More other type fertilizer equipment to be equipped in the fertilizer production line to make fertilizer is higher efficient and simplify the fertilizer manufacturing process.

Zhengzhou Huaqiang Heavy Industry Machinery Industry CO,LTD is a professional fertilizer machine manufacturing company,we are the professional fertilizer machine manufacturer for producing the organic fertilizer machine and fertilizer production line.We have our own professional fertilizer machine designing team and professional producing team to finish the fertilizer equipment producing.

Npk fertilizer production lines are often equipped with double roller granulator

When making the fertilizer granulator in npk fertilizer production line,the roller press granulator machine to be equipped in the npk fertilizer production line.How to make the npk,compound fertilizer granulator?

In the fertilizer production line,it is to be equipped with different type and series fertilizer machine to finish the production process.In npk fertilizer production line,it is to be equipped with the fertilizer mixer machine series,fertilizer crusher machine series,and fertilizer granulator machine series and so on.Sometimes,these machine also to be used in organic fertiliizer production line.

When using the fertilizer granulator machine to make npk,compound fertilizer granulator,we are first to choose the suitable fertilizer granulator machine.In the npk fertilizer manufacturing process,usually,it is to be equipped with the roller press granulator machine to make the compound fertilizer granulator.The roller press granulator machine to be used in the npk fertilizer production line that it is to be worked with the extrusion method to make granulator.Making the compound fertilizer granulator is not only need to use the roller press granulator machine to finish the granulating process,the rotary drum granulator also can be used to make npk,compound fertilizer granulator.

As the professional fertilizer machine manufacturers,we are not only design the npk fertilizer production line with the roller press granulator machine to mkae the compound fertilizer granulator,we are also designed the biofertilizer project to make bioorganic fertilizer granulator.Because sometime,the raw materials of producing the fertilizer are different,we can be according to the different raw materials and different type fertilizer producing method to make the fertilizer granulator.

Using small organic fertilizer equipment to make manure into organic fertilizer

With the popularization of organic fertilizer equipment, there is an optimal treatment method for manure produced in the aquaculture industry. We can process it into organic fertilizer through organic fertilizer equipment, thereby promoting the development of our agriculture. Generally, due to the funding chain, many friends in the aquaculture industry can choose small organic fertilizer equipment, and small organic fertilizer production lines can still effectively carry out pollution-free treatment of livestock and poultry manure. In fact, organic fertilizer equipment with an annual output of less than 20000 tons belongs to small-scale organic fertilizer production lines.

1. Stack manure and other materials, household garbage, sludge, and other fertilizer making base materials in strips on a flat ground (trough type dumper directly puts the materials into the trough). The stacking width is equal to the stacking width of the equipment, the height should be as high as possible, and the length should be as long as possible, such as 50 meters, 100 meters, etc. The ground should be flat, and both cement and land can be used (as long as they are flat and have a certain hardness). Each 10000 tons of production requires 5 to 6 acres of land, and the floor area of the slot type tipping machine will be relatively small.

2. Sprinkle composting base materials such as piled livestock and poultry manure and other materials, household garbage, sludge, etc. with biological fermentation bacteria (our unit provides technology and fermentation bacteria).

3. Use a tilter or trough type tilter to evenly mix straw, livestock and poultry manure, other materials, household garbage, sludge, (water content should be between 50% and 70%), fermentation bacteria, and other materials. After 3 to 5 hours, deodorization can be achieved. After 16 hours, the temperature rises to 50 degrees Celsius, and when the temperature reaches 55 degrees Celsius, the tilter again increases oxygen. In the future, when the temperature of the material reaches 55 degrees Celsius, the tilter begins to stir, playing the role of uniform fermentation, oxygen enrichment, and temperature reduction, Repeat the next process until thoroughly decomposed.

4. If the water content of livestock and poultry manure and other materials, household garbage, sludge, etc. is too high, it is possible to add auxiliary materials that contain organic matter and are relatively dry and can absorb water, or use the method of reflux to place the last dried fertilizer below to form a choppy shape. Place the livestock and poultry manure and other materials, household garbage, sludge, etc. with a high water content in the middle, allowing the water above to seep into the bottom before dumping.

5. The general composting process takes 7-10 days, but due to different climates in different regions, it may take 10-15 days for the material to fully mature, realizing the characteristics of no odor, no bacteria, insect eggs, weed seeds, high humus content, and high potassium content.

6. Then, equipment such as pulverizers, grading screens, and automatic packaging machines can be used to pack powdered organic fertilizers for warehousing and sales. If it is to produce powdery organic fertilizer, it can be sold on the market after the completion of the above advanced process. However, considering inventory time, fertilizer efficiency maintenance, etc. as a commodity sale, it is necessary to further process the above process into granular organic fertilizer. It is necessary to further process the above process into granular organic fertilizer.

Environmentally friendly small organic fertilizer equipment is supported by the state and enjoys financial subsidies. It has the characteristics of convenient material collection, low cost, fast recovery cost, low energy consumption, good income generation efficiency, no pollution, and high organic content, and can effectively create conditions for improving the soil environment, improving the living environment of farmers, and soil water pollution.

Equipment composition of a 30000t/a cow manure organic fertilizer production line

Organic fertilizer production line to be designed for producing the organic fertilizer.Organic fertilizer production line can be designed for different yield according to different producing requirement.

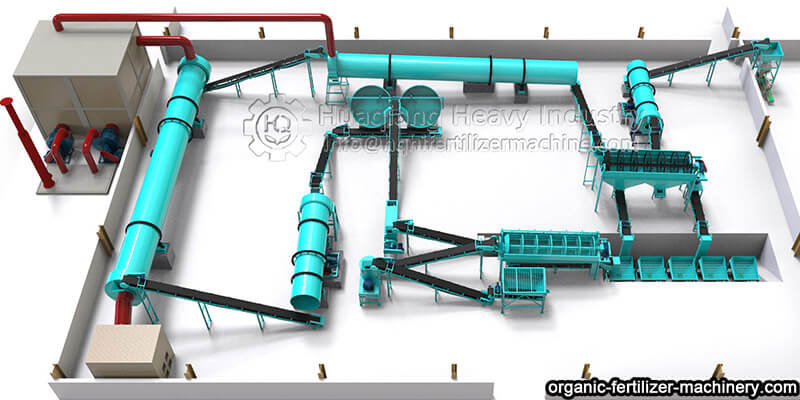

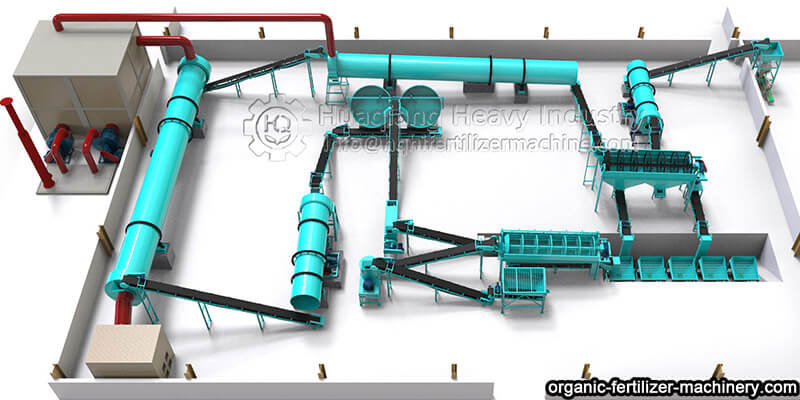

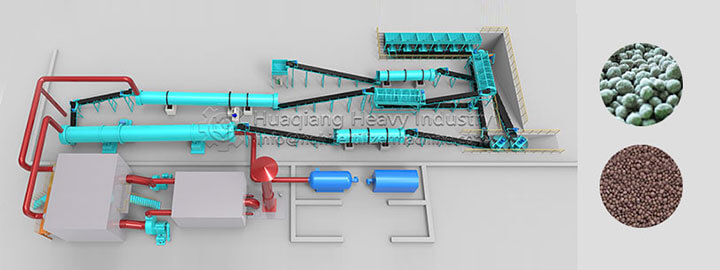

In the fertilizer manufacturing process,the designing of the organic fertilizer production line generally included these fertilizer equipment :It is mainly included the fertilizer mixer machine system with horizontal mixer machine,the fertilizer crusher machine system with half wet material crusher machine and fertilizer granulator machine with we can use the rotary drum granulator machine and so on.dryer machine,cooler machine,screening machine and coating machiine,packaging machine and other series fertilizer equipment.

Zhengzhou Huaqiang Heavy Industry Machinery Equipment Co.Ltd. which we are as the professional fertilizer machine manufacturer,can design 10000-50000 tons of organic fertilizer production line and workshop plant design,organic and inorganic fertilizer equipment,high and low tower fertilizer equipment,drum steam according to the requirements of customers compound fertilizer equipment,urea formaldehyde fertilizer equipment,ammonia fertilizer equipment,ammonia fertilizer equipment,full melt and spray fertilizer equipment,urea based spray fertilizer equipment,extrusion fertilizer equipment,chicken manure and other high humidity materials drying fermentation equipment.

Besides the organic fertilizer production line to be designed and used the fertilizer equipment to make organic fertilizer,there is also designed for the npk fertilizer production line to make npk,compound fertilizer granulator and so on.

Equipment composition of a 30000t/a cow manure organic fertilizer production line

Organic fertilizer production line to be designed for producing the organic fertilizer.Organic fertilizer production line can be designed for different yield according to different producing requirement.

In the fertilizer manufacturing process,the designing of the organic fertilizer production line generally included these fertilizer equipment :It is mainly included the fertilizer mixer machine system with horizontal mixer machine,the fertilizer crusher machine system with half wet material crusher machine and fertilizer granulator machine with we can use the rotary drum granulator machine and so on.dryer machine,cooler machine,screening machine and coating machiine,packaging machine and other series fertilizer equipment.

Zhengzhou Huaqiang Heavy Industry Machinery Equipment Co.Ltd. which we are as the professional fertilizer machine manufacturer,can design 10000-50000 tons of organic fertilizer production line and workshop plant design,organic and inorganic fertilizer equipment,high and low tower fertilizer equipment,drum steam according to the requirements of customers compound fertilizer equipment,urea formaldehyde fertilizer equipment,ammonia fertilizer equipment,ammonia fertilizer equipment,full melt and spray fertilizer equipment,urea based spray fertilizer equipment,extrusion fertilizer equipment,chicken manure and other high humidity materials drying fermentation equipment.

Besides the organic fertilizer production line to be designed and used the fertilizer equipment to make organic fertilizer,there is also designed for the npk fertilizer production line to make npk,compound fertilizer granulator and so on.

the processing technology of cattle manure organic fertilizer production line

The cow manure after composting has realized harmless and stable treatment,which has reached the basic conditions for the utilization of organic manure as a resource,but it has not yet reached the degree of commericialization and sales in the market,and its application effect and scope of use are still limited.Therefore,it is necessary to further proces the compost materials into powdery or granular organic manure with commerical properties through the sunsequent composting process fertilizer,organic-inorganic compound fertilizer and other products.Organic fertilizer production line to be designed for producing the organic fertilizer using the cattle manure.

The organic-inorganic compound fertilizser has dual characteristics,which is,it has the characteristics of long-term effect of organic fertilizer,improving soil and acticvating organic nutrients in soil,and it has the characteristics of high nutrient and quick effect of inorganic fertilizer.It complements each other’s advantages and makes up for each defect,so as to achieve the integration of quick and long-term effect of fertilizer.Organic fertilizer products can support granular or be made to process organic fertilizer into granular products,with cylindrical and spherical particle shape.When making the organic fertilizer granulator,the fertilizer granulator machine is necessary fertilizer machine to finish the granulating process.In organic fertilizer production line we can use the disc granulator machine or the flat die granulator machine to make the organic fertilizer granulator.

Organic fertilizer products can support granular or be made into powder,which depends on market demand.In order to balance nutrients and bu suitable for transportation and storage,it is recommended to process organic fertilizer into granular products,with cylindrical and spherical particle shape.The moisture content of finished product particles shall be:organic fertilizer ≤ 20%; organic-inorganic compound fertilizer ≤ 10%. The processing technology of organic fertilizer mainly includes crushing, batching, mixing, granulating, drying, cooling, screening and packaging. The production capacity of single production line equipment is suitable for 1-10T / h. if it is too small, it will not reach the economic scale. If it is too large, it will increase the difficulty of transportation and storage of raw materials and finished products.

As the professional fertilizer machine manufacturers,we also designed other fertilizer production project to make fertilizer.For example,the biofertilizer project to be designed for producing the bio organic fertilizer.In the fertilizer manufacturing process,it is to be equipped with different type and series fertilizer equipment to finish the production process.

How to Use Organic Fertilizer Equipment to Treat Biogas Residue to Produce Organic Fertilizer

Biogas is a clean energy produced by fermentation of feces, which can be used to replace fuels such as coal for cooking or generating electricity. Manure is left behind after biogas generation. Manure can be fermented to produce organic fertilizer. It is also quite convenient for organic fertilizer equipment to use biogas to produce organic fertilizer. how to use biogas residue to produce organic fertilizer in organic fertilizer equipment:

1. What are the components of dry biogas residue

Biogas residue is a solid substance left behind after the anaerobic fermentation of livestock and poultry manure to produce biogas. Due to long-term immersion in the biogas digester, the moisture content of the biogas residue can be very high. To produce organic fertilizer, it is necessary to separate the dry biogas residue material through a solid-liquid separator, which contains rich organic matter, humic acid, amino acid, nitrogen, phosphorus, potassium, and trace elements. The organic matter calculated by dry matter is generally above 95%, and other components vary depending on their fermentation materials.

2. What is the role of biogas residue

Biogas residue is mainly used to produce organic fertilizer, and organic fertilizer equipment is used as crop base fertilizer and topdressing. Through the application of organic fertilizer, not only the goal of reducing the amount of chemical fertilizer has been achieved, but also the soil has been improved. Biogas residue can also be used as a nutrient soil for preparing flowers, seedlings, traditional Chinese medicinal materials, and vegetable seedlings.

3. Equipment for producing organic fertilizer from biogas residue

Organic fertilizer equipment The production equipment required for producing organic fertilizer from biogas residue from beginning to end include a solid liquid separator, a dryer, a stacker, a belt conveyor, a mixer, an organic fertilizer granulator, an automatic packaging machine, a biogas slurry delivery pump, a liquid fertilizer storage tank, laboratory equipment, and related ancillary facilities.

4. Production process of biogas residue organic fertilizer

The process of producing organic fertilizer by fermentation with biogas residue organic fertilizer equipment is relatively simple. For example, ordinary organic fertilizer equipment only needs to ferment, crush, and screen the biogas residue separated from the solid and liquid, and then bag it. If biogas residue biological organic fertilizer is to be produced, it is necessary to add microbial strains to increase the efficiency of the fertilizer material. If organic fertilizer is made in granules, it requires more equipment and more processing steps. Of course, the fertilizer produced is also very popular in the market.

Design process and granulation advantages of npk fertilizer production line

NPK fertilizer production line to be designed for producing the npk,compound fertilizer.In the npk fertilizer production line,it is to be equipped with different type and series fertilizer machine to finish the production process.How to design the npk fertilizer manufacturing process?There,we are as the professional fertilizer machine manufacturers share some information of the npk fertilizer production line with you.

NPK fertilizer production line to be designed for producing the npk fertilizer powder and npk,compound fertilizer granulator.In the npk fertilizer manufacturing process,it is to be equipped with different type fertilizer machine to finish the prouction process.In npk fertilizer production line,it is to be equipped with the fertilizer mixer machine to mix the raw materials,and it is to be equipped with the fertilizer crusher machine to grind the big and hard raw materials to the powder.And it is also to be equipped with the fertilizer granulator machine to make npk,compound fertilizer granulator,which the fertilizer granulator machine series to be designed for different type and series,we can accordeing to our raw materials and the granulator requirement to choose the suitable fertilizer granulator machine.

The fertilizer manufacturing process flowing:

1)Using the batching system to make the raw materials be ready according to a certain ratio

2)Using the fertilizer crusher machine to grind the big and hard raw materials into the powder

3)Put them into the fertilizer mixer machine to be mixed

4)If we make fertilizer into granulator,using the fertilizer granulator machine to make npk,compound fertilizer granulator.We can choose the roller press granulator machine to make npk,compound fertilizer granulator,which sometimes this type fertilizer granulator machine also can be used in organic fertilizer production line to make organic fertilizer granulator.

5)After graulating,using the fertilizer screener machine to separate the quality fertilizer granulator from the inquality fertilizer granulator.

6)Finally using the fertilizer coating machine to make the fertilizer to be coatied and then put them into the fertilizer packing machine to be packed.