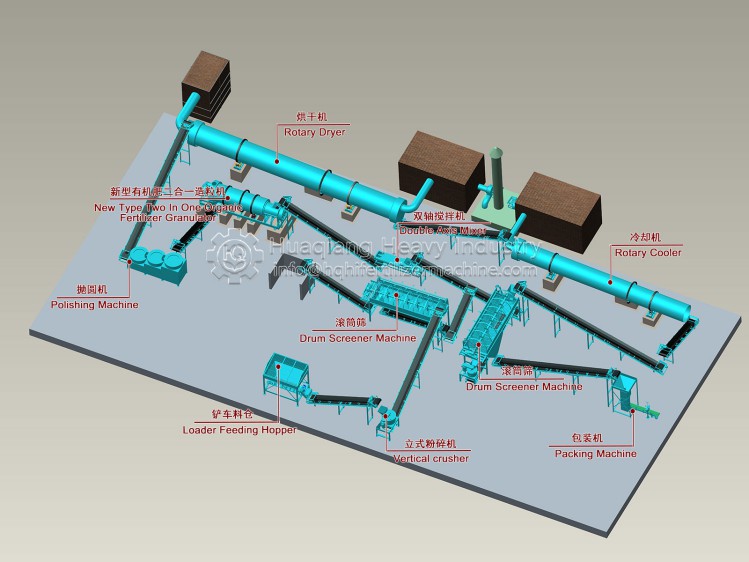

Organic fertilizer production line configuration requires smooth equipment layout, compact structure, save space as much as possible, and reduce construction civil investment; adapt to the characteristics of cow dung material, durable equipment, small maintenance, low system energy consumption, low operating costs; convenient equipment operation, minimize Manual operation errors reduce labor intensity.

1) Compost turning machine; its equipment is used for fermentation and stacking of materials, and this type of equipment has the advantages of high fermentation material accumulation, large dumping output, and complete material transfer. It is suitable for large-scale organic fertilizer fermentation and is a land cost. It’s ideal for high organic fertilizer manufacturers.

2) Double-shaft horizontal pulverizer; its function is to pulverize the fermented materials to achieve uniformity. The equipment also has the advantages of reasonable structure, convenient installation, high efficiency, significant energy saving, durability and easy maintenance.

3) Horizontal mixer; the function of its equipment is to crush, mix and mix various materials such as crushed materials and NPK inorganic fertilizers and other additives in a certain proportion.

4) Disc granulator; the function of the fertilizer granulator machine is to granulate the materials that are mixed and stirred uniformly, and to shape the materials. Its advantages are that it is suitable for farming raw materials, especially suitable for organic materials, and has stable granulation, high particle forming rate, and the appearance of finished particles is uniform and difficult to break.

5) Drum dryer; its equipment is used to further remove the moisture content inside the processed material particles to achieve the moisture content standard.

6) Rotary cooler; the function of this equipment is to cool the dried granular material. Because the dried material temperature is too high, it is not easy to save, so it needs to be processed by cooling machine, and the cooled granular material is convenient for storage and quality.

7) Drum screening machine; the size of the granulated materials produced from the granulation molding program will have a certain difference, so it needs to be processed by a screening machine to screen out unqualified granules for secondary crushing.

8) Automatic packaging machine; the material granules processed in series can be transported to the equipment by the hoist for final weighing and packaging. The automatic packing scale is controlled by microcomputer, which can realize multi-range measurement with high weighing accuracy Automatic bag clamping, sewing bag, automatic tare and detection functions, its advantages are unmatched by manual packing.