What equipment does the annual production line of 20000 tons of cow manure organic fertilizer belong to a medium to large scale?

1、 Fermentation equipment

The fermentation process plays a crucial role in the production of organic fertilizers, and can even determine the quality of organic fertilizers. There are two common fermentation equipment in an organic fertilizer production line with an annual output of 20000 tons:

1. Fermentation tank

Fully sealed fermentation, with a small footprint, low environmental pollution, and high fermentation efficiency, is very suitable for use in small fermentation sites with strict environmental protection. And the fermentation tank has an insulation device, so it can be used normally even in the cold winter in the north.

The trough type flipping equipment requires the construction of a fermentation tank, which is usually indoors and is commonly used in environmentally strict and rainy areas. The equipment includes chain plate flipping machine, disc flipping machine, slot flipping machine, etc. The equipment has a large processing capacity, high degree of automation, and does not require manpower. Very suitable for medium to large organic fertilizer equipment factories.

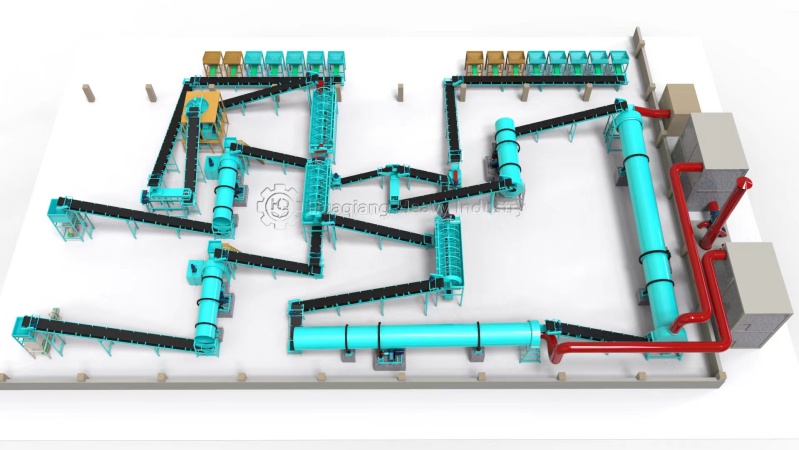

2、 Cow manure manure fertilizer making equipment

Due to its suitability for agricultural production, granular organic fertilizers are quite popular in the market. A production line with an annual output of 20000 tons is relatively large, and it is recommended to equip it with granulation equipment.

The fertilizer making equipment mainly includes crushers, screening machines, granulators, dryers, cooling machines, packaging machines, etc. Except for the various types of granulation equipment, the other types of equipment are relatively single, with only differences in specifications and sizes.

The granulation equipment mainly includes rotary granulator, toothed granulator, disc granulator, flat mold granulator, etc. Suitable equipment can be configured according to the actual situation of the site, finished product form, etc.