The process of using an organic fertilizer granulator to process cow manure into fertilizer can be summarized as a series of carefully designed steps aimed at transforming the original agricultural by-products into high-quality organic fertilizers. The following is the basic process of this process:

1. Collection and pretreatment of cow manure

Collection: Regularly collect fresh or matured cow manure from the cowshed or composting area.

Preprocessing: Remove large debris such as stones, metal fragments, etc., and sometimes adjust the humidity of cow manure. Generally, it needs to be controlled between about 40% -60% to facilitate subsequent processing.

2. Fermentation and maturation

Composting: Stacking cow manure and conducting natural or temperature controlled fermentation through the action of microorganisms. During this process, a turning machine may be used to promote ventilation and accelerate the composting process.

3. Drying

Use a dryer or natural air drying to further reduce the moisture content of cow manure to approximately 15% -20%, making it easier to pelletize and store for a long time.

4. Crushing and mixing

Crush the fermented and dried cow manure to achieve the required fineness for granulation.

According to the formula requirements, add an appropriate amount of auxiliary materials such as sand, peat, microbial agents, etc., and mix evenly.

5. Granulation

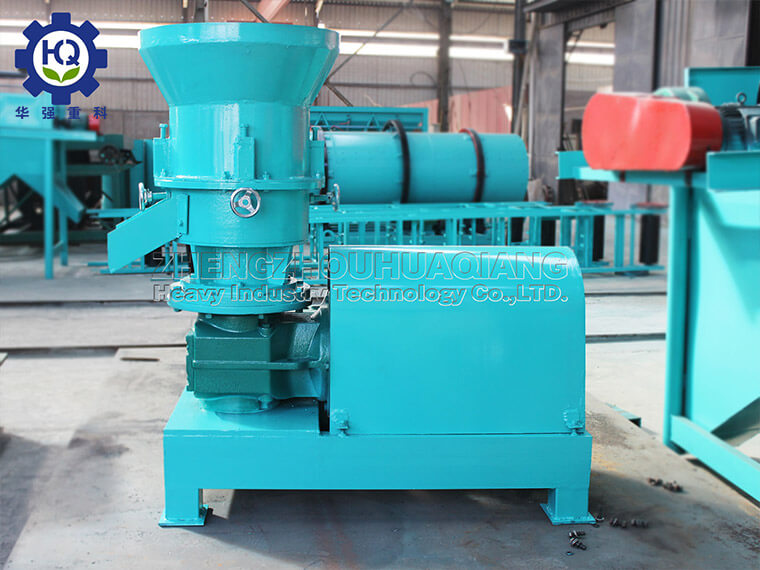

Use organic fertilizer granulators, such as roller extrusion granulators or disc granulators, to compress the mixed materials into granules. Roll granulators are suitable for drying materials, while disc granulators are suitable for materials containing a certain amount of moisture.

6. Cooling and hardening

Freshly produced particles may need to be cooled by a cooling machine to increase hardness and prevent deformation or cracking.

7. Screening

Remove oversized or undersized particles through a vibrating screen to ensure consistent particle size in the finished product.

8. Packaging and Storage

The final step is to quantitatively package qualified organic fertilizer granules, seal and store them, and prepare them for distribution to retailers or direct sale to farmers.

Pay attention

Quality and safety testing: Prior to packaging, necessary chemical analysis is conducted to ensure that the nutritional composition and safety of the finished fertilizer meet industry standards.

Cleaning and Disinfection: Regularly clean and disinfect production equipment to reduce the risk of bacterial and viral transmission.

The use of organic fertilizer granulators to process cow manure not only effectively converts agricultural waste, but also produces fertilizers rich in organic matter and essential trace elements, which have a positive effect on improving soil structure and increasing crop yields. It is an important part of modern agricultural circular economy.