If non composted decomposed manure directly enters farmland, it will consume the oxygen in the soil of crop roots, produce high-temperature combustion of crop roots (usually referred to as burning seedlings), produce harmful substances of pathogens, not only fail to achieve the expected production effect, but also cause secondary pollution of soil, water, atmosphere, and agricultural products, posing serious risks to food safety production and ecological environment.

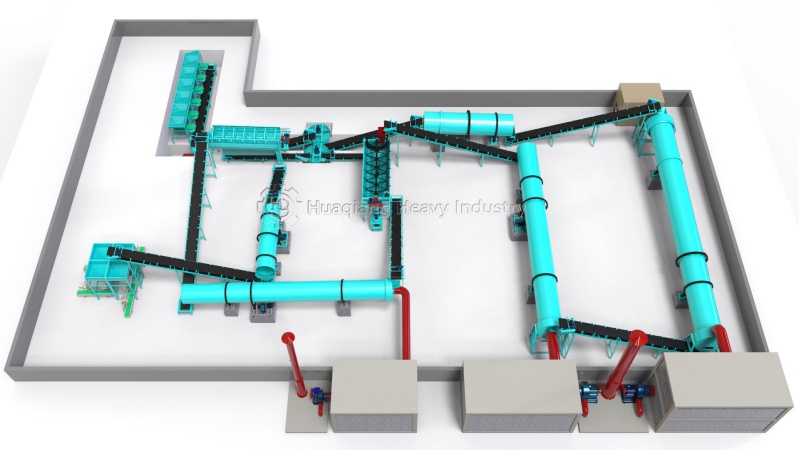

A complete set of equipment for processing poultry manure organic fertilizer production line usually includes the following main parts:

Fermentation and flipping equipment, feeding machine, crushing equipment, screening equipment, granulation equipment, drying equipment, cooling equipment, packaging equipment, dust removal equipment, etc. These are the basic equipment, and the specific configuration needs to be selected based on production capacity, operation time, site, and finished product shape.

Among them, the vertical crusher is mainly used for preliminary crushing of poultry manure, while the chain crusher is used for further crushing of poultry manure for better composting. The dual axis continuous mixer is used to thoroughly mix poultry manure with other organic materials, ensuring even distribution of nutrients.

The turner is used to compost the mixed materials and promote their fermentation into organic fertilizer.

The drum screening machine is mainly used to screen out organic fertilizers with uniform particles to meet the needs of different uses. Finally, the packaging machine is used to package organic fertilizers for sale on the market.

Poultry manure is roughly crushed through a vertical crusher, and then finely crushed through a chain crusher. Next, mix the finely ground poultry manure with other organic materials to evenly distribute nutrients. Subsequently, the mixed material is sent to the composting machine for composting treatment. During the composting process, the material gradually ferments into organic fertilizer. After completing the composting, the organic fertilizer is screened out by a drum screening machine to obtain uniform particles of organic fertilizer. Finally, the selected organic fertilizers will be packaged using a packaging machine for sale and use.