With the continuous development of China’s economy, organic fertilizers have gradually become popular among farmers and are an indispensable part of the development of the organic green industry. Of course, they are also more in line with the current national policy guidance. Therefore, the quality of organic fertilizer production equipment is also the top priority of development needs. It not only allows organic fertilizer processing enterprises to make better profits, but also brings more practical and efficient commodity organic fertilizers to farmers. Chicken manure is a very good raw material for organic fertilizers. The production of organic fertilizers using chicken manure is mainly divided into two parts: pre fermentation and post processing. The pre fermentation part is a necessary processing step for any form of organic fertilizer, and a fermentation tipping machine is needed to assist in the processing process. The later processing process mainly selects the corresponding production equipment based on the type of fertilizer you need, such as a crusher and screening machine for powdered organic fertilizer. Granular organic fertilizer requires the addition of granulators, dryers, and cooling machines on top of the previous ones.

Specific fermentation process of organic fertilizer fermentation equipment

1. Mix the fermentation agent well. Add 2 tons of dry chicken manure (about 3-4 tons of fresh chicken manure) and one bottle of Nongfukang chicken manure starter. Add an average of 100 kilograms of rice bran, corn, and bran to each bottle of chicken manure starter. Stir well and sprinkle into the prepared material for the best effect.

2. Adjust the carbon nitrogen ratio. The carbon to nitrogen ratio of fermented fertilizers should be maintained at 25-30:1, and the pH should be adjusted to 6-8 (ph). Due to the high carbon to nitrogen ratio of chicken manure, some straw, straw, mushroom residue, etc. should be added during fermentation to ferment together.

3. Adjust the moisture content of chicken manure. During the process of fermenting organic fertilizers, it is very important to determine whether the moisture content is suitable. It should not be too high or too low, and should be kept at 60-65%. The judgment method is to tightly grasp a handful of materials, see watermarks on the fingertips but do not drip, and it is advisable to scatter them on the ground.

4. Build a pile of chicken manure. When making a fermentation pile, it should not be too small or too short, as it will affect fermentation. The height of the pile is generally around 1.5 meters, the width is about 2 meters, and the pile with a length of 2-4 meters or more has a better fermentation effect.

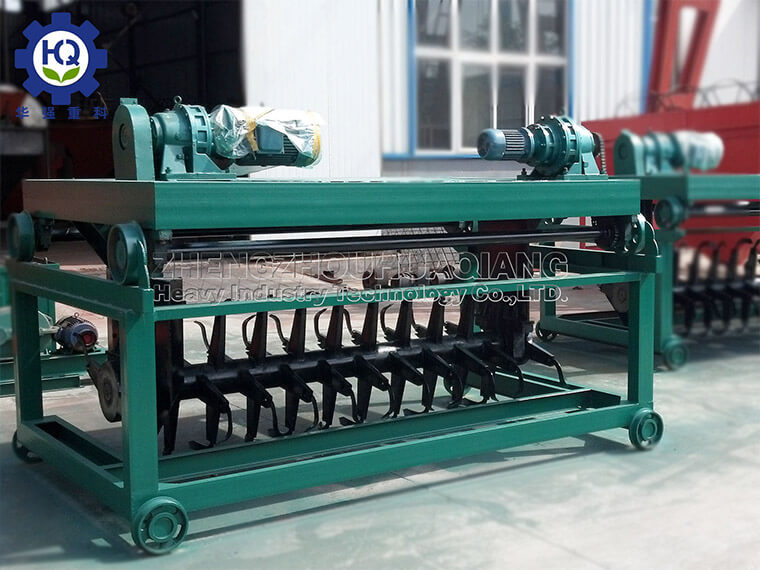

5. Mix well and ventilate. The Nongfukang chicken manure fermentation agent is an aerobic microorganism, so oxygen supply measures should be increased during the fermentation process, ensuring that it is well mixed, frequently turned over, and ventilated, otherwise anaerobic fermentation will affect the material fermentation effect.

6. Fermentation completed. Generally, after 48 hours of chicken manure accumulation, the temperature will rise to 50-60 ℃, and on the third day, it can reach over 65 ℃. Under this high temperature, it will be overturned once. Generally, during the fermentation process, there will be 2-3 times of high temperature above 65 ℃, which can be overturned 2-3 times to complete the fermentation. Normally, the fermentation can be completed in about a week, allowing the material to completely deodorize, ferment and mature, and sterilize and kill insects.

The organic fertilizer fermentation equipment ferments crop waste and livestock waste, such as straw, corn cob, distiller’s grains, chicken manure, pig manure, and other animal manure containing organic substances, to produce organic fertilizer containing a large number of microbial strains through fermentation. The ripening process can promote the decomposition of organic fertilizers, increase the effective components in the fertilizers, and kill bacteria, insect eggs, and weed seeds through high-temperature fermentation, making organic fertilizers safe, efficient, and pollution-free.