Recently, Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. completed the full-process commissioning of an angle-belt conveyor extrusion granulation production line tailored for a Malaysian client, officially entering the stage of large-scale production. This production line innovatively adopts a Type 7 large-angle bending belt conveyor as the core transfer equipment, integrating the entire chain of processes including raw material storage, precise mixing, efficient granulation, grading and screening, and finished product storage. With its compact layout design, stable material handling capacity, and high-efficiency granulation performance, it has become a benchmark project for fertilizer production equipment in Southeast Asia, providing local enterprises with a highly adaptable and cost-effective mass production solution.

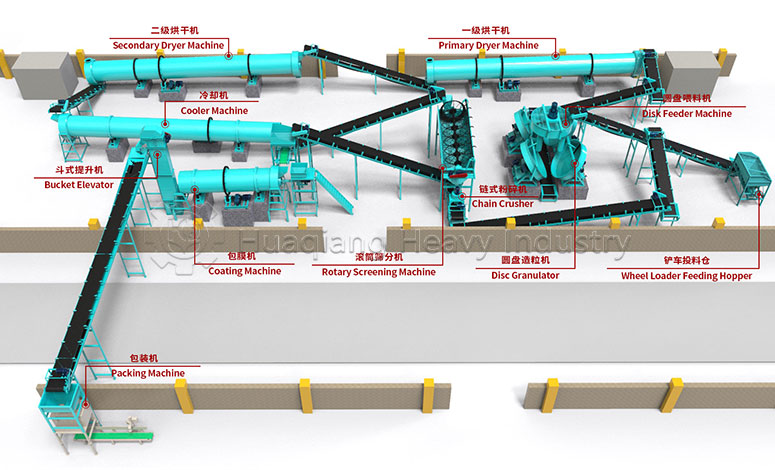

Production Line Full-Process Configuration and Core Equipment Analysis

The entire production line is built around a closed-loop logic of “precise raw material supply – efficient mixing – batch granulation – graded output.” The core highlight is the in-depth application of the Type 7 large-angle bending belt conveyor. The coordinated operation of each unit ensures production efficiency while maximizing the use of factory space, fully meeting the large-scale production needs of the Malaysian client.

Raw Material Storage and Transfer Unit: Large-Angle Belt Conveyor Solves Space Challenges

Raw Material Storage and Discharge: The production line starts with a spiral discharge raw material silo. The silo features a sealed design to effectively prevent moisture absorption, clumping, and dust contamination. A spiral discharge device at the bottom, combined with variable frequency speed control technology, allows for precise control of the raw material discharge rate, adapting to subsequent production rhythms. The total storage capacity of the raw material silo meets the needs of continuous 10 hours of full-load production, supporting the classified storage of main raw materials such as nitrogen, phosphorus, and potassium, as well as various additives, ensuring formula purity.

Large-Angle Bending Belt Conveyor Transfer: Raw materials are transferred over long distances and at large angles via a Type 7 large-angle bending belt conveyor (total length 115 meters, composed of multiple 2-meter, 8-meter, and 15-meter sections). This belt conveyor is a core piece of equipment specifically developed for space-constrained scenarios, with a maximum bending angle of 45°, a 30% increase in transfer angle compared to conventional belt conveyors. It enables efficient vertical and horizontal material transport within limited factory space, significantly saving floor space. The belt conveyor uses a wear-resistant and anti-slip conveyor belt with anti-slip textured surface, coupled with anti-spillage side baffles, effectively preventing materials from sliding and spilling during steep-angle transport. Material transport efficiency reaches 8 tons/hour, with a transport loss rate controlled below 0.5%. The equipment drive system uses an energy-saving motor with operating noise as low as 70dB, and is equipped with an automatic deviation correction device to ensure long-term stable operation.

Raw Material Mixing and Feeding Unit: Laying a Solid Foundation for Uniform Granulation

Dual-Machine Parallel Mixing: After transport, the raw materials are evenly distributed to two horizontal mixers via a three-way distributor. This equipment adopts a dual-shaft counter-rotating design, with impellers made of high-strength alloy material and treated with a wear-resistant coating. During the mixing process, the materials form strong convection and shear forces, ensuring thorough mixing of multi-component raw materials, with a mixing uniformity error ≤2%. The mixer is equipped with an automatic material level monitoring function. When the material in the drum reaches the set capacity, the raw material transfer system is automatically triggered to stop feeding, preventing material overflow or insufficient mixing. After mixing, the material is discharged through the bottom quick discharge port, reducing the discharge time to 2.5 minutes per batch, significantly improving production continuity.

Precise feeding control: The mixed raw materials are uniformly conveyed to the granulator via a spiral feeding hopper. The feeding hopper has a built-in spiral conveyor and material level sensor, which can adjust the feeding speed in real time to ensure uniform feeding of the four extrusion granulators, avoiding granulation quality fluctuations or equipment overload caused by uneven feeding. The feeding hopper adopts a sealed structure, effectively reducing dust emissions during material transfer and improving the production environment.

Core Granulation Unit: Four Machines in Parallel Operation Enables Mass Production Capacity

The core equipment of the production line consists of four extrusion granulators. This model is a mature product developed by Huaqiang Heavy Industry for medium to large-scale production capacity needs. It adopts a high-strength roller extrusion design, with roller skins made of high-chromium alloy. After quenching treatment, the hardness reaches HRC62 or higher, exhibiting extremely high wear resistance and extending its service life to over 10,000 hours. The granulators precisely control the extrusion pressure (6-18MPa) through a hydraulic pressurization system, adapting to the granulation needs of organic fertilizer and compound fertilizer raw materials with different moisture content (25%-32%) and different compositions. The granulation rate is consistently maintained above 93%, with particle size uniformly controlled at 3-5mm and a compressive strength of 2.6MPa, making them less prone to pulverization and fully meeting the needs of local agricultural fertilization and long-distance transportation.

Four granulators operate in parallel, each with an hourly output of 2.2 tons. Combined operation achieves a total capacity of 8.8 tons/hour and a daily capacity of 211.2 tons, significantly improving the customer’s market supply capabilities. The granulators are equipped with an automatic roller cleaning device that removes material adhering to the roller surface in real time, preventing die blockage and ensuring continuous operating efficiency.

Grading and Finished Product Storage Unit: Strict Quality Control and Efficient Delivery

Precise Grading and Screening: Granulated particles are transferred to a linear vibrating screen via a 5-meter belt conveyor. This equipment uses a double-layer screen design; the upper screen separates large, unqualified particles, while the lower screen screens qualified finished products. The screening efficiency reaches 10 tons/hour, with a qualified particle pass rate of 98%. Unqualified particles are returned to the raw material mixing front end via a 7-meter return conveyor and re-enter the granulation process, achieving a material utilization rate of 99% and effectively reducing production costs. The linear vibrating screen is equipped with a vibrating motor and shock absorption device, ensuring stable operation and low noise. The screen mesh can be quickly disassembled and replaced to accommodate different particle size requirements.

Finished Product Storage and Transfer: Qualified granules are diverted to two finished product silos via a three-way distributor. These silos feature a sealed design and are equipped with a dehumidification and ventilation system to effectively prevent fertilizer from absorbing moisture and clumping, ensuring product storage stability. Material level sensors are installed inside the silos to provide real-time inventory feedback, facilitating customers’ efficient shipment planning. Finished products are then transferred to the packaging area via a 3-meter belt conveyor, which can be flexibly integrated with subsequent equipment such as automatic packaging scales, achieving fully automated operation from raw material processing to finished product delivery.

Core Advantages and Regional Adaptability of the Production Line: Ultimate Space Utilization Efficiency: The application of a Type 7 large-angle bending belt conveyor reduces the production line’s footprint by 30% compared to traditional layouts, perfectly adapting to the limited space available in Malaysian factories. The multi-segment splicing design facilitates installation and subsequent maintenance, and the belt length and bending angle can be flexibly adjusted according to the factory layout.

High Efficiency in Both Transfer and Granulation: The large-angle belt conveyor enables stable long-distance, large-angle transfer with low material loss and high efficiency; four granulators operate in parallel to meet the needs of large-scale production capacity, increasing overall production efficiency by 15% compared to conventional production lines of the same scale.

Stable, Reliable, and Highly Adaptable: The core equipment uses high-temperature resistant and corrosion-resistant materials, adapting to the hot and humid climate conditions of Malaysia; the extrusion granulator can flexibly adapt to various materials such as organic fertilizer, compound fertilizer, and bio-organic fertilizer, supporting rapid switching between different formulations to meet the diverse agricultural fertilization needs of the region.

The successful commissioning of this angled belt conveyor extrusion granulation production line in Malaysia not only demonstrates Huaqiang Heavy Industry’s comprehensive strength in customized fertilizer equipment R&D, core transfer technology innovation, and overseas project implementation, but also provides efficient and stable equipment support for the modernization of agriculture in Southeast Asia. In the future, Huaqiang Heavy Industry will continue to focus on the production conditions and needs of different regions, optimize product performance and service solutions, and provide more competitive customized solutions for global customers, allowing “Made in China” to gain greater recognition in the international market.

Process Diversification and Technological Integration

While this specific project utilizes an extrusion-based roller press granulator production line as its core, it’s important to contextualize this within the broader spectrum of fertilizer manufacturing technologies. The successful fertilizer granules compaction process demonstrated here is a highly efficient method for producing dense, low-dust granules. This contrasts with, yet complements, other prevalent methods like rotary drum granulation. The NPK manufacturing process often selects granulation technology based on raw material characteristics (powder blend vs. slurry) and desired product attributes. Drum granulation is typically suited for steam or liquid binding processes, creating granules through a tumbling and layering action.

Looking forward, Huaqiang Heavy Industry’s expertise extends across these domains. For clients with different raw material profiles or product requirements, the company offers tailored solutions such as a double roller press granulator for high-capacity compaction or a specialized organic fertilizer disc granulation production line. The disc granulator is particularly effective in the organic fertilizer manufacturing process for powdery organic materials, using a rotating inclined disc to form spherical granules through agglomeration. For operations seeking advanced organic solutions, a new type organic fertilizer granulator combining mixing, shaping, and polishing in one unit may be recommended. Ultimately, whether the need is for robust fertilizer compaction via a fertilizer compactor or for the coating and hardening stage in a comprehensive NPK fertilizer manufacturing process, the selection is driven by optimizing capital efficiency, product quality, and adaptability to local production conditions.

The Malaysia project thus stands as a testament to the effective application of compaction technology, while highlighting the industry’s move towards flexible, modular production lines that can incorporate various granulation principles—from extrusion and compaction to tumbling agglomeration—to meet the diverse and evolving needs of the global fertilizer market.

.jpg)

.jpg)