Pig manure has a high nutrient content and can improve soil fertility after use. The problem of fecal pollution in large-scale pig farms has attracted strong social attention. Under environmental pressure, more and more farms are starting to solve it, attempting to change the current passive situation. Practice has proven that using pig manure to produce organic fertilizer is a relatively effective harmless treatment and resource utilization method for large-scale breeding farms.

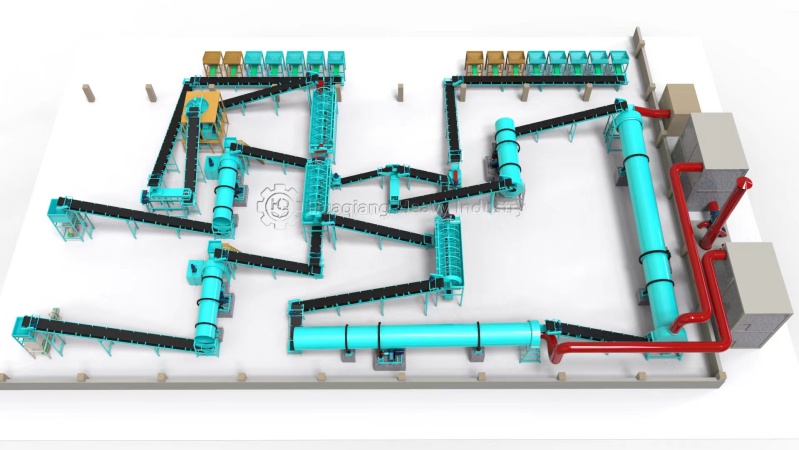

The process flow of producing organic fertilizer from pig manure organic fertilizer production line

Crush, mix, and mix various raw materials such as composted pig manure organic fertilizer, nitrogen, phosphorus, potassium inorganic fertilizer, and other additives in proportion.

The organic fertilizer granulator is suitable for direct granulation of pig manure organic fertilizer after fermentation. Before granulation, the raw materials do not need to be dried, and after crushing, the raw materials can be directly mixed to produce spherical pig manure organic fertilizer particles. The moisture content of the raw materials can be between 30% -40%, and the pelletizing rate can be above 96%.

The pig manure organic fertilizer pellets output from the granulation system have certain differences in particle size and need to be screened and graded. The selected rotary screening machine requires low vibration, low noise, convenient screen replacement, and is equipped with a screen cleaning device. It is recommended to equip an automatic feeding system to screen out unqualified large and small particles, transport them out through a belt elevator, re crush them, and send them to a granulator for further granulation, which helps to improve the continuous operation capacity of the production line.

The function of the pig manure organic fertilizer dryer is to further remove moisture from the screened pig manure organic fertilizer particles and meet the standard requirements for organic fertilizer moisture content. Particle drying generally uses a drum dryer to improve particle formation while drying.

The dried pig manure organic fertilizer particles are transported by a belt to a cooling machine. The rotary cooling machine is also a rotating cylinder filled with lifting pallets. Under the action of the pallets, the granulated materials are lifted and heat exchanged with the cold air sucked into the cylinder, cooled to near room temperature, further improving particle strength and reducing moisture.

After the pig manure organic fertilizer granules are cooled, they can be used as bio organic fertilizer, compound microbial fertilizer and special organic fertilizer. They can spray attachments to the coating machine through the self-priming spray equipment to improve the appearance or internal quality of the product.

Pig manure organic fertilizer pellets are quantitatively weighed and packaged using an automatic packaging scale. The automatic packaging scale adopts microcomputer control, which can achieve multi range measurement. It has high weighing accuracy, automatic clamping, sewing, automatic tare weight removal, and detection functions. Its advantages are incomparable to manual packaging.

.jpg)