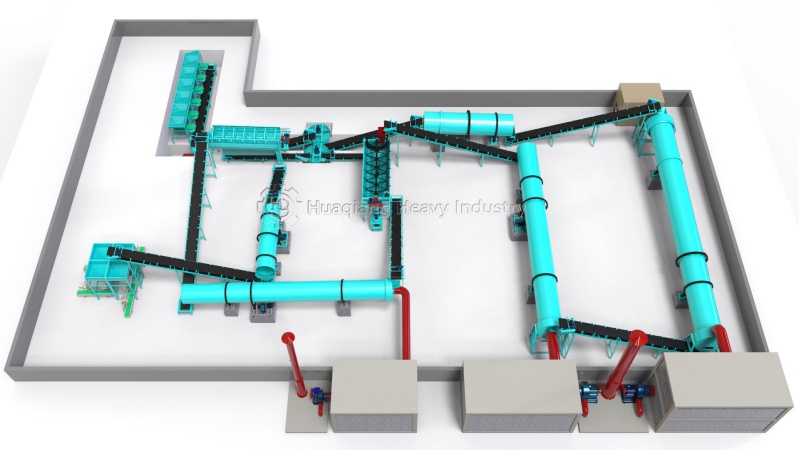

The construction of NPK fertilizer production line involves multiple key links, each of which requires specific equipment to ensure the smooth progress of the production process and product quality. Here are some key equipment in the NPK fertilizer production line:

Raw material storage equipment: used to store various raw materials such as urea, monoammonium phosphate, potassium sulfate, etc. Common equipment includes raw material warehouses, hoppers, etc.

Raw material crushing equipment: If the raw material particles are too large, a crusher needs to be used to crush them to a particle size suitable for subsequent processes. Common equipment includes hammer crushers, jaw crushers, roller crushers, etc..jpg)

Raw material conveying equipment: used to transport raw materials from storage equipment to subsequent processing equipment, including screw conveyors, belt conveyors, bucket elevators, etc.

Ingredient equipment: Accurately weigh various raw materials according to the formula to ensure the accuracy of NPK ratio. Commonly used ones include electronic scales, batching machines, etc.

Mixing equipment: Mix various raw materials thoroughly and evenly to ensure the uniform distribution of fertilizer components. Commonly used types include horizontal mixer, vertical mixer, and double shaft propeller mixer.

Granulation equipment: Mix the evenly mixed raw materials into granules. Common granulators include disc granulators, drum granulators, extrusion granulators, etc.

Drying equipment: used to remove the water added during the granulation process, ensuring the stability and quality of fertilizer particles. Common ones include rotary drum dryer, fluidized bed dryer, etc.

Cooling equipment: Cool and dry fertilizer particles to prevent clumping and improve storage stability. Common ones include drum coolers, fluidized bed coolers, etc.

Screening equipment: used to screen unqualified particles, such as particles that are too large or too small, to ensure the consistency of particle size in the final product. Common types include vibrating screens, drum screens, etc.

Packaging equipment: Quantitatively package qualified fertilizer granules, including automatic packaging machines, sealing machines, palletizing machines, etc.

Environmental protection equipment: used to treat dust, waste gas, etc. generated during the production process, including bag filters, wet dust collectors, waste gas treatment devices, etc.

Automation control system: including PLC control system, touch screen, sensors, etc., used to monitor and control the operation of the production line, improve production efficiency and product quality.

These devices form the core of the NPK fertilizer production line, and selecting the appropriate equipment type and specifications is crucial for the efficient operation and product quality of the production line. When planning a production line, it is necessary to select and configure equipment reasonably based on actual production needs, raw material characteristics, production capacity requirements, environmental standards, and other factors to achieve the best production effect.

.jpg)

.jpg)

.jpg)