Selection of fertilizer screening machine

The selection of screening machinery and equipment is a more troublesome process, but in fact, as long as we have a good understanding in advance, it is not difficult to select the drum screening machine suitable for NPK fertilizer manufacturing process.

As long as the characteristics of their own materials, dry and wet degree, screening accuracy and proportion of materials to do a good understanding, you can master a good method. Here is a brief introduction to the selection of this screening machine in the procurement.

Take chemical fertilizer as an example, there are many kinds of chemical fertilizer, with different material characteristics, such as particle size, powder size, viscosity, non viscosity, etc., so there are many kinds of vibration screening machines for chemical fertilizer screening. For example, the large particle urea screen is not only a fine screening machine, but also can be called plane reciprocating screen, fertilizer grading screen, etc. generally, the most commonly used screening machines for fertilizer are fine screening machine, drum screening machine, linear vibrating screen, etc.

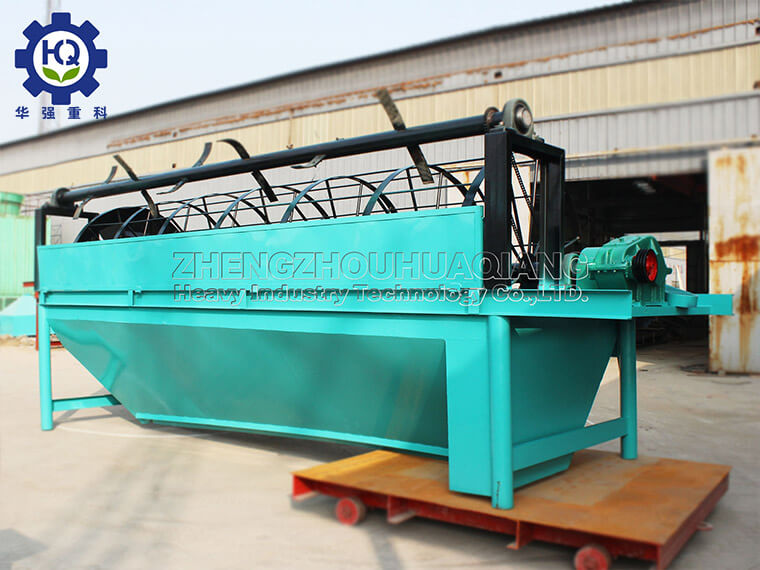

Fertilizer drum screening machine

Rotary drum screener is mainly used for the screening and grading of chemical large-particle urea, powdered materials in feed mills, or pellet feed. It can also be used for the primary cleaning of raw materials in feed mills and the grading of intermediate products after secondary crushing in large and medium feed mills. Moreover, in the fertilizer manufacturing process, the granules processed by the NPK fertilizer granulator can also be accurately screened.

In addition, the rotary drum screening machine can also be widely used in the screening and grading of raw materials and finished products in various industries such as grain, food, chemical, sugar, mining, and papermaking.