Organic fertilizer fermentation equipment is widely used in organic fertilizer production, which can improve production efficiency and produce high-quality organic fertilizer. Before the production of organic fertilizer, manure should be treated to achieve the best effect.

Mode of manure treatment of organic fertilizer

1. Dry chicken manure mode

Its technological process is that chicken manure is directly through high temperature, heating, sterilization and drying, and finally dried chicken manure with water content of about 13% is sold directly as a product. Many manufacturers adopt this mode of production,

The advantages of this mode are: 1. Large production and fast speed; 2. Stable product quality and low moisture content.

But at the same time, there are also shortcomings: 1. The tail gas produced in the production process pollutes the environment. 2. The energy consumption in the production process is high, and the energy consumption per ton is about 200 yuan. 3. The quality of the product is not reliable because of its dry surface, bad smell and secondary fermentation after soaking in water. 4. The equipment investment is large and the utilization rate is not high. 5. The organic matter content in chicken manure is not up to the standard.

2. Direct drying mode

Its main technological process is to spread chicken manure directly in the air, after drying, crushing and packaging directly as a product for sale.

The advantages of this mode are: low cost and simple operation.

But it also has disadvantages: 1. It occupies a large area and pollutes the environment. 2. There is also a problem of seasonality and seasonality in air drying, so the fertilizer production line can not be produced continuously through factory. 3. It is difficult to guarantee the quality of the product due to its large volume, low nutrient content and secondary fermentation.

3. Compost fermentation mode

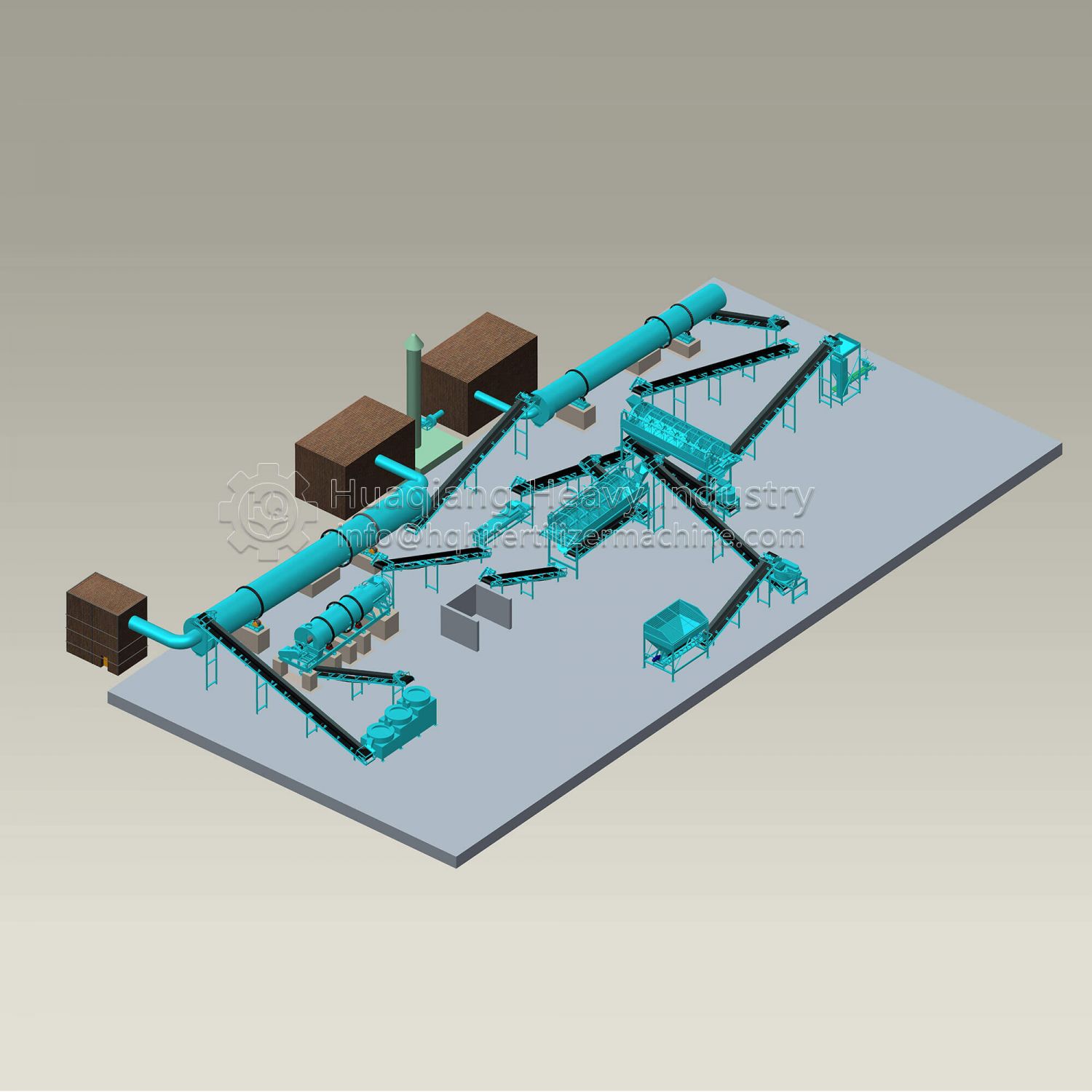

Manure compost fermentation is the main treatment method of organic fertilizer production line. The requirements of compost turning machine are not high. When tank fermentation is selected, the materials suitable for moisture adjustment are laid in the fermentation tank of solar composting workshop. After high temperature fermentation, the harmful substances in raw materials are killed to ensure the safety of fertilizer. At the same time, the decomposed compost is further made into high-quality fertilizer by the organic fertilizer granulator machine in the fertilizer production line.