Have you ever been curious about the fascinating journey of organic waste transforming into valuable biofertilizer? This remarkable metamorphosis occurs through bio organic fertilizer production – a meticulously organized process that relies on specialized equipment at each stage to create high-quality end products.

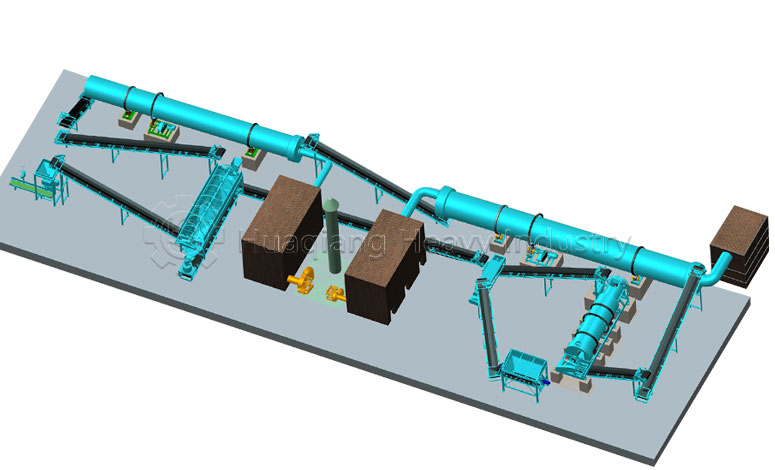

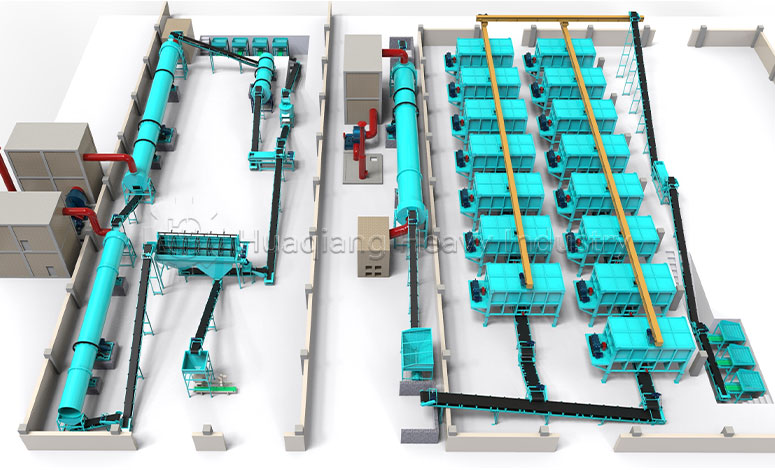

The complete organic fertilizer production line begins with raw material preparation, where organic waste is composted and treated. The heart of the operation features a fertilizer mixer machine that ensures uniform blending of ingredients, followed by granulation using specialized equipment like a disc granulator or other types of fertilizer granulator that shape the material into consistent, easy-to-handle pellets.

Interestingly, while NPK fertilizer production line configurations often prioritize chemical precision, bio-organic lines focus on preserving natural nutrients and microbial activity throughout the manufacturing process. The journey concludes with automated packaging through a fertilizer packing machine that ensures product integrity from production to field application.

Each piece of equipment plays a crucial role in this sustainable transformation, working in harmony to convert waste into wealth while maintaining the vital organic properties that make biofertilizers so valuable for sustainable agriculture and soil health regeneration.It’s a well – organized process that relies on specific equipments required for biofertilizer production, and each step is key to creating a high – quality end product.

The process starts with raw material pretreatment. First, organic wastes like livestock manure and crop straw are collected. Then, a crusher – a vital fertilizer machine – breaks them down into small particles that are perfect for fermentation. After crushing, a screening machine removes any impurities, making sure the raw materials are clean. Next, the crushed materials are mixed with water and fermentation agents. This mixing step adjusts the humidity and boosts microbial activity, getting everything ready for fermentation. Sometimes, workers also flip the materials to ensure even mixing, which kickstarts the initial microbial work.

Once pretreatment is done, it’s time for fermentation – the core of the process. The pretreated materials are moved to fermentation equipment, such as fermentation tanks or turntables. These fertilizer equipments create the ideal conditions for microbes to thrive. During high – temperature fermentation, the microbes break down the organic matter. To keep things on track, workers or automated systems regularly flip or stir the materials to provide enough oxygen. They also monitor temperature, humidity, and oxygen levels closely. Adjusting these parameters ensures efficient fermentation and produces top – notch fertilizer raw materials.

After fermentation is complete, post-processing begins. First, a dryer removes excess moisture from the fermented material, improving the fertilizer’s stability and making it easier to store. Then, a granulator—another essential fertilizer equipment—transforms the dried material into granules. These granules are convenient for transportation and use. Next, a sieving machine classifies the granules, removing oversized and undersized particles. Finally, a mixer blends qualified granules with additives such as microbial preparations and trace elements to enhance the fertilizer’s nutritional value and biological activity.

The last steps are packaging and storage. An automatic packaging machine – a time – saving fertilizer equipment – packs the finished biofertilizer into bags or boxes. Before sending the products out, strict quality inspections are carried out to make sure they meet national or industry standards. Every step, from start to finish, shows how important each fertilizer machine and equipment is in the biofertilizer production line!