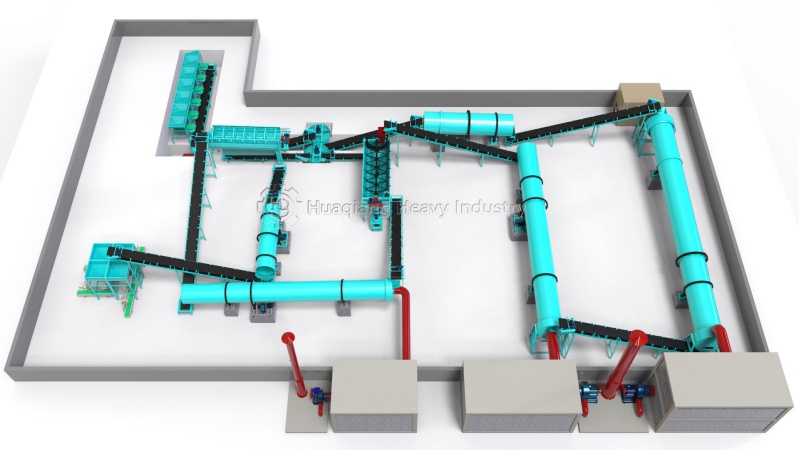

Organic fertilizer production lines have significant advantages in organic fertilizer production and are widely used in agriculture, horticulture, forestry, and other fields..jpg)

Advantages:

Resource recycling: Transforming organic waste into efficient organic fertilizers to achieve resource recycling.

Environmental Protection: Reduce the pollution of organic waste to the environment and improve the ecological environment.

Efficient: Automated organic fertilizer production line improves production efficiency and reduces production costs.

Improving soil quality: Organic fertilizers increase soil organic matter, improve soil structure, and enhance water and fertilizer retention capacity.

Application:

Agriculture: used for producing organic fertilizers, biological fertilizers, compound fertilizers, etc., to improve crop yield and quality.

Horticulture: Used for producing specialized fertilizers for flowers and vegetables to promote plant growth.

Forestry: Used for producing specialized fertilizers for forest trees to promote their growth.

Ecological restoration: used for producing specialized fertilizers for ecological restoration and improving soil environment.

Case analysis:

After a certain organic fertilizer production enterprise introduced an organic fertilizer production line, the production efficiency increased by 30%, the product qualification rate increased by 20%, and the market share significantly increased.

Conclusion:

The organic fertilizer production line, with its advantages of resource recycling, environmental protection, and high efficiency, is widely used in agriculture, horticulture, forestry, and other fields, promoting the development of the organic fertilizer industry.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)