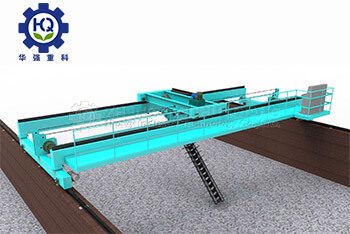

For Organic fertilizer fermentation equipment, the trough dumper is a large machine used for tipping materials in fermentation tanks. It is mainly composed of walking system, lifting mechanism, rack, working parts, power transmission system, and tipping working parts. In order to flip multiple fermentation beds, the dumper should be used in combination with the shifter. The traveling system is composed of traveling frame, traveling motor, chain transmission system, transmission shaft, traveling wheel, etc., which is used to drive the Organic fertilizer composter to move on the track; The lifting mechanism uses hydraulic cylinders to lift and lower the working components in order to adjust the flipping depth; The rack provides installation positions and support for motors, hydraulic systems, electrical cabinets, etc; The power transmission system of the working component is composed of a motor, a T-shaped transmission box, a reducer, a chain transmission system, etc., which transmits the motor power to the working component to provide power for the working component. During the forward process of the machine, the working component throws the material from bottom to top through the rotating motion of the rake teeth, making it fully in contact with the air.

Maintenance of livestock manure Organic fertilizer composter

1. Anti aging. Rubber or plastic products are prone to aging and deterioration due to the effects of oxygen in the air and ultraviolet radiation from sunlight, resulting in poor elasticity and easy breakage of rubber parts. For the storage of rubber parts, apply hot paraffin oil to the surface of the rubber, place it on an indoor shelf, cover it with paper, and maintain ventilation, dryness, and protection from direct sunlight.

2. Anti deformation. Springs, transmission belts, tires, and other components may undergo plastic deformation due to long-term stress or improper placement. Therefore, appropriate support should be provided under the frame; Make the tire not bear the load; All springs that are pressed or pulled apart mechanically must be relaxed; Remove the transmission belt and store it indoors properly; Some easily deformed parts that are removed need to be placed flat or hung vertically; In addition, when storing dismantled parts such as tires and seed delivery pipes, it is necessary to prevent compression deformation.

3. Loss prevention. A registration card should be established for long-term parking equipment, detailing the technical status, auxiliary devices, spare parts, tools, etc. of the equipment; Various machines and tools should be kept by dedicated personnel; It is strictly prohibited to disassemble parts for other purposes; If there is no warehouse, when machines and tools are parked outdoors, easily lost parts such as motors and transmission belts should be removed and marked, and stored indoors.