Dry granulation extrusion technology has become a mainstream technology in fertilizer production due to its advantages of no high-temperature drying, minimal nutrient loss, energy saving, and environmental friendliness. Based on its physical extrusion molding characteristics, it is suitable for various types of fertilizers, balancing large-scale production and product quality.

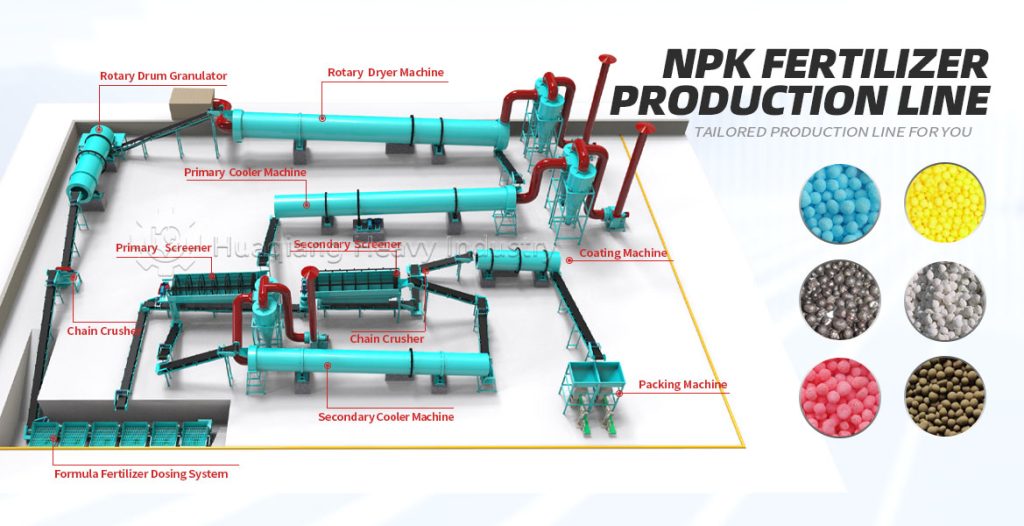

It is best suited for compound fertilizers (including NPK compound fertilizers), allowing for precise mixing of nitrogen, phosphorus, potassium, and trace elements. After extrusion molding with a fertilizer compaction machine, the nutrients are evenly distributed, avoiding the loss of heat-sensitive nutrients. It is suitable for the production of medium and low-concentration products, meeting the balanced fertilization needs of field crops, and the granules have moderate strength, facilitating storage and transportation.

Organic-inorganic compound fertilizers are also a core application. It can mix and extrude dried organic fertilizer powder with inorganic fertilizer raw materials, combining the soil-improving advantages of organic fertilizers with the rapid fertilization characteristics of inorganic fertilizers, solving the problems of difficult molding and easy caking of organic raw materials, and is suitable for various crops such as fruits, vegetables, and seedlings.

In addition, this technology can produce special fertilizers and single-element fertilizers, such as granular fertilizers for saline-alkali soil improvement and trace element-specific fertilizers, achieving targeted nutrient supply; it can also be used for molding single-element fertilizers such as urea and potassium chloride, improving product uniformity and reducing transportation losses.

This fertilizer granule extrusion technology has moderate requirements for raw material temperature, humidity, and particle size, and does not require a large amount of binder for molding, meeting the needs of green production and being suitable for various production scales.